If you are looking for a high-quality, cost-effective, and easy-to-use butterfly valve for projects in Vietnam, then ShinYi Butterfly Valves are definitely a brand to consider.

Shin Yi Valves Corporation is a Taiwanese brand established in Vietnam in 2005, with its factory located in Dong Nai Province. By combining foreign technology with a deep understanding of local requirements, Shin Yi has quickly become one of the leading industrial valve manufacturers in Vietnam.

Among its product lines, Shin Yi Butterfly Valves are the flagship product, trusted by engineers, contractors, and investors. These valves are designed and manufactured in accordance with international standards, including BS 5155, API 609, JIS B2220, and ISO 5752, ensuring high tightness, smooth operation, long-lasting durability, and excellent adaptability to water, steam, air, and light chemical environments.

Currently, Shin Yi offers a variety of butterfly valve lines, including:

- Lever & Gear Handwheel Butterfly Valves – WB/FB series

- Electric Actuated Butterfly Valves – EOM series

Available in sizes from DN50 to DN1200, with ductile iron bodies, stainless steel discs, and EPDM or PTFE seats.

The biggest advantage of Shin Yi Butterfly Valves is their perfect balance of quality, price, and practical applicability. Whether you are working on a small civil project or a large industrial plant, these valves can effectively meet both technical requirements and budget constraints.

Popular Shin Yi Butterfly Valve Lines

Shin Yi offers a variety of butterfly valve designs, suitable for applications ranging from simple manual operation to fully automated systems. The following are the most popular butterfly valve lines from this brand:

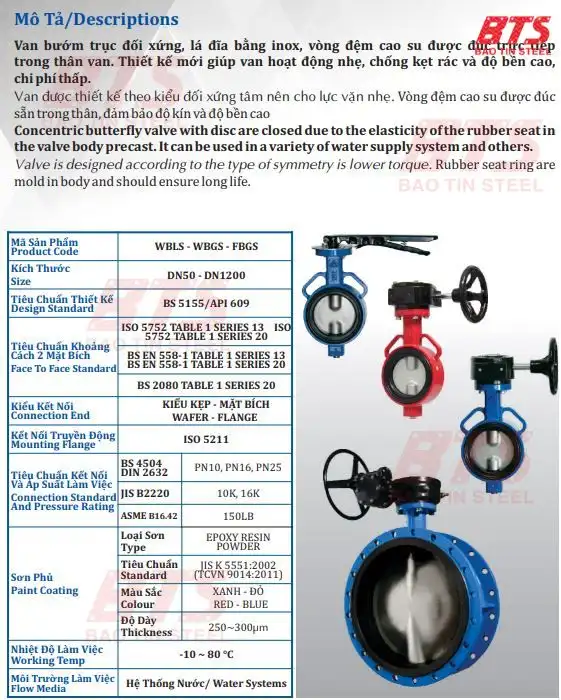

Symmetric Shaft Butterfly Valve – WB/FB Series

This is a basic butterfly valve operated manually by lever or gear handwheel, suitable for most standard water and air systems. The valve body is flat and thin, featuring ears (or grooves) on the top and bottom for alignment and clamping between two pipe flanges. These ears are reinforced for durability.

The body surface is coated with epoxy paint for corrosion protection. Inside the body, a black sealing gasket surrounds the valve disc. The valve disc itself has the characteristic shiny silver colour of stainless steel.

Key Features:

- Symmetrical shaft design allows smooth opening and closing with low torque, making it easy to operate.

- EPDM/NBR gasket moulded into the body – provides high tightness and prevents debris jamming.

- Body material: Ductile iron FCD – ASTM A536

- Valve disc: Stainless steel CF8/CF8M, suitable for mildly corrosive environments.

- Sizes: DN50 – DN1200

- Connection types: Wafer or flanged, compliant with BS/JIS/ANSI standards

Suitable Applications: Water supply and drainage systems, wastewater treatment, fire protection (PCCC), HVAC, and both civil and industrial projects.

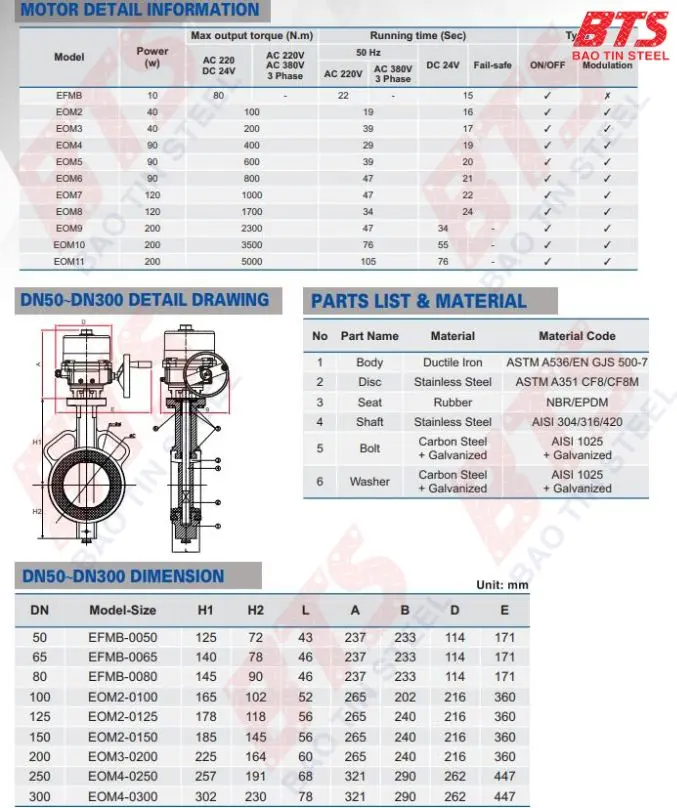

Electric Actuated Butterfly Valve – EOM Series

This valve series uses an electric actuator to open and close the valve remotely or automatically through a central control system. The valve is designed as a single integrated unit combining the valve body and the electric actuator on top. The valve body is flat and thin, characteristic of butterfly valves, coated with red or blue epoxy paint for corrosion protection and easy identification.

The valve features two pairs of lugs (a total of 4, two on top and two on bottom) with round holes for alignment and clamping between two pipe flanges using through bolts, or flange holes on the sides (for flanged connections). The valve disc is made of stainless steel with its characteristic shiny silver colour.

The control box is a black cylindrical or rectangular unit containing the electric motor, gearbox, and control circuits. It also includes a manual handwheel with spokes and an outer rim with grip, allowing manual operation during emergencies, power outages, or initial setup.

Key Features:

- Operates on AC 220V, AC 380V, or DC 24V

- Supports ON/OFF or Modulating control, with optional Fail-safe function

- Size range: DN50 – DN600

- Torque up to 5000 Nm – ensures stable operation and smooth opening/closing

- Materials: Stainless steel disc, stainless steel shaft, EPDM/NBR or PTFE seat

- Premium epoxy coating – provides excellent corrosion resistance

Suitable Applications: Smart buildings, factories with SCADA/BMS systems, water pumping stations, and automated production lines.

Connection & Operation Options

Shin Yi supports a full range of connection standards and operating methods:

Connection types: Wafer, Lug, Flanged

Operating methods:

- Lever handle

- Gear handwheel (worm gear)

- Electric actuator

- Pneumatic actuator

Technical Specifications of Shin Yi Butterfly Valves

Shin Yi Butterfly Valves are designed according to international standards, offering a wide range of sizes, materials, and operating methods, suitable for technical requirements from civil to industrial applications. The following is a summary of the key specifications by product series:

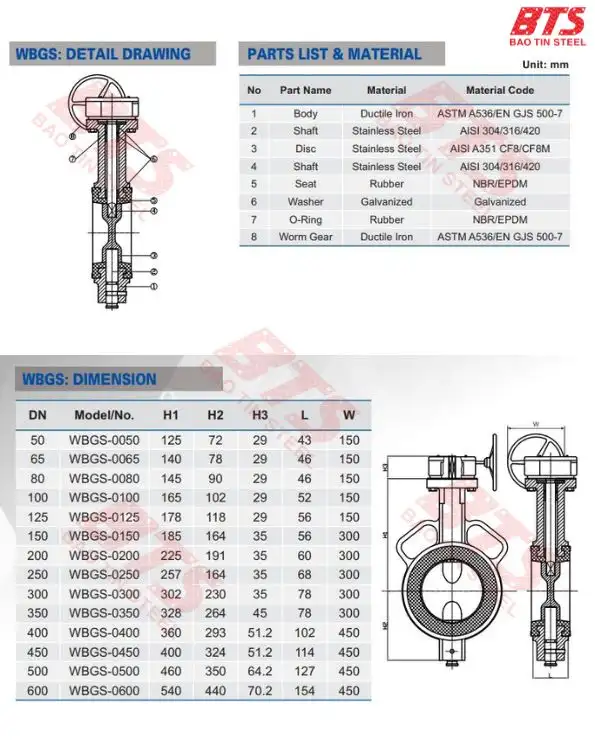

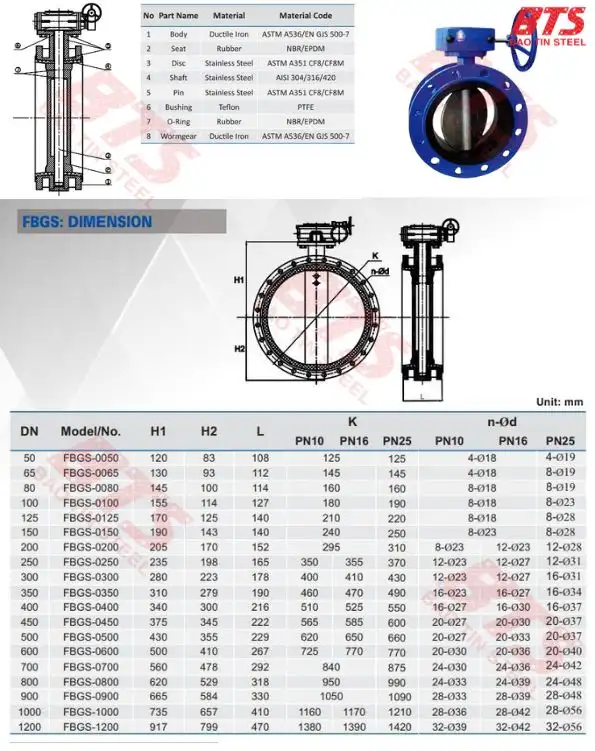

WB/FB Series – Symmetric Shaft Butterfly Valve (Concentric)

EOM Series – Electric Actuated Butterfly Valve (Motorised)

Outstanding Advantages of Shin Yi Butterfly Valves

Shin Yi Butterfly Valves are highly regarded not only for their technical quality but also for their operational efficiency, flexible applicability, and reasonable cost. The following are the key advantages that make this valve line a trusted choice for many engineers and contractors:

- The Symmetric Shaft Butterfly Valve (WB/FB Series) is designed to reduce torque, allowing the valve disc to open and close smoothly, prevent debris jamming, and minimise seat wear.

- The entire valve features a ductile iron FCD body, stainless steel CF8/CF8M disc, and stainless steel 304/316 shaft, combined with EPDM/NBR or PTFE seats, making it suitable for wet, mildly corrosive, or light chemical environments.

- Shin Yi offers a full range from lever-operated and gear handwheel valves to electric actuated valves (EOM Series), with multiple sizes, connection types, and material options.

- All valves are designed according to BS, ISO, JIS, DIN, and ANSI standards, ensuring easy installation into existing pipelines without major system modifications.

- Standard wafer, lug, and flanged connections allow quick assembly and disassembly. The electric actuator complies with ISO 5211, making it easy to upgrade to fully automated operation.

- Compared to imported brands from Korea or Europe, Shin Yi Butterfly Valves are more cost-effective while still meeting technical standards, suitable for both civil works and large-scale industrial projects.

It can be said that Shin Yi Butterfly Valves are the ideal combination of quality, performance, and cost.

Practical Applications in Projects

Shin Yi Butterfly Valves are designed to meet a wide range of technical requirements in water supply and drainage, fire protection (PCCC), industrial, and infrastructure systems. With multiple options for materials, control methods, and connections, these valves can be easily integrated into both new installations and existing systems. Common applications include:

- Water treatment plants – clean water and wastewater systems

- Fire protection systems (PCCC) – main pipe runs, shut-off valves, and sprinkler clusters

- Industrial plants and export processing zones – cooling water, compressed air, and industrial liquids

- Central air-conditioning and HVAC systems – regulating chilled water and airflow

- Food, pharmaceutical, and light chemical industries

Depending on the scale of the project and operating environment, you can easily select a Shin Yi Butterfly Valve with the most suitable material, size, and control method.

Reference Price List – Shin Yi Butterfly Valves

The price of Shin Yi Butterfly Valves depends on the product series, size, material, control method, and connection type. Below is a reference price list for some commonly used models:

Shin Yi Lever Handle Butterfly Valve (WBLS – Wafer Type)

| Nominal Size (DN) | Unit Price (VND/set) |

|---|---|

| DN50 | 420,000 – 480,000 |

| DN65 | 510,000 – 580,000 |

| DN80 | 620,000 – 690,000 |

| DN100 | 750,000 – 820,000 |

| DN125 | 950,000 – 1,050,000 |

| DN150 | 1,100,000 – 1,250,000 |

Shin Yi Gear Handwheel Butterfly Valve (WBGS – with Gearbox)

| Nominal Size (DN) | Unit Price (VND/set) |

|---|---|

| DN200 | 1,850,000 – 2,000,000 |

| DN250 | 2,300,000 – 2,500,000 |

| DN300 | 2,900,000 – 3,200,000 |

| DN350 | 3,800,000 – 4,200,000 |

| DN400 | 4,500,000 – 5,000,000 |

Shin Yi Electric Actuated Butterfly Valve (EOM Series)

| Nominal Size (DN) | Price including Motor (VND/set) |

|---|---|

| DN80 | 4,200,000 – 4,800,000 |

| DN100 | 4,800,000 – 5,500,000 |

| DN150 | 6,200,000 – 7,000,000 |

| DN200 | 7,800,000 – 9,000,000 |

| DN300 | 10,500,000 – 12,000,000 |

| DN400 | 14,000,000 – 15,500,000 |

Note:

- The above prices exclude 10% VAT and may vary depending on the time of order, quantity, special materials (stainless steel, PTFE, etc.), or specific technical requirements.

- Electric actuated valves come with multiple options for voltage, torque, and control modes (ON/OFF – Modulating – Fail-safe).

- For large projects or bulk orders, customers can receive custom discounted quotations, along with preferential shipping and warranty policies.

Tips for Choosing the Right Shin Yi Butterfly Valve

To select the most suitable Shin Yi Butterfly Valve for your project, it is important to consider not only the price but also the technical factors and operating environment. The following are some practical tips from Thép Bảo Tín:

Identify the Correct Operating Environment

- Clean water, wastewater, compressed air → choose the WB/FB Series with EPDM or NBR seats, ductile iron body, and stainless steel disc.

- Light chemicals, hot steam, mildly corrosive solutions → prioritise stainless steel 316 discs and PTFE seats for enhanced durability.

- Automated systems → use the EOM Series (electric actuated valves), integrated with BMS or SCADA systems.

Choose the Appropriate Operation Method

- Lever handle: Quick operation, low cost – suitable for DN50 to DN150.

- Gear handwheel (worm gear): Ideal for high-pressure systems or sizes DN200 and above.

- Electric actuator: Integrated for automated systems, remote control, and high-precision requirements.

Check Connection Standards

- Identify your system’s flanges according to BS, JIS, DIN, or ANSI to select the correct wafer, lug, or flanged connection.

- Ensure flange dimensions and face-to-face distances are compatible.

Consider Construction Materials

- Ductile iron (FCD) body: Common, good pressure resistance, cost-effective.

- Stainless steel (CF8/CF8M) disc: Enhanced corrosion resistance, suitable for wastewater or light solvents.

- PTFE seat: Better heat and chemical resistance than EPDM, but at a higher cost.

Bao Tin Steel – Trusted Distributor of Shin Yi Butterfly Valves

When it comes to reputable industrial valve distributors in Ho Chi Minh City and Bac Ninh, Bao Tin Steel Co., Ltd is a name trusted by numerous customers, contractors, and investors over many years.

Thép Bảo Tín specialises in importing and distributing a wide range of industrial valves, including butterfly valves, ball valves, gate valves, safety valves, air release valves, check valves, and more from well-known domestic and international brands such as Shin Yi, YDK, Wonil, Giacomini, Kitz, and Yoshitake.

Among these, Shin Yi Butterfly Valves are one of the key products officially distributed by Bao Tin Steel. These valves are directly imported from Shin Yi’s factory in Vietnam, ensuring:

- 100% genuine products with full CO–CQ certification

- Wide range of sizes, materials, and operating types suitable for all applications

- Competitive pricing – ready stock – nationwide delivery

Shin Yi Valve Authorised Distributor Certificate of Thép Bảo Tín

-> See also: Shin Yi Lever-Operated Butterfly Valve

If you need consultation, quotation, or to place an order for Shin Yi butterfly valves, do not hesitate to contact Bao Tin Steel for the fastest and most accurate support!

📞 Hotline: 0932 059 176

📧 Email: bts@thepbaotin.com

📞 Hotline: 0932 059 176

Email: bts@thepbaotin.com

Tiger Steel is a subsidiary of Bao Tin Steel.

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ