DHC Gear-Operated Butterfly Valve

In water supply and drainage systems, wastewater treatment, and fire protection networks, selecting a valve that offers stable operation, easy control, and reliable sealing is always a top priority. The DHC gear-operated butterfly valve is one of the products that fully meet these requirements.

With its robust design, long service life, and precise opening/closing mechanism enabled by the handwheel and gearbox, the DHC butterfly valve is widely used across many industries in Vietnam. Beyond performance, it is also valued for its reasonable price, making it suitable for both civil and industrial projects.

In this article, Bao Tin Steel will provide a detailed overview of the design, technical specifications, practical applications, and the latest reference price list of the DHC gear-operated butterfly valve.

Design and Appearance

The valve body is made of ductile iron (FCD) or grey cast iron, coated with a signature blue epoxy paint of the DHC brand. This coating not only enhances the valve’s appearance but also provides corrosion and oxidation resistance, improving durability when operating in humid conditions, mild chemicals, or outdoor environments.

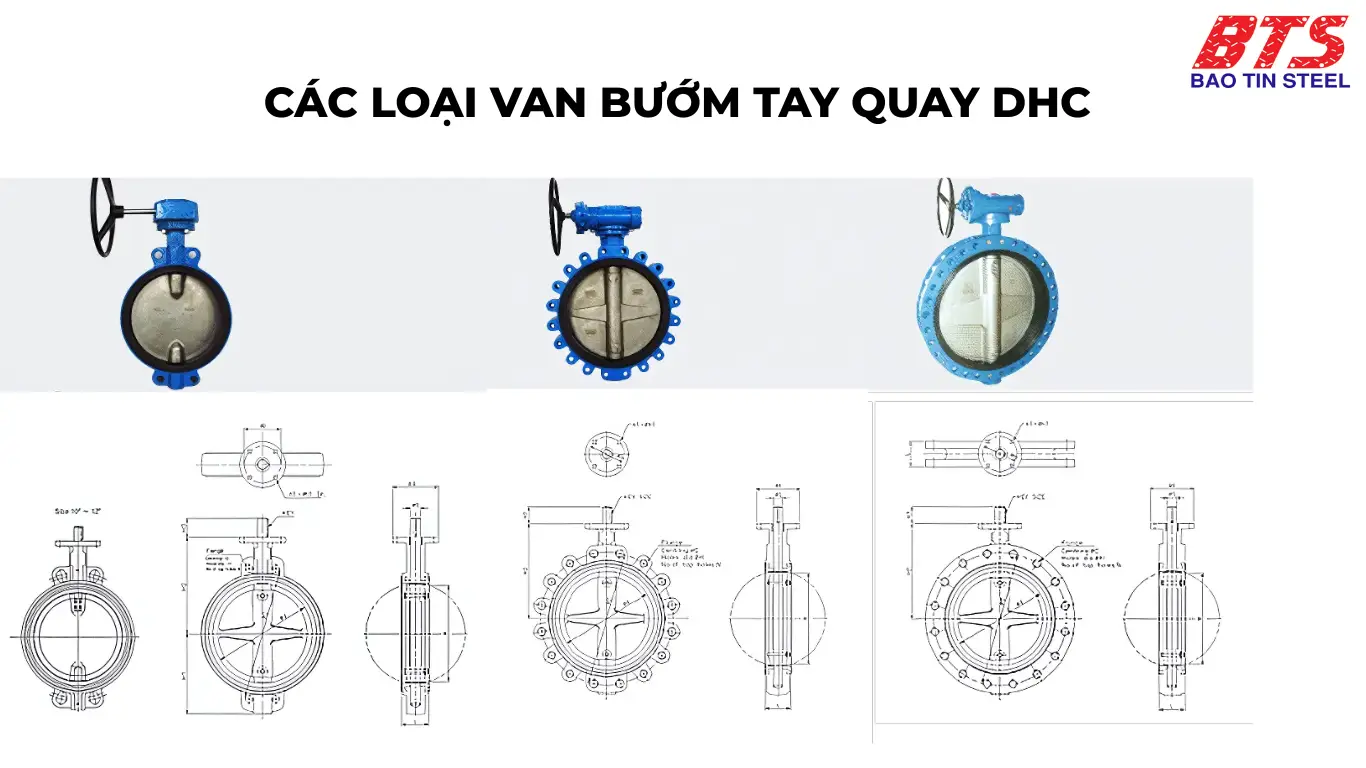

Depending on installation requirements, the valve is available in several body types:

- Wafer type: equipped with two alignment lugs, installed between two flanges.

- Lug type: features multiple threaded lugs for independent bolting.

- Flanged type: designed with integral flanges at both ends, ensuring higher rigidity and stability.

Actuation and Internal Components

The valve is operated via a round handwheel made of ductile iron or electrostatically coated steel, connected to a gearbox mounted on top of the valve body. The gearbox mechanism reduces manual effort, allowing the user to open or close the valve easily, even for larger sizes such as DN300 – DN600.

Inside the valve body, the disc is flat and circular, typically made of stainless steel 304/316 or nickel-plated cast iron, providing excellent wear resistance and a long service life under continuous operation. The shaft is securely fixed and can be removed for replacement when necessary.

The internal sealing gasket is integrally moulded with the body, made of EPDM or NBR, ensuring tight sealing, leak prevention, and easy maintenance when replacement is needed.

Technical Specifications – DHC Gear-Operated Butterfly Valve

The DHC gear-operated butterfly valve is designed in accordance with international standards, ensuring stable operation, high sealing performance, and easy installation across various systems.

- Brand: DHC

- Origin: South Korea or OEM per order

- Valve Type: Gear-operated butterfly valve – concentric (symmetrical stem)

- Actuation: Handwheel with gearbox

- Connection Types: Wafer, Lug, or Flanged

- Design Standards: ISO 5752, BS 5155, MSS SP-67, API 609

- Working Pressure: PN10, PN16 – maximum 16 bar

- Working Temperature: -10°C to 80°C (depending on seat material)

- Testing Standard: API 598 (pressure and tightness test)

- Nominal Size Range: DN50 – DN1200

- Valve Body Materials: Ductile iron (FCD), gray cast iron (FC), carbon steel, stainless steel (optional)

- Disc Materials: Stainless steel 304/316, nickel-plated cast iron, aluminium bronze

- Stem Materials: Stainless steel 304/420, K-Monel

- Seat Materials: EPDM, NBR, Viton, Silicone, Neoprene

- Top Flange (ISO Mount): ISO 5211 – compatible with electric or pneumatic actuators

- External Coating Color: Blue or Red Epoxy (depending on application: potable water / fire protection systems)

Additional Notes

- The valve can be equipped with an optional corrosion-resistant coating on the disc, depending on the requirements of mild chemical environments.

- For sizes DN350 and above, it is recommended to use a handwheel with a gearbox to reduce operating effort and ensure precise control.

=> Butterfly valve products you may be interested in: ShinYi handwheel butterfly valve

Key Advantages – DHC Gear-Operated Butterfly Valve

The DHC gear-operated butterfly valve is highly regarded not only for its robust design but also for its efficient operation, durability, and versatility across various systems. Key advantages include:

- Quick and precise operation: The handwheel, combined with a gearbox, enables smooth opening and closing of the valve with minimal effort.

- Excellent sealing performance: The valve uses high-elasticity EPDM, NBR, or Viton gaskets, ensuring leak-proof operation.

- High-quality materials: Constructed from ductile iron, stainless steel, or nickel-plated cast iron, with epoxy coating, providing long-lasting durability in harsh environments.

- Flexible installation options: Available in Wafer, Lug, or Flanged types, allowing fast and convenient integration into pipelines.

- Compliance with international standards: Meets JIS, BS, ANSI, DIN standards, making it suitable for water supply and drainage systems, fire protection (PCCC), HVAC, irrigation, and wastewater treatment plants.

Typical Applications – DHC Gear-Operated Butterfly Valve

Thanks to its robust design, stable operation, and high sealing performance, the DHC gear-operated butterfly valve is widely used across various industrial and infrastructure sectors. Key applications include:

- Water supply and drainage systems for residential and industrial areas.

- Municipal and industrial wastewater treatment systems.

- Fire protection systems (PCCC).

- HVAC systems in commercial buildings, data centres, and factories.

- Industrial pipelines or hydraulic structures, such as reservoirs and irrigation systems.

- Shipbuilding, food processing, and light chemical industries.

Reference Price List – DHC Gear-Operated Butterfly Valve [Updated 2025]

The following prices are for reference only for DHC gear-operated butterfly valves with ductile iron body, stainless steel disc, EPDM or NBR seat, and wafer connection. Actual prices may vary depending on material, connection standard (JIS, BS, ANSI), order quantity, or special requirements (red coating, corrosion resistance, etc.).

| Nominal Size (DN) | Reference Price (VND/unit) |

| DN50 |

750.000 – 950.000

|

| DN65 |

900.000 – 1.100.000

|

| DN80 |

1.100.000 – 1.350.000

|

| DN100 |

1.400.000 – 1.600.000

|

| DN125 |

1.800.000 – 2.100.000

|

| DN150 |

2.300.000 – 2.600.000

|

| DN200 |

3.800.000 – 4.300.000

|

| DN250 |

5.300.000 – 6.000.000

|

| DN300 |

6.800.000 – 7.800.000

|

| DN350 |

9.500.000 – 11.000.000

|

| DN400 |

11.500.000 – 13.500.000

|

| DN450 – DN600 |

Liên hệ báo giá theo dự án

|

| DN700 trở lên |

Báo giá riêng theo cấu hình kỹ thuật

|

Notes:

- Prices do not include VAT (10%) or shipping fees (if applicable).

- Large orders or project-based purchases will receive a custom quotation with attractive discounts.

- Both Flanged and Lug versions are available; prices may vary depending on the connection type and disc material.

Authorised Distributor of DHC Gear-Operated Butterfly Valves, Bao Tin Steel

It is undeniable that DHC butterfly valves, a reputable brand from South Korea, are a reliable choice for many piping systems due to their high durability and stable performance. However, the market currently has many unofficial or low-quality products, which may lead to technical issues or safety risks during use.

Choosing a trusted distributor is therefore essential to ensure you receive genuine, high-quality products as promised. If you are looking to purchase DHC gear-operated butterfly valves in Ho Chi Minh City, Bao Tin Steel is a name you can rely on.

Why choose Bao Tin Steel for DHC butterfly valves?

- Wide product range, ready stock: We supply DHC gear-operated butterfly valves from DN50 to DN600, compliant with JIS, BS, and ANSI standards.

- Clear origin and certification: All products come with CO and CQ, officially imported from South Korea.

- Competitive pricing: No middlemen – quick quotations, attractive discounts for large orders and projects.

- Professional technical support: Our experienced staff are ready to help you select the right valve for your system.

- Flexible payment and nationwide delivery.

Contact Bao Tin Steel now to receive a quotation for genuine DHC gear-operated butterfly valves and get advice on the best solution for your project!

- Hotline: 0932 059 176

- Email: kinhdoanh@thepbaotin.com

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ