Hot-dip galvanized bolts are bolts that are coated with a layer of zinc on the surface to protect the metal inside. This zinc layer is formed through the process of dipping the bolt into a molten zinc bath. During the galvanizing process, the metal is alloyed with the substrate. Therefore, the zinc-plated layer will not peel off like when using paint, creating a permanent protective layer for the substrate. See the article below to better understand this material as well as how much hot-dip galvanized bolts cost.

Hot-dip galvanizing technology for bolts

Hot-dip galvanizing technology was first introduced in 1742 by French chemist Melouin during a presentation at the French Academy. Over time, along with the general development of the world, the hot-dip galvanizing industry has made continuous progress in increasing the quality and aesthetics of products. This method has been widely applied in almost every industry of the economy, such as construction, mechanics, power transmission, transportation, paper mills, chemical plants, oil and gas rigs, etc.

In Vietnam, it was not until 1989 that hot-dip galvanizing technology began to be researched and put into production and was strongly promoted when constructing the 500 kV North-South power transmission line for the cause of industrialization. modernize the country. Corresponding materials and zinc-dip technology were applied at the right time, meeting anti-corrosion requirements and improving the quality and longevity as well as the safety of bolts and steel structures.

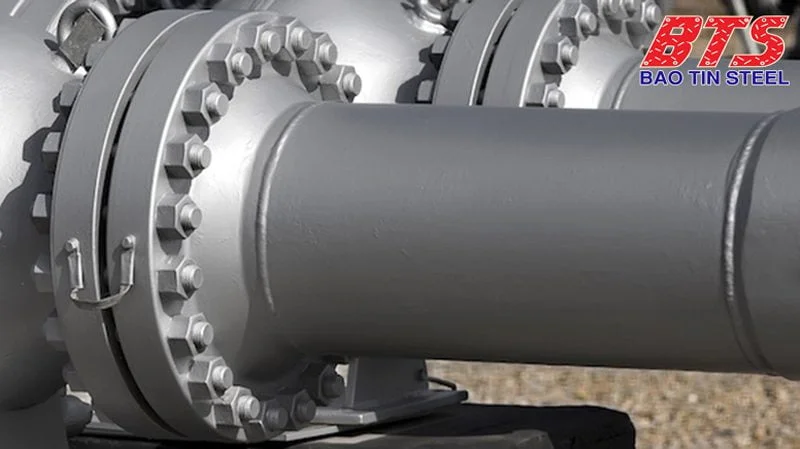

Subjects of application are mainly projects with large steel structures such as oil and gas drilling rigs, bridge girders, steel building girders, high steel column structures, hydroelectric dam gate systems, sluice gates, ship hulls, and buildings. steel.

Why choose the hot-dip galvanizing method?

Before learning about the price of this type of bolt, we need to understand why the hot-dip galvanizing method is applied to so many types of materials. With the outstanding advantages of protective surface coating, this technology shows useful values. It ensures the structural quality of construction steel bolt connection projects during the period of industrialization and modernization in the country.

– Creates a protective layer for metal structures in air, sea, and industrial gas environments…

– Restores worn parts: renews the product surface when affected by environmental factors.

– Create a durable, wear-resistant layer on new parts.

– Create decorative layers on plastic, wood, etc.

– The most popular is still creating anti-corrosion zinc and aluminum layers in different conditions.

Production process

Using protective coatings (also called barrier protection) to isolate metal surfaces in contact with capacitive substances in the external environment is the oldest and most widely used method of corrosion protection. trail. The two most important properties of a barrier protection layer are adhesion to the base metal surface and the durability of the coating. Paint is a good example of a protective barrier.

The second function is active protection, which is the anti-cathode anti-corrosion function (cathodic protection). This function is found in the protective coating made of hot-dip galvanizing.

See more: How are hot-dip galvanized steel pipes produced?

Production Standard

+ ISO, JIS, and DIN standards are based on the metric system and are closely related to the production of bolts and screws (according to ISO 261 guidelines). Most technical equipment is measured in metric units according to the Society of Automated Engineering (SAE) standard. These standards are popular in most countries around the world, and it can be seen that this could become a global technical equipment standard. Twisted threads on bolts and screws can meet thread design standards, meeting both fine and coarse threads.

+ With American standard bolts and screws, bolt manufacturers will comply with the proportional size of the screws. North American countries manufacture according to this system, called the “Thread Unified Standard.” The calculation method will be “threads per inch” (TPI).

+ Bolts and screws comply with both British and American measurement units, and there is a clear contrast in the way screws are made. Screws are produced in rough thread form, which is the method of creating screw threads and does not reflect the quality of the product. Coarsely threaded bolts are less susceptible to tarnishing, splitting, and jamming, while finely threaded bolts are unlikely to loosen and are easier to tap and adjust..

Price of hot-dip galvanized bolts

Currently, there are many sellers of this type of material, including Bao Tin Steel. Depending on the source of goods and accompanying services, you will see that the price of galvanized bolts is somewhat different. To make it easier for you to visualize and estimate, we would like to send you the hot-dip galvanized bolt price at Bao Tin Steel. In particular, one product set will include body, ecu, and temple.

Specifically:

As mentioned above, this is only a reference price. Customers who need to choose to buy the above product or need further support about the price of this bolt can contact Bao Tin Steel at Holtline: 0932 059 176.

Where do you sell quality hot-dip galvanized bolts?

With the current diverse developments in the market, finding and buying quality hot-dip galvanized bolts at good prices is not simple. There are many forms of purchasing, such as online or going to agents or manufacturing facilities. If you are looking for a place to sell bolts and screws in large quantities and are wondering about a company that produces and processes cheap hot-dip galvanized bolts in Ho Chi Minh City, please come to us at Bao Tin Steel.

- Bao Tin Steel Company is a supplier of quality hot-dip galvanized bolts. Products are always available and designed according to customer needs.

- We have skilled staff and designers with many years of experience. At the same time, we are constantly researching and manufacturing cheap and high-quality bolts and screws.

- Own a factory with modern machinery and technology to promptly meet all customers’ needs.

Above is information about hot-dip galvanizing technology and the price of hot-dip galvanized bolts. Hopefully, the information from Bao Tin Steel has helped you better understand this material and get a reputable and quality purchasing address. Contact us now if you want to order!

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ