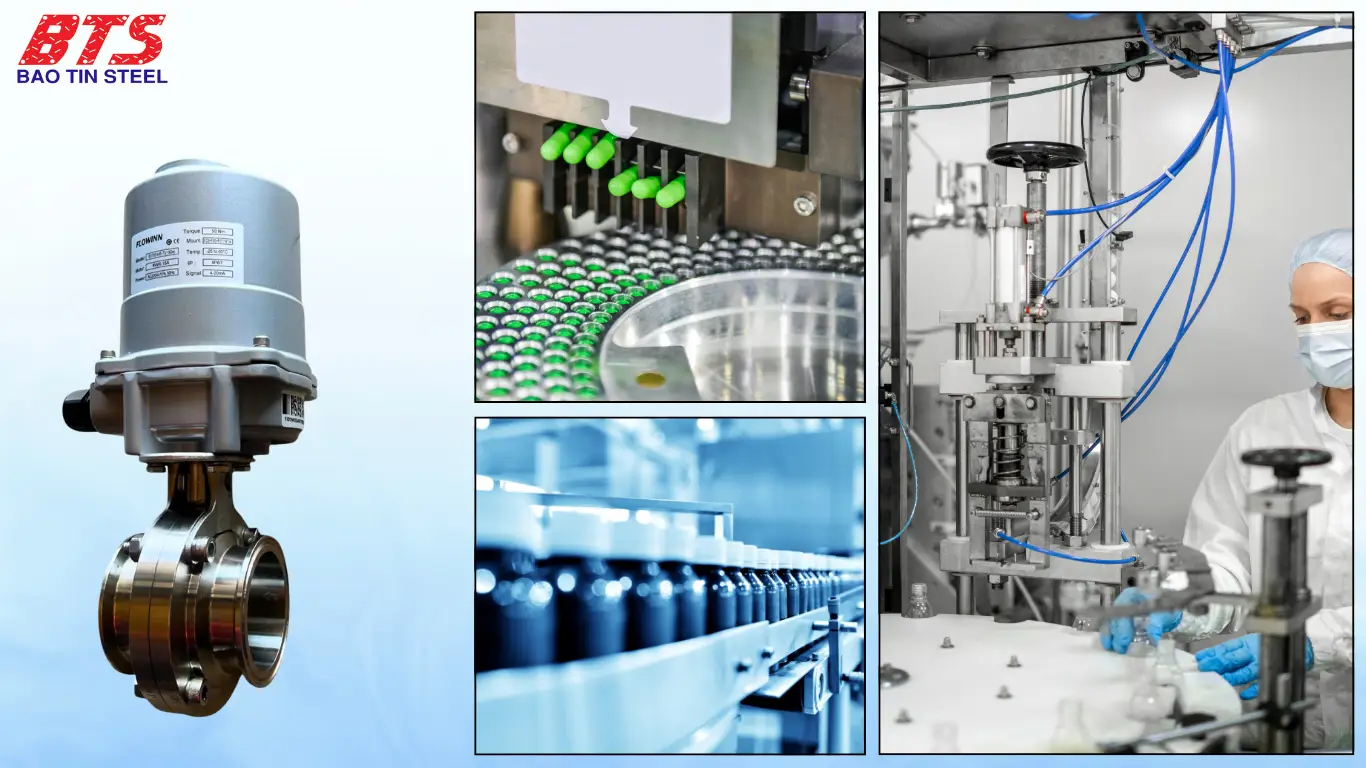

When operating a production system for food, pharmaceuticals, or beverages, you’ll find one non-negotiable rule: cleanliness is survival. And where absolute cleanliness is required, you need equipment designed to meet sanitary standards—and the sanitary butterfly valve is a crucial link in that chain.

Unlike standard industrial valves, a sanitary butterfly valve doesn’t just control flow; it also helps prevent bacterial buildup, resists cross-contamination, and ensures hygiene in every operation. From the mirror-polished 316L stainless steel surface to the easy-to-disassemble clamp connection mechanism, every detail is designed to maximise cleaning efficiency and shorten system sanitisation time (CIP/SIP).

In this article, Bao Tin Steel will explore with you:

- What is a sanitary butterfly valve?

- Special construction and FDA-compliant materials

- Classification by connection, control mechanism, and practical applications

- Tips for choosing the right valve for each system

- The latest price list & reputable brands in the market

If you’re looking for a device that is durable, sanitary, easy to install, and simple to maintain, then don’t overlook this type of valve. Let’s get started!

What is a sanitary butterfly valve? How is it different from a conventional industrial valve?

Sanitary butterfly valve—is a special type of industrial valve designed specifically for systems that require absolute hygiene, such as those in the food, pharmaceutical, cosmetics, and biotechnology industries.

In terms of operation, a sanitary butterfly valve is a type of butterfly valve that rotates a quarter turn (90°) to open, close, or regulate flow in a pipeline.

However, what makes this valve fundamentally different from standard industrial valves lies in its unique design philosophy:

The core difference of the microbiological butterfly valve

| Criteria | Industrial Butterfly Valve | Sanitary Butterfly Valve |

|---|---|---|

| Material | Cast iron, steel, regular stainless steel | 304/316L stainless steel – mirror polished |

| Surface | Rough, prone to residue buildup | Smooth, Ra ≤ 0.6 μm, resists bacterial adhesion |

| Sealing Gasket | Standard EPDM, NBR | FDA-approved EPDM, PTFE, Silicone |

| Connection | Wafer, flange | Clamp, weld, thread – easy to disassemble and clean |

| Standard | No special requirements | Meets 3A, FDA, EHEDG, ISO standards |

The Role of Sanitary Butterfly Valves in a System

The valve’s role is not just to control the flow; it also acts as a “sanitary barrier” to prevent bacteria from accumulating in the pipeline. This helps avoid cross-contamination between product batches and ensures the entire system can be cleaned in place (CIP) or sterilised in place (SIP) without complex disassembly.

That’s why you’ll find sanitary butterfly valves everywhere in:

- Factories producing milk, purified water, beer, and fruit juices

- Production lines for pharmaceuticals, cosmetics, and vaccines

- Aseptic packaging systems and high-level cleanroom areas

- Tanks, heat exchangers, and CIP piping

Detailed Structure of a Sanitary Butterfly Valve

Despite its compact design, the sanitary butterfly valve is a mechanical device fine-tuned to every detail to ensure it is clean, sealed, durable, and easy to maintain. This is why a small valve can significantly impact the quality of an entire product batch in a modern food or pharmaceutical production line.

Below are the main components that make up a standard sanitary butterfly valve:

Valve Body

- Material: Stainless steel 304 or, preferably, 316L—offering superior corrosion resistance and better resilience to CIP/SIP chemicals.

- Surface: Mirror polished—achieving a roughness of Ra ≤ 0.6 μm on the inside and Ra ≤ 1.6 μm on the outside.

- Function: It acts as the “shell” that protects the valve disc and gasket, and is in direct contact with the medium.

Stainless steel 316L is considered the “gold standard” in the production of milk, beer, and pharmaceuticals due to its excellent resistance to mild acids, steam, and harsh cleaning chemicals.

Disc

- Shape: Round, thin, and rotates 90° around the stem.

- Function: Opens, closes, and regulates the flow.

- Material: The same type of stainless steel as the valve body, with a polished surface.

The no-dead-leg design helps the liquid drain completely, leaving no residue behind—an extremely important factor for preventing cross-contamination.

Sealing Gasket

- Material: EPDM, Silicone, PTFE (Teflon), Viton—all of which must be FDA food-grade certified.

- Function: Creates a perfect seal between the valve disc and body, preventing any leakage or the suction of air back into the system.

Note: It’s essential to choose the correct type of gasket based on the medium and temperature. For example, use PTFE for harsh chemicals and Silicone for hot steam.

| Material | Temperature Resistance | Advantages |

|---|---|---|

| EPDM | -10°C to 135°C | Commonly used for water and steam. |

| Silicone | -48°C to 204°C | Very flexible, high-temperature resistance. |

| PTFE | -20°C to 200°C | Non-stick, extremely strong chemical resistance. |

| Viton | -10°C to 200°C | Used for chemicals and oils. |

Stem

- Material Stainless steel 304/316. It transfers force from the manual handle or actuator to the valve disc.

- Requirements: Must be rigid, durable, and rust-resistant, without creating crevices where residue can accumulate.

Actuator (Lever, Handwheel, Pneumatic, Electric)

- Lever Handle: Simple and easy to operate, with a position lock.

- Handwheel: Used for larger nominal diameter (DN) valves or gentle flow regulation.

- Pneumatic/Electric Actuator: Enables full automation and integration with SCADA/PLC systems.

Depending on the level of system automation, you can choose to operate the valve in either ON/OFF mode or linearly (for flow regulation).

Valve End Connections

- Most Common: Clamp (Tri-clamp) – Extremely quick to assemble and disassemble, no tools required.

- Other Types: Weld, thread, and flange – The choice depends on whether the system is permanent or needs frequent disassembly.

Operating Principle and Superior Technical Advantages

Operating Principle of a Sanitary Butterfly Valve

A sanitary butterfly valve is a quarter-turn valve. Its operating mechanism is very simple yet extremely effective:

- When you turn the handle or activate the actuator, the valve disc rotates around the stem at an angle from 0–90°.

- At 0° (fully closed): The valve disc is perpendicular to the flow, completely blocking the medium from passing through.

- At 90° (fully open): The disc is parallel to the flow, allowing the medium to pass through at its maximum flow rate.

- You can also hold the valve at intermediate angles to precisely regulate the flow, which is especially useful when using a modulating valve.

The key difference is that the disc, gasket, and valve body are designed without “dead spots.” This prevents the medium from accumulating and ensures absolute hygiene.

Superior Technical Advantages

A sanitary butterfly valve doesn’t just play a role in controlling flow; it also acts as a smart “sanitary barrier” that helps optimise production efficiency, save on operating costs, and protect the final product.

Optimal Sanitary Design – Meeting GMP, FDA, and 3A Standards

- The entire internal surface is mirror polished (Ra ≤ 0.6 μm), ensuring no residue buildup and no bacterial adhesion.

- Meets international standards like FDA, 3A, and EHEDG, which are especially important in the food, pharmaceutical, and beverage industries.

Easy to Install and Remove – Saves Cleaning Time

With a Clamp (Tri-clamp) connection, you can remove the valve in less than one minute without any specialised tools. This helps reduce system downtime for cleaning, maintenance, or gasket replacement.

Tight Seal, Flexible Operation

- Uses food-grade sealing gaskets (EPDM, PTFE, Viton, etc.) to provide an absolute seal against leakage, even with hot media, steam, or CIP chemicals.

- Can be quickly opened and closed, or operated linearly (when used with an electric or pneumatic actuator).

Easy Integration into Automation Systems

- Suitable for both ON/OFF and linear control.

- Simple integration with SCADA, PLC, pressure sensors, flow meters, etc. This increases production management efficiency and enables remote monitoring.

Compact and Space-Saving

Compared to sanitary ball or globe valves, butterfly valves are smaller, lighter, and easier to install. This makes them ideal for complex sanitary piping systems, including those installed vertically, on an incline, or in multi-story setups.

Classification of Sanitary Butterfly Valves on the Market

Although all are called sanitary butterfly valves, in reality, this product has many variations—differing in material, connection type, operating mechanism, and application. A clear classification will help you make the right choice for durability, easy cleaning, and long-term effectiveness.

Below are the most common classification criteria:

Classification by Stainless Steel Material

| Stainless Steel Type | Characteristics | Recommended Applications |

|---|---|---|

| 304 | Common, affordable, easy to fabricate | Clean water, general food products |

| 316L | High corrosion resistance, good resistance to CIP/SIP chemicals | Milk, pharmaceuticals, purified water, mild chemicals |

Bao Tin Steel always recommends using Stainless Steel 316L if the system involves cleaning with hot steam, cleaning chemicals, or requires adherence to 3-A and FDA standards.

Classification by Connection Type

| Connection Type | Advantages | Disadvantages | Suitable Applications |

|---|---|---|---|

| Clamp (Tri-clamp) | Quick to install, easy to remove, no tools required | Not suitable for high pressure | Systems with frequent cleaning, CIP/SIP |

| Weld (Butt-weld) | Absolute seal, very sturdy | Difficult to disassemble, requires a specialized welder | High-pressure, permanent systems |

| Threaded | Simple to install, low cost | Prone to leakage if installed incorrectly, size-limited | Small systems, infrequent disassembly |

| Wafer, Flange | Installed between flanges or with bolts | More bulky | Mixed-use industrial systems (not strictly sanitary) |

Classification by Operating Mechanism

| Mechanism | Advantages | Suggested Use |

|---|---|---|

| Lever Handle | Simple, compact, low cost | Small valves, infrequent opening/closing |

| Handwheel (Gearbox) | Easy to turn, more precise regulation | Large DN valves or when manual flow adjustment is needed |

| Pneumatic | Fast opening/closing speed, safe in flammable environments | Automation, large factories, SCADA/PLC systems |

| Electric | Remote control, high precision | Pharmaceutical – purified water lines, central monitoring |

Both pneumatic and electric valves can operate in either ON/OFF or linear mode, depending on the flow regulation requirements.

Classification by gasket material

| Gasket | Temperature Resistance (°C) | Chemical Resistance | Common Applications |

|---|---|---|---|

| EPDM | -10 to 135 | Medium | Water, beverages, mild CIP processes |

| Silicone | -48 to 204 | Medium | High-temperature food applications |

| PTFE (Teflon) | -20 to 200 | Very High | Pharmaceuticals, chemicals |

| Viton | -10 to 200 | High (oils, solvents) | Pharmaceuticals, sterilising chemicals |

PTFE or Viton gaskets should be used when the medium is corrosive or the system uses CIP/SIP chemicals frequently.

Practical application of sanitary butterfly valves in production

Thanks to their optimal hygienic design and stable operation, sanitary butterfly valves are not just a technical component—they are the “gatekeepers” that ensure product purity and safety in many important production lines.

Below are the most common applications that Thép Bảo Tín has encountered during real-world consulting and equipment supply:

Food & Beverage Processing Industry

Based on your description, sanitary butterfly valves are an indispensable component in the following systems:

- Dairy Production: Including the manufacturing of milk, yoghurt, and UHT (Ultra-High Temperature) pasteurized milk.

- Beverage Processing: Such as in the production of fruit juice, purified water, and carbonated soft drinks.

- Brewing and Beverage Lines: Specifically in the production of beer, wine, and other beverages.

Valves are typically installed at the following points: tank inlets, CIP lines, product distribution lines, packaging areas, and product recovery systems.

Priorities:

- Material: 316L stainless steel

- Connection: Clamp or weld

- Control: Manual or pneumatic, depending on the stage

- Gasket: FDA-compliant EPDM, PTFE

Pharmaceutical and Cosmetics Industry

In the pharmaceutical industry—where strict cleanliness, sterility, and compliance with GMP, WHO, and FDA standards are required—sanitary butterfly valves play a crucial role:

- Controlling the flow of formulation liquids, excipients, solvents, and RO (Reverse Osmosis) water.

- Integrating into SIP (Sterilisation-in-Place) and CIP (Clean-in-Place) systems.

- Distributing ingredients through various modules like tanks, mixers, and formulation vessels.

The cosmetics industry (including products like lotions, serums, shampoos, and hand sanitisers) also requires systems that are clean, easy to sanitise, and prevent products from mixing between batches.

Recommendations:

- Stainless steel 316L + surface Ra ≤ 0.6μm

- Viton or PTFE gasket

- Electric or pneumatic control valve (precision regulation)

- Clip connection for easy disassembly, testing, and replacement

Biotechnology and the clean chemicals industry

In microbial culture environments, enzymatic reactions, or specialised chemical production, a sanitary butterfly valve helps:

- Regulate the flow of culture media and reaction solutions.

- Connect to fermenters, sterilisation systems (CIP/SIP), and storage tanks.

- Prevent cross-contamination and the accumulation of biological residue (biofilm) in the pipeline.

This is where sanitary design is not only for cleanliness, but also to prevent variation in the output product.

RO pure water & clean steam system

In pharmaceutical, functional food, cosmetic, and bottled water plants, sanitary butterfly valves are typically installed at:

- The outlet of RO (reverse osmosis) filtration systems

- The inlet of water storage tanks

- The outlet of clean steam distribution pipelines (for sterilisation)

You should choose a valve that can withstand high-temperature steam, made of 316L stainless steel with Silicone or PTFE gaskets to prevent creep and deformation.

In addition to the above applications, sanitary butterfly valves are also used in systems that supply liquid solutions, hand sanitisers, or regulate sterile air in operating rooms and hospital pharmaceutical preparation rooms.

The latest updated price list of sanitary butterfly valves

The current market price for sanitary butterfly valves varies significantly depending on:

- Material (304 or 316L stainless steel)

- Connection type (clamp, weld, threaded)

- Operating mechanism (manual lever, pneumatic, electric)

- Brand and accompanying certifications (FDA, 3A, EHEDG, CO-CQ)

Below is a reference price list compiled by Thép Bảo Tín from common brands such as BTL, INOXPA, AUT, CSE, and Wonil, applicable to the Vietnamese market as of June 2025.

Price list of sanitary butterfly valves with lever handle – Clamp connection (Stainless Steel 316L)

| Size (DN) | Price (VNĐ) | Notes |

|---|---|---|

| DN25 (1″) | 690,000 – 950,000 | Stainless steel lever handle, 3A clamp |

| DN32 (1.25″) | 780,000 – 1,050,000 | 316L stainless steel, EPDM gasket |

| DN40 (1.5″) | 870,000 – 1,250,000 | Common in the dairy and water industries |

| DN50 (2″) | 1,050,000 – 1,450,000 | Commonly used in CIP systems |

| DN63.5 (2.5″) | 1,400,000 – 1,850,000 | Typically conforms to SMS standards |

| DN76.1 (3″) | 1,750,000 – 2,250,000 | Custom orders required |

| DN100 (4″) | 2,300,000 – 3,000,000 | Installed in tanks, main pipelines |

The price may vary depending on the gasket material (PTFE/Viton is more expensive than EPDM), the type of handle (pull-handle or fixed), and the connection standard (DIN, SMS, ISO, etc.).

Pneumatic-controlled sanitary butterfly valve price

| Valve Type | Reference Price | Description |

|---|---|---|

| Pneumatic ON/OFF (DN40) | 3,800,000 – 5,500,000 VND | Includes valve + pneumatic actuator + basic positioner |

| Linear Pneumatic (DN40–DN50) | 6,000,000 – 8,000,000 VND | Features 4-20mA control signal and angle sensor |

| With Monitoring Switches | 1,200,000 – 1,600,000 VND | Remotely monitors open/closed status |

Electric control sanitary butterfly valve price

| Size (DN) | Reference Price (VND) | Status |

|---|---|---|

| DN25 – DN50 | 4,200,000 – 6,500,000 | In stock from brands like AUT, CSE |

| DN65 – DN100 | 7,000,000 – 10,500,000 | Requires 5–7 days for ordering |

=> You might be interested in: The latest 2025 price list for butterfly valves.

Instructions for proper installation and cleaning of sanitary butterfly valves

Sanitary butterfly valves have a very specific construction and material makeup, prioritising hygiene, sealing, and durability in clean environments. However, if you install or clean them incorrectly, all of the valve’s advantages can turn into risks, leading to leaks, contamination, gasket failure, or even damage to the entire system.

Here is a step-by-step guide to help you ensure your valve operates correctly and lasts a long time:

Instructions for installing sanitary butterfly valves

Preparation before installation:

- Thoroughly clean the flange or clamp connection, paying special attention to removing any chemical residue or metal particles.

- Inspect the gasket’s condition: it should not be cracked or have flattened edges.

- Ensure the valve is in a partially open position (~15–30°) to prevent the disc from getting stuck during installation.

Correct Installation Procedures:

- Align concentrically: Ensure the valve and pipeline are perfectly aligned to prevent misalignment, which can warp the disc or tear the gasket.

- Install in the correct direction: If the valve has a flow direction symbol (FLOW), install it according to the indicated direction for optimal performance.

- For clamp connections: Place the gasket correctly in the groove, then tighten the clamp evenly on both sides. Do not overtighten, as this can deform the gasket or valve body.

- For weld connections: Use a specialised stainless steel welding torch to ensure a smooth and sealed weld. Make sure there are no gaps or crevices in the weld seam.

- Post-installation check: After installation, open and close the valve a few times to check for any sticking. Also, run a test flow to check for any leaks at the connections.

Never use twisting force, prying, or hard tools on the valve disc, as this can scratch the surface or tear the sanitary gasket.

Sanitary butterfly valve cleaning instructions (CIP/SIP)

In a microbial system, sanitation is just as critical as production. Valves must always be clean—free of milk residue, starch, yeast, chemicals, or bacteria.

Basic Cleaning Procedure:

- Initial Step: Flush the pipeline to remove any residual material before cleaning.

- CIP (Cleaning In Place): The process involves a sequential rinse, hot water wash, chemical wash, and a final cold water rinse.

- SIP (Sterilise In Place): Introduce clean steam at a temperature of ≥121°C for 15–30 minutes (depending on GMP procedures).

If the valve is disassembled:

- Use warm water and a neutral cleaning solution.

- Do not use sharp or abrasive objects to scrub the stainless steel or gasket.

- Dry the parts and inspect the gasket before reassembly.

Conclusion

A sanitary butterfly valve is more than just a flow control device—it is an integral part of ensuring hygiene, purity, and product quality in the food, beverage, pharmaceutical, cosmetic, and purified water industries.

When you choose the right materials (316L stainless steel, PTFE gaskets, etc.), the right connection type (clamp, weld, etc.), and the right operating mechanism (manual, pneumatic, electric), and you ensure proper installation, operation, and cleaning procedures, you are:

- Extend your system’s lifespan

- Minimise downtime and maintenance costs

- Ensure products meet quality and regulatory standards

If you’re looking for the right sanitary butterfly valve for your plant, let Thép Bảo Tín assist you with:

- A full range of manual, pneumatic, and electric valves in 304/316L stainless steel

- Available connections: Clamp, weld, and threaded—with DIN, SMS, and 3A standards

- Complete certifications: CO – CQ – FDA – 3A – Test reports

- Fast quotes and nationwide delivery

- Free technical consultation

Zalo/HolineTechnical: 0932 059 176 – Email: bts@thepbaotin.com

Tiger Steel is a subsidiary of Bao Tin Steel.

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ