Spiral-welded steel pipe is a type of welded steel pipe produced from cross-cut steel plates and joined using electric arc technology. This product is suitable for water supply and drainage system applications, mechanical engineering, shipbuilding, construction, etc. To better understand what spiral welded steel pipes are?, please join Bao Tin Steel to learn through the article below. This.

What is spiral welded steel pipe?

Spiral welded steel pipe (SSAW), also known as spiral submerged arc welded steel pipe or spiral steel pipe, is a type of steel pipe produced using arc technology with spiral welds running on the wall. tube.

Spiral-welded pipes are currently being produced in various sizes (DN200–DN4000). Suitable for use in large to extremely large-scale systems. This type of pipe is currently one of the indispensable products in many fields, specifically: construction, pipelines, shipbuilding,…

Currently, the Vietnamese market has not mastered this technology, but it needs to be improved. Domestic spiral submerged arc welding (SSAW) steel pipes have very high processing costs, so Bao Tin Steel accepts imports according to customer requirements. If you need to buy SSAW steel pipes, please contact 0932 059 176.

Why choose spiral welded pipes?

- The welds are evenly distributed into the tube in a spiral style, so every position on the tube has a relatively uniform force-bearing capacity.

- Designed with standard thickness, outstanding hardness, and good impact resistance,.

- It is applicable in many fluid environments, such as liquids, heat, compressed air, etc.

- High durability and a long service life can last up to several decades.

- Easy to handle and preserve in many ways, namely surface painting or galvanizing,…

The production process of spiral welded steel pipes

The image of the spiral welded steel pipe production process below will help you have a more general view:

- The steel billet is heated to a high temperature, then rolled into steel sheets.

- The steel plate is rolled and welded in a spiral shape using the electric arc welding method.

- The welding position is smoothed.

- The weld position is securely processed and checked carefully.

- Adjust pipe size according to standard specifications; shape pipe diameter

- Cut the tube into a predetermined size.

- Complete the product.

- Conduct quality inspections.

Steel pipes with different diameters can still be produced from the same type of rolled steel by adjusting the steel rolling angle.

Many tube sizes and lengths can be produced.

Check and give feedback on weld quality using an automatic ultrasonic weld inspection machine.

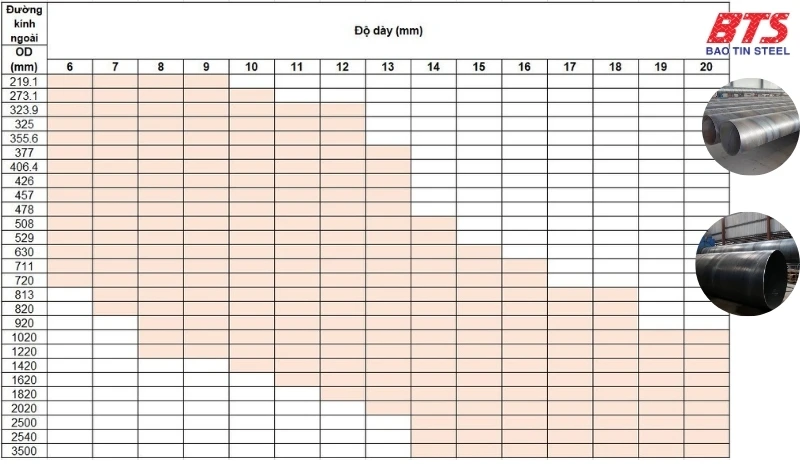

Specifications for spiral-welded steel pipes

- Size: 219.1mm – 4064mm

- Length: 6m-12m (can also be cut according to customer’s request)

- Pipe wall thickness: 3.2mm – 40mm

- Material: Steel

- Type: black welded steel pipe, galvanized

- Production method: Spiral welding by electric arc method

- Production standards: ASTM, API, BS, EN, JIS,…

- Steel grades: API 5L (GR A, GR B, X42, X46, X56, X60, X65, X70), ASTM (A252 GR 1, GR 2, GR 3). ASTM A53 (GR A, GR B, GR C, GR D). BS 4360 (Grade 43, Grade 50). EN S275 (S275JR, S355JRH, S355J2H).

- Application: widely used in industries: transportation, shipbuilding, construction, main pipes, pump pipes, pressure pipes, wind pipes, pile construction, and wastewater treatment engineering.

To help you better understand the specifications of spiral welded pipes, soon Bao Tin Steel will provide a general standard table on the size and thickness of spiral welded pipes. We invite you to refer to:

Standards for manufacturing spiral welded pipes

There are many standards applied to spiral-welded steel pipe products. According to research compiled by Bao Tin Steel, on the market today, the most popular spiral welded steel pipe production standards are:

API 5L standard

ASTM standards

BS standards

BS standards (British Standards) are standards for building and evaluating the quality of products or services in many fields. Specifically: civil, construction, industrial, electronics, health,… This is a standard issued by the British Royal National Standards Agency.

You may not know that in the field of manufacturing welded steel pipes, BS standards are regulated by the symbol BS 4360. Two commonly used steel grades in this standard are Grade 43 and Grade 50.

Quotation for spiral welded steel pipes

Spiral-welded pipes currently on the market come in many different sizes and thicknesses. Specifically in the specification table above.

A spiral welded pipe quote is an important tool to help you understand the cost and factors that affect the price of these types of steel. Spiral-welded steel pipes are widely used in construction, mechanical engineering, and other industries.

Currently on the market, the price of spiral welded steel pipes ranges from 19,000 to 22,000 VND per kg.

Many factors affect the price of welded steel pipes, such as size, thickness, price of steel raw materials, brand, quantity purchased, etc. Therefore, the price of spiral welded pipes can change continuously, depending on the time of purchase. For an accurate quote, please contact Bao Tin Steel directly.

Currently, on the market, there are many units distributing spiral welded pipe products. However, Bao Tin Steel Company Limited is still a trusted name in importing and supplying SSAW steel pipes to the Vietnamese market.

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ