Steel pipe welding is a technique applied to many industries, including construction and pipe repair. It requires strict requirements for weld quality, durability, and safety when performed. So, what steps does the steel pipe welding process include? What should be noted? See the answer now in Bao Tin Steel’s article!

Popular steel pipe welding methods

Currently, there are many methods of welding steel pipes in use. Among them, there are 5 popular methods such as:

Manual arc welding (MMA)

Gas metal arc welding (MIG/MAG)

This method uses an arc created from molten electrode wire that is automatically supplied to the welding part. This arc will be protected by a stream of inert or reducing gas, preventing the metal from oxidizing.

This type of pipe welding is suitable for automatic and semi-automatic welding. It produces quality welds with little smoke and slag. However, to do this, we need specialized equipment and protective gas.

Gas Tungsten Arc Welding (TIG)

This steel pipe welding method uses a non-melting tungsten electrode and an inert gas to help protect the metal layer. It also meets pipe welding standards well, such as MIG or MAG welding. It creates beautiful, highly accurate welds with little distortion.

TIG welding is used to weld stainless steel, aluminum, copper, and alloys. However, it requires welders to be highly specialized and skilled. At the same time, the speed is also slower than other methods.

Submerged arc welding (SAW)

SAW welding is a method of using molten welding wire and powdered solder to create an arc. It produces quality welds. less smoke and welding slag. In particular, it can weld automatically at high speed.

This method is often used with large pipes that need to weld many long joints. For example, there are types of spiral-welded steel pipes. However, to weld, it is necessary to prepare specialized machinery and solder iron.

Weld the spring

This method uses a steel spring to force the two pipes together. At the same time, the edge of the tube is heated electrically. This method helps meet steel pipe welding standards. Specifically, it creates tight welds with almost no weld defects. And there is also no need to use welding materials.

It is suitable for small pipes or heat-sensitive materials. However, it requires high investment costs and specialized welding equipment.

It can be seen that the steel pipe welding technique is used largely in the production process of welded steel pipes. If you don’t know, welded pipes are made from welding steel sheets or steel plates that have been bent or pre-shaped. You can learn more about this type of pipe through the article: Welded steel pipes: All you need to know about standards and specifications.

Steel pipe welding technique

The steps for welding steel pipes are not too complicated. Immediately refer to the steps below to ensure steel pipe welding standards.

Prepare the welding machine

Welding machines are the most important equipment when applying steel pipe welding construction methods. Before starting welding, you need to make sure the welding iron, gas source, and power source (voltage). You can test the solder first to adjust the voltage level accordingly.

Normally, the current for pipe welding will be about 100–150. Depending on the size of the pipe, welding material, and welding method, you can adjust the above current appropriately.

To weld large-diameter steel pipes, you also need to prepare large compensation rods (4–5 mm). At the same time, the current must also be strong enough so that the welding rod can flow evenly when welding.

Prepare the workpiece for welding

Welding workpieces greatly affect the quality of the weld as well as the efficiency of the steel pipe welding process. When choosing this blank, you need to check and make sure the blank is clean and has no cracks or rust; no dirt, grease, etc.

Cut to the appropriate shape and size. Next is shaping the workpiece (bending, chamfering, etc.) as required.

Carry out welding for steel pipes

- Place a pipe on the jig table, turn the beveled edge up, and use a “U”-shaped welding rod to align the gap.

- Place the other tube on top; the two beveled edges are joined together to form a weld groove. Adjust so that the deviation between the two welded edges is at most 1.6 mm.

- Weld symmetrically through the center of the tube (10–15 mm).

The tack welding technique requires good penetration into the root and penetration into the 1.6 mm joint. In the first two welds, when welding, pay attention to moving the gap spacer to avoid distortion. The 3rd and 4th welds are perpendicular to 90 degrees from welds 1 and 2. It is necessary to grind the welds properly so that the penetration meets the standards of steel pipe weld joints.

To save time, you can make a jig from rectangular rails. Note that this bar is sized to fit and fits tightly to the tube body. Once you have the jig, place the two pieces of pipe on the rail. These two tubes are 2 mm apart. Finally, you insert the compensation rod and attach the weld. This way, at the same time, you can weld four joints opposite each other.

Conduct layer welding or lining welding for steel pipes.

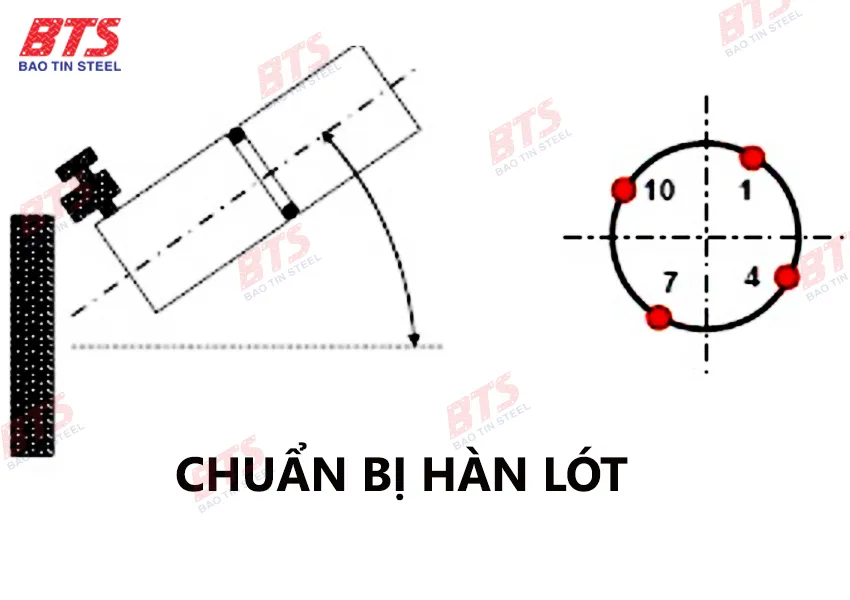

Along with the welds at positions 1 o’clock, 4 o’clock, 7 o’clock, and 10 o’clock (clockwise), we clamp the weld sample securely in a position that creates a 45-degree angle with the ground.

+ For TIG welds

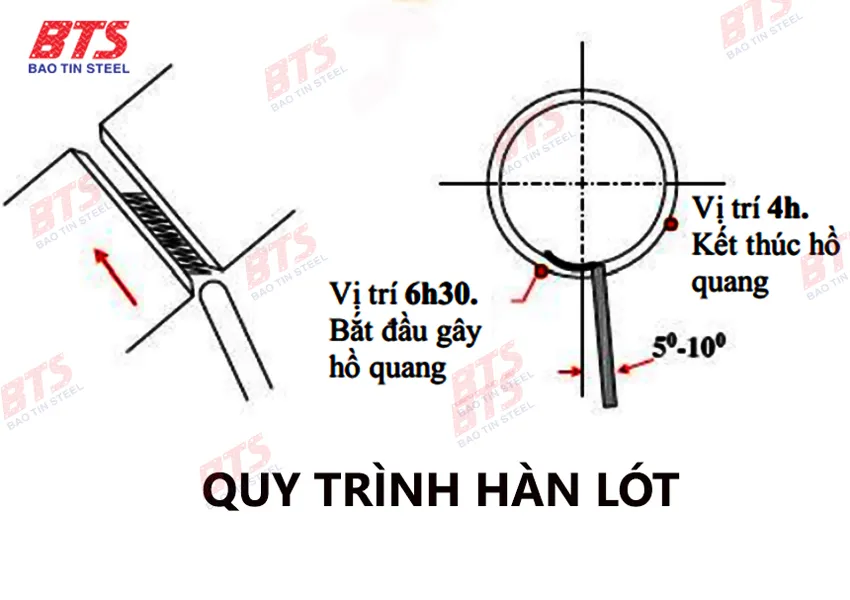

You can weld in two positions: 6:30 a.m. (if you are familiar with welding and have good technique) and 4:20 a.m. (if you are new to the job and your technique is not too good). With these two positions, we will have to lean a bit to weld.

Inside the weld groove, you weld the arc. At this time, it is necessary to weld evenly, ensuring the arc flows evenly and the arc distance is equal to 2 times the diameter of the welding rod. You can move the tip of the soldering iron slightly.

Always provide enough heat for the blunt edge. At the same time, move horizontally so that the metal and welding slag do not sag.

+ For lining welds

The compensation rod needs to be inserted properly and regularly. This is also a very important skill when welding steel pipes. The brazing process usually runs clockwise. To get a quality weld, you need to adjust the balance between the welding arm, the compensation rod position, and the welder’s position so that it is comfortable.

Note when performing steel pipe welding techniques

For the welding process to take place safely and for beautiful welds. You need to note a few points below:

- Clean and prepare the pipe surface before welding.

- Choose a welding rod or welding wire suitable for the type of steel.

- Adjust the welding current and voltage accordingly.

- Maintain proper welding rod or wire spacing.

- Use protective gas of the correct type and flow rate.

- Check the weld quality after welding.

Bao Tin Steel just shared basic and extremely simple steel pipe welding techniques. For welders who do not have much experience, hopefully, this will be useful information. Please save now and share with us your feelings!

Tiger Steel is a branch of Bao Tin Steel.

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ