Are you looking for a compact, easy-to-operate, cost-effective industrial valve suitable for water systems, chemicals, or fire protection systems? If so, the manual lever butterfly valve could be the solution you’re looking for.

With a simple design and operation requiring just a 90-degree lever movement to open/close, this valve is widely used in many factories, construction projects, and technical systems. However, not everyone understands when to use a manual lever valve, its pros and cons, and how it differs from handwheel valves or other types of valves available in the market.

In this article, Bao Tin Steel will help you explore the manual lever butterfly valve in detail: from its structure, working principle, practical applications, to the latest price update for 2025 and guidance on selecting the right one based on your usage needs

What is a manual lever butterfly valve?

A manual lever butterfly valve is a type of industrial butterfly valve used to open/close or regulate the flow in pipeline systems. The most noticeable feature of this valve is the lever control located above the valve body – simply rotating the lever 90 degrees allows you to switch between the open and closed positions, or vice versa.

Unlike more complex valve types such as ball valves or globe valves, the manual lever butterfly valve has a compact and lightweight design, easy operation, and quick installation, making it particularly suitable for systems with small to medium pipelines (ranging from DN40 to DN200).

The valve is directly installed between two flanges on the pipeline (wafer or lug type), allowing control of water, air, or liquid flow. When the valve disc is parallel to the flow, the valve is fully open. When the disc rotates perpendicular to the flow, the valve closes – blocking the fluid flow.

Due to its quick operation and the lack of need for electricity or compressed air, this valve is highly popular in water treatment systems, fire protection, food processing, light chemicals, and civil engineering applications

Common valve body materials:

- Epoxy-coated cast iron

- Stainless steel 304 / 316

- PVC / uPVC plastic

Structure and Operating Principle of the Manual Lever Butterfly Valve

Although it has a compact and simple design, the manual lever butterfly valve is one of the valve types that has been highly optimised in terms of engineering, operational efficiency, and cost-effectiveness.

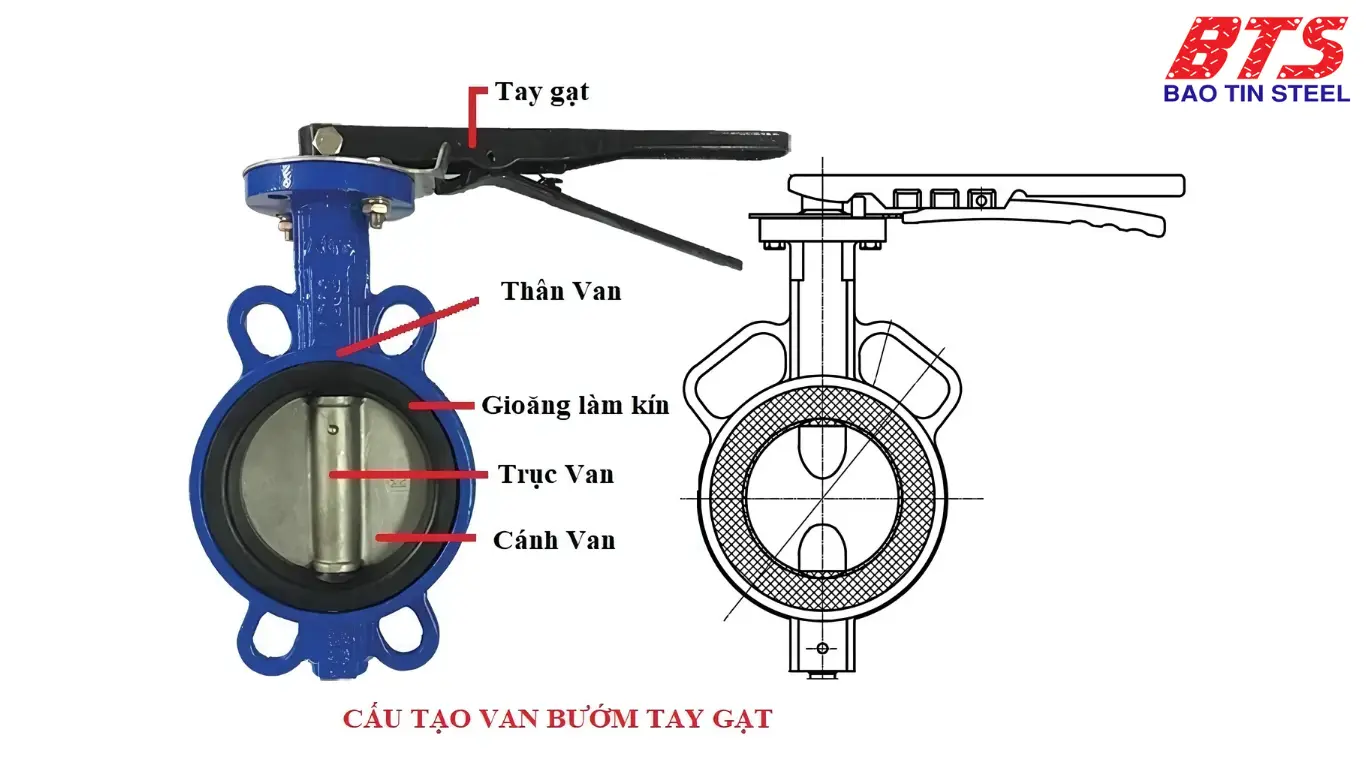

Basic Structure:

- Valve Body: The main frame, usually made of cast iron, stainless steel, or PVC plastic, which bears the pressure and connects to the pipe.

- Valve Disc: Round, like a butterfly wing, positioned in the pipeline – it opens/closes the flow when it rotates.

- Sealing Gasket: Made of EPDM, NBR, or PTFE (Teflon) – ensures the valve is completely sealed when closed.

- Valve Stem: Connects the lever to the disc, transmitting the force to open/close the valve. It’s usually made of stainless steel.

- Lever: The manual operation part, rotating 90° to open/close. It has fixed positioning stops for the opening angle.

Some valves also have a locking mechanism to prevent the valve from unintentionally changing its state due to vibrations or impact.

Operating Principle

The manual lever butterfly valve operates based on the mechanism of rotating the valve disc 90 degrees (1/4 turn) around the vertical axis of the valve body.

- Valve Open: When the lever rotates the disc to a position parallel to the flow.

- Valve Closed: When the lever rotates the disc to a position perpendicular to the flow.

- Partially Open (Regulation): When the lever is held at a fixed angle (30°, 45°, 60°, etc.).

Important Note: Avoid maintaining the partially open state between 15° and 75° for extended periods. At this angle, the valve disc experiences significant friction and turbulence, which can easily damage the gasket, cause valve vibrations, and reduce its lifespan.

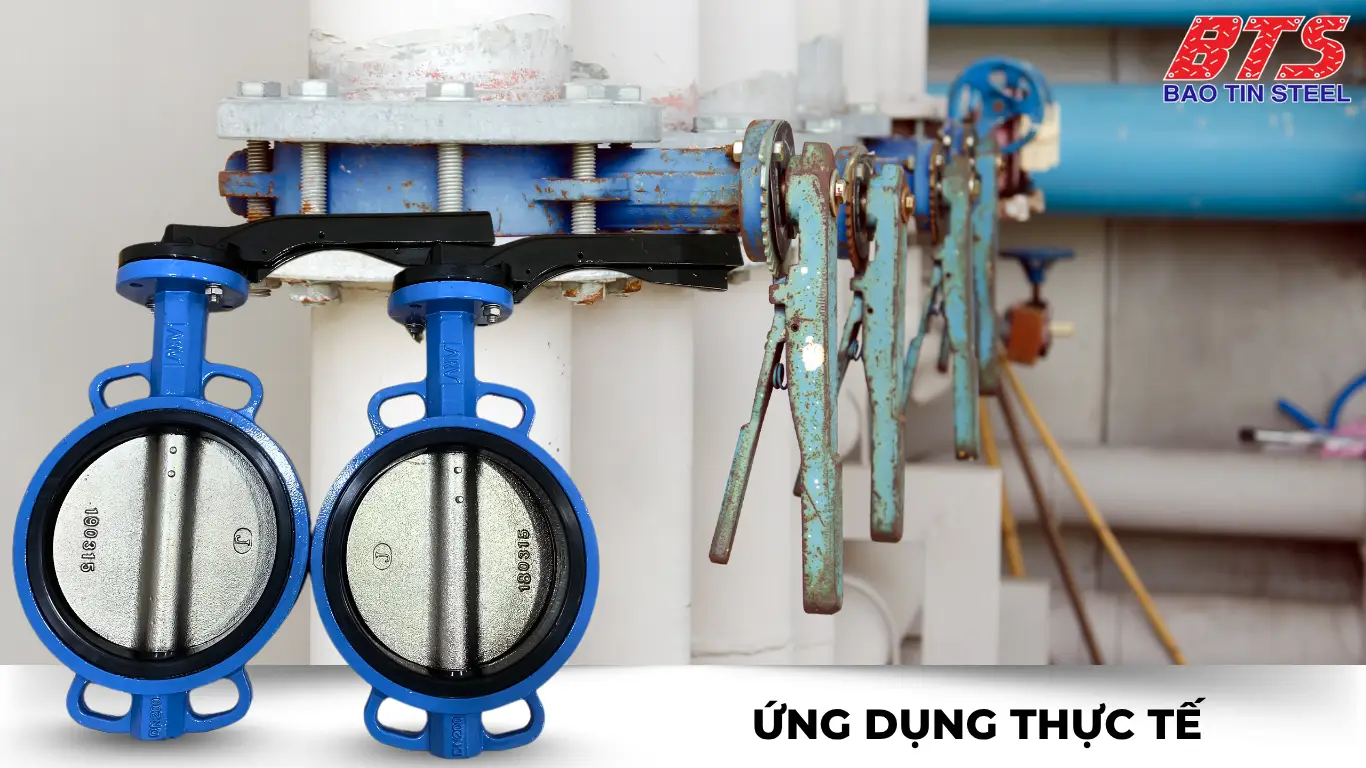

Practical Applications of the Manual Lever Butterfly Valve

Due to its compact design, quick operation, cost-effectiveness, and flexible installation, the manual lever butterfly valve has become one of the most commonly used valves in both domestic and industrial applications.

Depending on the material (cast iron, stainless steel, plastic), the valve can be used for various types of fluids such as clean water, wastewater, light chemicals, compressed air, and even food and beverages.

Here are some common applications:

- Water supply and drainage systems

- Fire protection systems (PCCC)

- Used in water, soft drinks, milk, beer, and alcohol production lines

- Wastewater treatment systems, transportation of light acids, alkalis, salts, etc.

- Low-pressure compressed air systems – HVAC

Whether it’s a domestic water system, an industrial plant, or light chemical processing, the manual lever butterfly valve is always an economical, flexible, and reliable choice for various operating conditions.

Common Types of Manual Lever Butterfly Valves Today

Manual lever butterfly valves can be classified based on various criteria such as valve body material, nominal size (DN), and connection type with the pipeline.

Classification by Material

| Valve Type | Key Features | Common Applications |

|---|---|---|

| Cast Iron Manual Lever Butterfly Valve | Affordable, high-strength, epoxy coating to resist rust | Water systems, fire protection, HVAC, and civil engineering projects |

| Stainless Steel 304/316 Manual Lever Butterfly Valve | Excellent corrosion resistance, suitable for mild acid/alkali environments, good heat resistance | Food industry, chemicals, brine, pharmaceuticals |

| PVC/uPVC Manual Lever Butterfly Valve | Lightweight, resistant to corrosive chemicals, rust-proof, cost-effective | Wastewater treatment, light chemical transport, low-corrosion systems |

Classification by Size

Manual lever butterfly valves are commonly produced in the following sizes:

- DN40 (ø49) → Small valves for domestic pipelines

- DN50 – DN150 → Commonly used in industrial applications

- DN200 – DN300 → Still use lever operation for low-pressure environments

For sizes DN250 and above, it is recommended to consider switching to a handwheel valve for easier operation, as the larger torque will make the lever harder to operate.

Classification by Connection Standards

| Connection Type | Key Features | Supported Standards |

|---|---|---|

| Wafer (Wafer type) | Sandwiched between two flanges with bolts, compact, easy to replace, and most common | JIS, DIN, ANSI, BS |

| Lug (Lug type) | Has threaded holes to connect independently to each flange – easy to remove one side without affecting the system | DIN, ANSI |

| Flanged | Flanges are cast directly onto the valve – high sealing, used for high-pressure or hazardous environments | ASME, JIS |

The wafer connection is suitable for most projects, while the lug or flanged connections are more suitable for systems that require flexible disassembly or need to withstand high pressure

Comparison between Manual Lever Butterfly Valve and Handwheel Butterfly Valve

Both the manual lever butterfly valve and the handwheel butterfly valve belong to the category of manually operated valves, widely used in water supply systems, fire protection, HVAC, wastewater treatment, and various industries. However, each type has its advantages and limitations, making it suitable for different installation conditions and system scales.

Below is a detailed comparison table between these two valve types

Comparison Table between Manual Lever Butterfly Valve and Handwheel Butterfly Valve

| Criteria | Manual Lever Butterfly Valve | Handwheel Butterfly Valve |

|---|---|---|

| Control Mechanism | 90° lever turn directly | Handwheel (steering wheel) + gear reduction box |

| Applicable Size | DN40 – DN250 (up to DN300) | DN100 and above, commonly DN150 – DN600 |

| Opening/Closing Speed | Very fast (1 lever operation) | Slower (requires multiple turns of the handwheel) |

| Operating Force | Light for small valves requires more effort for large sizes | Lighter operation thanks to the gear assistance |

| Regulation Precision | Average (limited to fixed positions) | High (can adjust the opening smoothly and precisely) |

| Upgrade Flexibility | Difficult to integrate with motor control | Easy to integrate with electric or pneumatic control systems |

| Installation Space | Compact, suitable for tight spaces | Requires more space to turn the handwheel |

| Cost | 10–20% cheaper | Higher cost due to more complex design |

Which Type to Choose?

Choose the manual lever butterfly valve if:

- You need quick opening/closing

- The pipeline is small to medium (≤ DN200)

- Operation is not very frequent

- The installation space is tight

- You prioritize a lower cost, easy replacement

Choose the Handwheel Butterfly Valve if:

- The pipeline is large (≥ DN150), with high pressure

- You need precise flow regulation

- Frequent operation or continuous use is required

- You want to upgrade to an automatic control valve

- You prioritize mechanical durability and ease of operation

Latest Manual Lever Butterfly Valve Prices [June 2025]

The price of a manual lever butterfly valve depends on several factors such as size (DN), material (cast iron, stainless steel, plastic), brand, connection standards, and purchase quantity. Below is a reference price list for June 2025, applicable to commonly available products in the market

| Size (DN) | Cast Iron Lever Valve (VND) | Stainless Steel 304 Lever Valve (VND) | PVC Lever Valve (VND) |

|---|---|---|---|

| DN40 | 250,000 – 310,000 | 750,000 – 950,000 | 150,000 – 200,000 |

| DN50 | 280,000 – 340,000 | 800,000 – 1,050,000 | 180,000 – 230,000 |

| DN80 | 390,000 – 490,000 | 1,200,000 – 1,400,000 | 280,000 – 350,000 |

| DN100 | 450,000 – 580,000 | 1,400,000 – 1,700,000 | 320,000 – 400,000 |

| DN150 | 750,000 – 950,000 | 2,000,000 – 2,400,000 | 450,000 – 600,000 |

| DN200 | 1,200,000 – 1,400,000 | 2,800,000 – 3,200,000 | 650,000 – 850,000 |

| DN250 | 1,750,000 – 2,200,000 | Contact for pricing | Contact for pricing |

| DN300 | 2,500,000 – 3,000,000 | Contact for pricing | Contact for pricing |

Note: This is a reference price list and may vary by ±10% depending on the brand (ARV, AUT, Wonil, Hershey…), the order time, and purchase quantity

=> See More: Latest Butterfly Valve Price List 2025 – Updated by Size, Material & Brand

If you are working on a construction project or need a large quantity, please contact directly via Hotline 0932 059 176 to receive discounted prices based on product type, size, and shipping conditions.

Important Considerations When Buying a Manual Lever Butterfly Valve

Although the manual lever butterfly valve is easy to use and commonly found in many technical systems, choosing the wrong size, material, or connection type can lead to leakage, valve jams, or reduced equipment lifespan. Below are some important considerations you should take into account before placing an order

Determine the Working Environment

| Environment | Recommended Material |

|---|---|

| Clean water, cold water | Cast iron, stainless steel 304 |

| Saltwater, light chemicals | Stainless steel 316, PVC/uPVC plastic |

| Acid, alkali, and highly corrosive agents | PVC, uPVC plastic, or valves with PTFE (Teflon) seals |

| Hot water (above 80°C) | Stainless steel 316 or cast iron with heat-resistant seals |

Always ensure that the sealing gasket and valve body are compatible with the fluid to prevent leakage, rapid wear, or chemical reactions.

Check the Working Pressure of the System

- Manual lever butterfly valves typically have pressure ratings of PN10 or PN16.

- If the system pressure is greater than 16 bar, it’s recommended to switch to a handwheel valve or a valve controlled by a gearbox.

- Avoid selecting a valve that is too “weak” for high-pressure systems, as it can cause seal failure or shaft bending.

Choose the Appropriate Connection Type for the Pipeline

| Connection Type | Advantages | Suitable for |

|---|---|---|

| Wafer | Compact, installed between two flanges, cost-effective | Residential, general construction projects |

| Lug | Separate threads for each flange, easy to install and remove on each side | Systems requiring frequent maintenance |

| Flanged | Perfect seal, durable, good for high-pressure | Heavy industry, high-pressure systems |

Considerations for Size and Installation Space:

- Narrow space → Prioritise manual lever (DN ≤ 200).

- Wide space, large pipes, and high torque → Handwheel is a better option.

- Check the actual pipeline to ensure that the valve disc does not interfere when rotating.

Don’t choose a valve just because it’s cheap – select the right valve for the right system. A good decision from the start will save you a lot of time and replacement costs later.

Where to Buy Reliable and Affordable Manual Lever Butterfly Valves

With the increasing demand for manual lever butterfly valves in water supply systems, firefighting (PCCC), chemicals, and wastewater treatment, choosing a reliable supplier is crucial to ensure product quality, compliance with technical standards, and reasonable prices.

At Bao Tin Steel, we specialize in providing manual lever butterfly valves across a wide range of product lines:

- Cast iron manual lever valves DN40 – DN300

- 304, 316 stainless steel manual lever valves for food and chemical industries

- PVC/uPVC manual lever valves for corrosive systems

- Connection types: wafer, lug, flanged – compatible with JIS, DIN, ANSI standards

Bao Tin steel’s Commitments:

- 100% genuine products, complete CO/CQ, VAT invoices

- Competitive prices – attractive discounts for bulk orders

- Fast nationwide delivery

- Free technical consultation for various systems: water, chemicals, pneumatics, firefighting (PCCC), etc.

- Official warranty up to 12 months

Contact us now for consultation and to receive the best price quote today!

HOTLINE: 0932 059 176 – EMAIL: kinhdoanh@thepbaotin.com

Conclusion

As you can see, the manual lever butterfly valve is a simple yet highly effective solution for water supply systems, wastewater treatment, firefighting (PCCC), HVAC, or light chemical transport. However, to select the right valve, material, and connection standard, you need a supplier with technical expertise, available stock, and dedicated consultation.

Bao Tin Steel – A trusted partner of hundreds of engineers, contractors, and businesses nationwide.

Tiger Steel is a subsidiary of Bao tin Steel.

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ