A pressure-reducing valve is an essential component in technical systems such as water supply, compressed air, steam, and fire protection. When the inlet pressure is too high or fluctuates significantly, the valve helps regulate and maintain a stable outlet pressure. This protects pipelines and machinery, ensuring the safety of the entire system. It is an effective solution to prevent common issues such as leaks, pipe bursts, pump damage, or excessive energy loss.

In this article, Bảo Tín Steel will guide you through an overview of pressure reducing valves, including their definition, operating principles, practical applications, structure, and common types.

If you are looking for the right valve for your system, the information below will help you make a more accurate and confident decision.

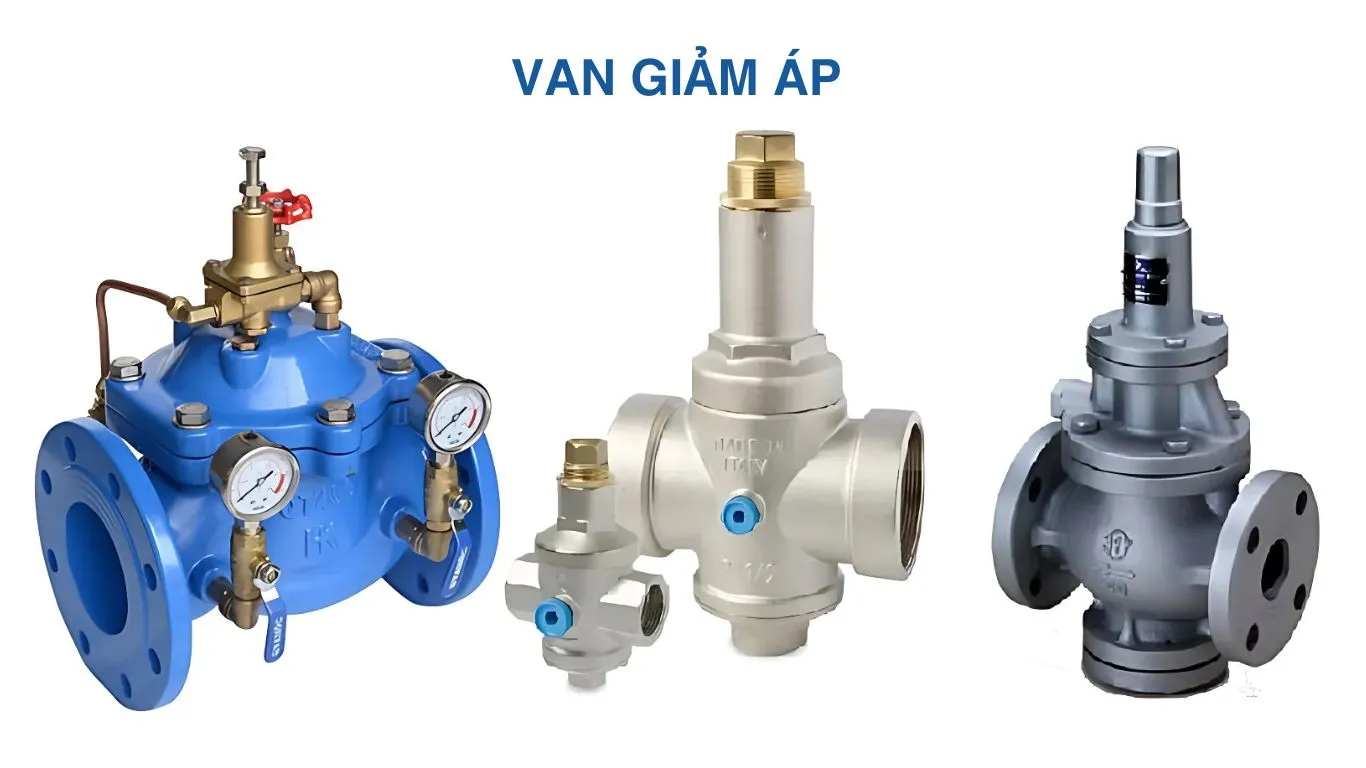

What is a Pressure Reducing Valve?

A pressure reducing valve is a device used to reduce and maintain the outlet pressure of a liquid or gas at a lower, stable level compared to the inlet pressure, regardless of fluctuations in the inlet pressure.

A pressure reducing valve abbreviated as PRV) is also referred to as a pressure regulator, pressure stabiliser, or pressure control valve.

.

.

Functions of a Pressure Reducing Valve

- Protects equipment such as pumps, boilers, pipelines, and nozzles from damage caused by overpressure or pressure shocks.

- Maintains stable outlet pressure, ensuring smooth operation of devices like spray nozzles, sensors, and CNC machines without water hammer or pneumatic surges.

- Saves energy by eliminating unnecessary excess pressure, especially in compressed air and hydraulic systems.

- Extends the lifespan of pipes and equipment, reduces maintenance costs, and prevents leaks, pipe bursts, or wear caused by prolonged high pressure.

- Ensures compliance with safety requirements in various applications, including high-rise buildings, manufacturing plants, and fire protection systems.

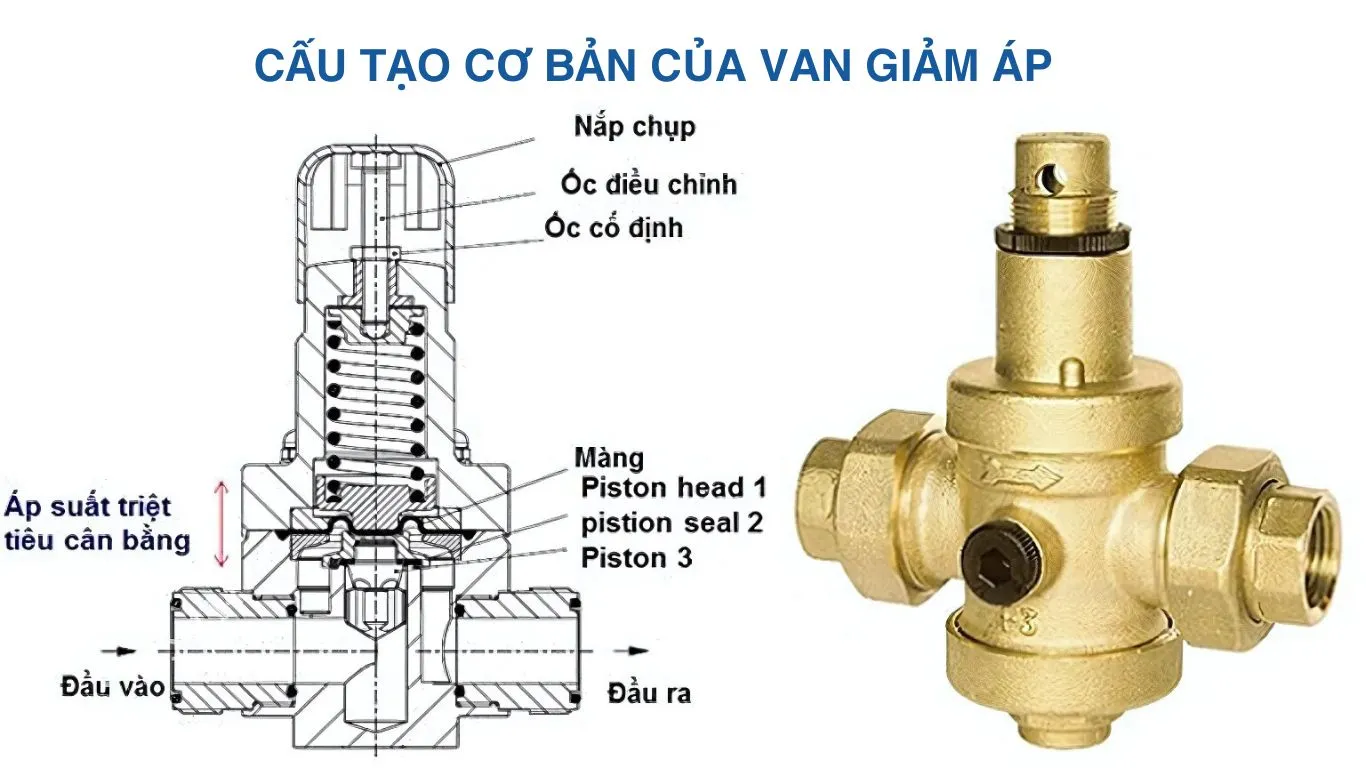

Structure of a Pressure Reducing Valve

A standard pressure-reducing valve typically consists of five main components, including:

Valve body: The outer casing, usually made of cast iron, brass, or stainless steel. This part comes into direct contact with the medium and withstands the full operating pressure.

Adjustment spring: Applies pressure on the diaphragm or piston. The spring force determines the maximum outlet pressure. Users can adjust the pressure via an external adjustment screw.

Diaphragm or piston: Directly responds to the outlet pressure. When the pressure exceeds the set level, the diaphragm or piston is pushed up, causing the valve disc to move and reduce the flow.

Valve disc: Controls the opening and closing of the flow path. It automatically adjusts its position to regulate the flow and maintain stable pressure.

Pressure adjustment screw: Usually located at the top or side of the valve. It allows users to turn the screw to increase or decrease the spring force, thereby changing the set pressure.

Operating Principle of a Pressure Reducing Valve

A pressure-reducing valve operates fully automatically based on a balance between the spring force and the outlet pressure. Specifically:

When the inlet pressure exceeds the set level, the flow pushes the diaphragm or piston upward. The valve disc then moves toward the closed position, reducing the flow cross-section and thereby lowering the outlet pressure.

Conversely, if the outlet pressure drops below the set level, the spring pushes the diaphragm or piston back to its original position. This opens the valve disc, increases the flow, and restores the outlet pressure to a stable level.

A key feature of the valve is its ability to maintain a stable outlet pressure even when the inlet pressure fluctuates continuously. This is achieved through an instantaneous feedback mechanism that continuously regulates the flow.

Common Types of Pressure Reducing Valves

There are several factors for classifying pressure-reducing valves. A typical classification is:

Classification by the type of medium used

Water Pressure Reducing Valve

This type of valve is specifically designed to regulate water pressure in domestic, commercial, or industrial water supply and drainage systems. It helps protect pipelines and water-using equipment such as washing machines and water heaters from excessive pressure while maintaining a stable water flow.

Compressed Air Pressure Reducing Valve

Widely used in compressed air systems, from manufacturing plants to mechanical workshops. This valve reduces the high pressure from storage tanks to a safe and suitable level for equipment such as air cylinders, spray guns, and other pneumatic tools.

Steam Pressure Reducing Valve

This valve is specially designed for high-temperature and high-pressure steam systems. Made from heat-resistant and pressure-resistant materials, it reduces steam pressure before it enters heat exchangers or machinery that uses steam.

Classification by Design

Diaphragm-type Pressure Reducing ValveUses a thin rubber or metal diaphragm as the pressure-sensing component. This type of valve is highly sensitive and responds quickly to pressure changes, making it suitable for applications that require high precision.

Piston-type Pressure Reducing Valve

Uses a metal piston instead of a diaphragm. Piston valves are more durable, can withstand higher pressures, and are less affected by temperature, making them ideal for heavy-duty industrial systems.

Classification by Connection Type

Threaded Valve

This type of valve has internal or external threads and is commonly used for small-diameter, low-pressure pipelines or in residential and domestic systems. Installation and replacement are easy.

Flanged Valve

This valve is connected to the pipeline using flanges, bolts, and gaskets for sealing. It is mainly used in industrial systems with large-diameter, high-pressure pipelines, ensuring tightness and reliability.

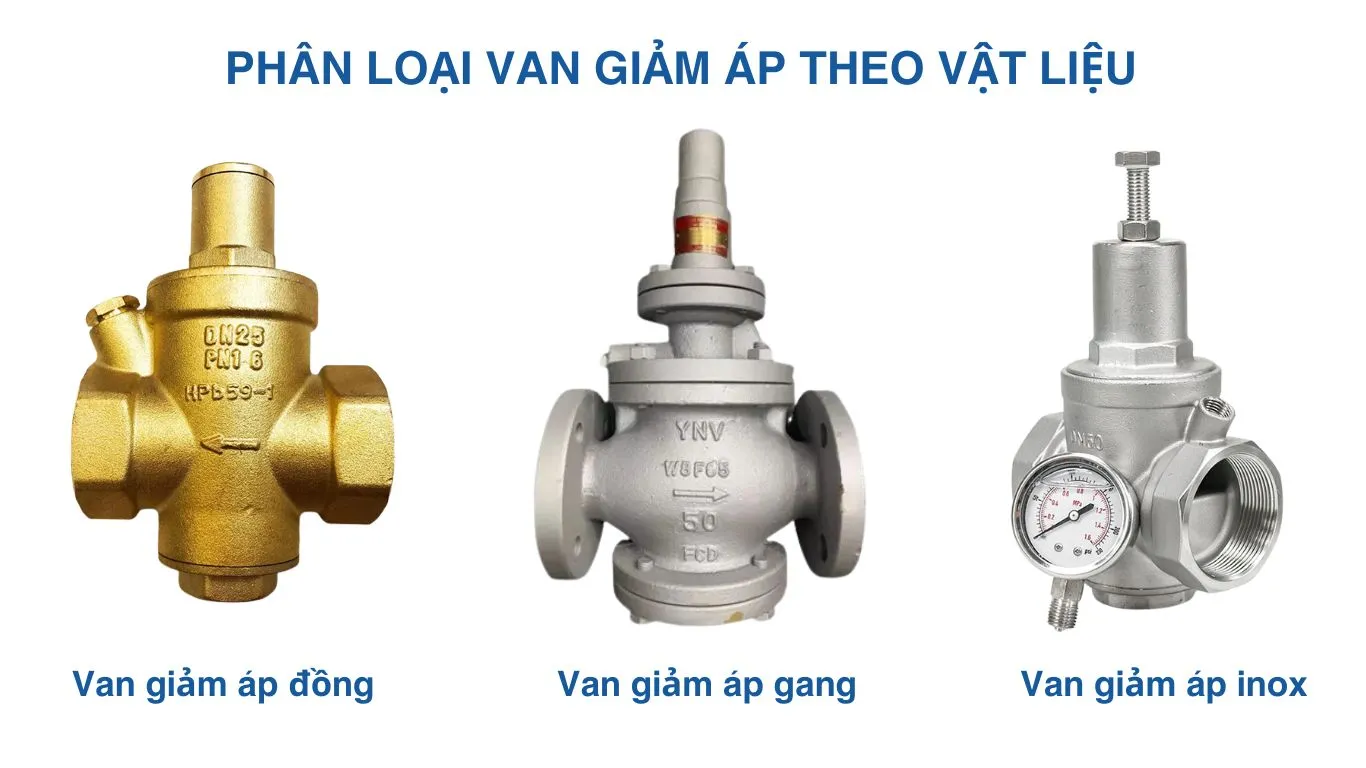

Classification by Material

Brass Valve

Commonly used in domestic water supply systems due to its good corrosion resistance, safety for potable water, and affordable cost.

Cast Iron Valve

A popular choice for cold water systems and large pipelines in factories or buildings because of its high durability and reasonable price.

Stainless Steel Valve

Offers superior corrosion resistance and can withstand high temperatures and pressures. Stainless steel valves are used in special environments such as chemical, clean water, food, pharmaceutical applications, or other highly corrosive conditions.

Applications of Pressure Reducing Valves

Pressure reducing valves are widely used in both residential and industrial systems due to their ability to flexibly and stably control pressure. Common applications include:

- Used in water supply systems for houses, apartment buildings, and hotels.

- Compressed air systems in factories and production workshops.

- Steam and boiler systems.

- Stabilising output pressure for fire hoses, hydrants, and sprinklers.

- Used in clean water supply systems, medical gas systems, or other specialised piping systems.

How to Install a Pressure Reducing Valve

Step 1: Determine the pressure level of the system that needs reduction, as well as the pipe size, to select the appropriate valve type.

Step 2: Once the suitable pressure-reducing valve is chosen, install a pressure gauge on the valve body to monitor operating pressure.

Step 3: Install the pressure-reducing valve into the system. Ensure it is securely fitted and installed in the correct flow direction. Also, install two gauges at the inlet and outlet sides of the valve.

Step 4: Allow the fluid or gas to pass through the valve and check for any leaks. If there are no issues, the system can operate normally.

Some Notes When Selecting and Installing a Pressure Reducing Valve

- Choose the correct type of valve according to the medium (water, air, steam, etc.) and the system’s operating pressure.

- Install the valve in the correct flow direction, following the arrow on the valve body.

- Place the valve in an easily accessible location for inspection and maintenance, avoiding damp or hard-to-reach areas.

- Set the outlet pressure according to the system’s requirements to prevent overpressure or insufficient pressure.

- Regularly check and clean the valve to ensure stable operation and prolong its service life.

Conclusion

A pressure-reducing valve is an essential device in many modern technical systems, helping to control and maintain stable pressure. This protects equipment and improves operational efficiency.

Understanding the structure, operating principle, and classification of pressure reducing valves will help you select the right product, suitable for your specific usage needs and working environment.

To ensure long-term safety and efficiency, prioritise choosing valves from reputable suppliers that provide complete installation and maintenance instructions, as well as clear technical support. Thép Bảo Tín is one such supplier you can consider today!

Bao Tin Steel is a certified Shin Yi valve distributor.

In addition, Bao Tin Steel also provides a wide range of steel products, including steel pipes, steel tubes, steel profiles, steel plates, as well as pipe fittings and fire protection materials. If you need a quote for any type of material, feel free to contact us:

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ