The ARV ABF600 Lever-operated Butterfly Valve is a 90-degree rotary on/off valve, operated by a manual lever. It is designed in a wafer type, suitable for installation between two standard flanges. The valve is manufactured from high-quality materials such as GGG50 ductile iron, stainless steel shaft, and EPDM/NBR seat, with a full epoxy coating inside and out for excellent corrosion resistance.

With a working pressure of up to 16 bar and a maximum operating temperature of 80°C, this valve is especially suitable for clean water, wastewater, seawater, light chemicals, and other industrial applications that require high durability and tight sealing.

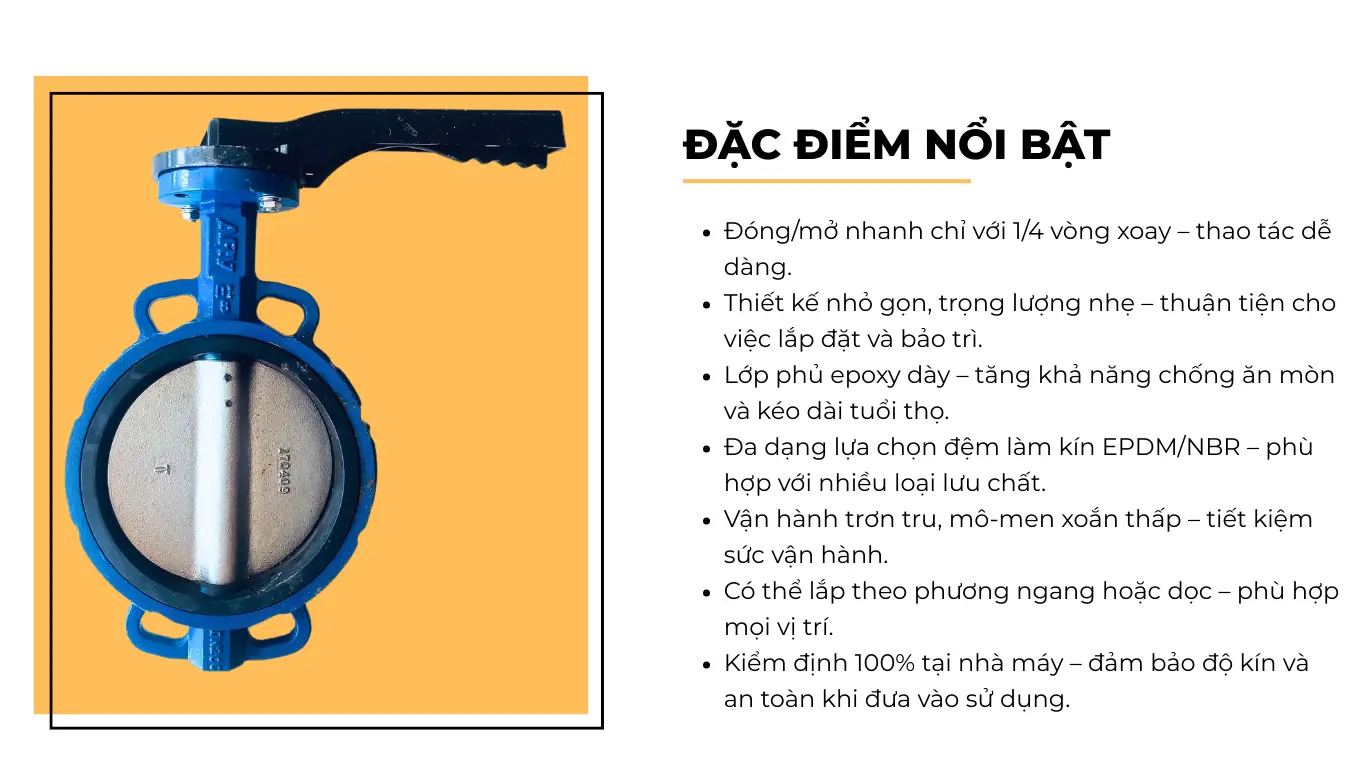

Outstanding Features of the ARV ABF600 Lever-operated Butterfly Valve

Not only favoured for its high-quality materials, the ARV ABF600 lever-operated butterfly valve also offers several outstanding advantages:

- Quick 1/4-turn operation:

The valve operates with a 90-degree rotary mechanism, enabling fast and efficient flow control, saving operation time. - Compact design – Easy installation:

Wafer-type connection fits between two standard flanges, saving space and simplifying the installation process. - High-quality materials – Superior corrosion resistance:

Valve body and disc are made from high-strength GGG50 ductile iron, with a stainless steel shaft and electrostatic epoxy coating inside and out for excellent corrosion protection. - Multiple sealing options:

Depending on the application, the valve can be equipped with EPDM or NBR seats, making it suitable for clean water, wastewater, seawater, or mildly corrosive fluids. - Stable flow – Low pressure loss:

The double-offset design minimises flow resistance, ensuring stable flow and reduced pressure drop across the valve. - Flexible installation:

Can be installed in any pipe orientation—horizontal, vertical, or inclined—offering convenience in system design. - Long service life – Low maintenance cost:

Thanks to precise engineering and durable materials, the valve operates smoothly with low torque, reducing wear and minimising maintenance expenses. - Strict quality assurance standards:

100% of valves are pressure-tested (shell and seat tests) at the factory in accordance with EN 12266-1, ensuring high reliability before delivery.

Technical Specifications – ARV ABF600 Lever-operated Butterfly Valve

| Item | Description |

|---|---|

| Design Standard | EN 593 / BS 5155 |

| Connection Type | Wafer, ISO 7005-1 / EN 1092-1 |

| Face-to-face Dimension | EN 558 / ISO 5752 |

| Marking | EN 19 |

| Pressure Testing Standard | EN 12266-1 |

| Maximum Working Pressure | 16 bar |

| Shell Test Pressure | 24 bar |

| Seat Test Pressure | 17.6 bar |

| Maximum Operating Temperature | 80°C |

| Body Material | Ductile Iron EN-GJS-500 (GGG50) |

| Disc Material | Ductile Iron EN-GJS-500 (GGG50) |

| Shaft Material | Stainless Steel |

| Seat Material | EPDM or NBR |

| Handle Type | Cast Iron (Grey Iron) |

| Gaskets and Retaining Rings | Steel, Stainless Steel, DIN Standard |

| Corrosion Protection Coating | Electrostatic Epoxy Coating |

Detailed specification table:

| Model | DN (mm) | A (mm) | B (mm) | C (mm) | k (mm) | n x Øl | M (mm) | L (mm) |

| ABF600-50 | 50 | 32 | 126 | 80 | 125 | 4 x Ø19 | 190 | 43 |

| ABF600-65 | 65 | 32 | 134 | 89 | 145 | 4 x Ø19 | 190 | 46 |

| ABF600-80 | 80 | 32 | 157 | 95 | 160 | 4 x Ø19 | 190 | 46 |

| ABF600-100 | 100 | 32 | 167 | 114 | 180 | 4 x Ø19 | 255 | 52 |

| ABF600-125 | 125 | 32 | 180 | 127 | 210 | 4 x Ø19 | 255 | 56 |

| ABF600-150 | 150 | 32 | 203 | 139 | 240 | 4 x Ø23 | 255 | 56 |

| ABF600-200 | 200 | 45 | 228 | 175 | 295 | 4 x Ø23 | 355 | 60 |

Applications of ARV ABF600 Lever-operated Butterfly Valve

The ARV ABF600 lever-operated butterfly valve is designed to meet the demands for flexible operation, high sealing performance, and exceptional durability across various industries. Typical applications include:

- Urban water supply and drainage systems:

Used to control flow in municipal water distribution networks, clean water supply systems, and wastewater treatment systems. - Pumping stations and water treatment plants:

Installed at water inlets, reservoirs, circulation pumps, or in industrial water treatment processes. - Industrial pipelines:

Applied in food & beverage manufacturing, light chemical industries, and other plants requiring frequent and fast open/close operations. - Thermal power plants and cooling systems:

Used in circulating cooling water systems in power generation facilities and energy infrastructure. - Seawater applications:

With NBR seat options and thick epoxy coating, the valve is suitable for seawater piping systems in fisheries or marine ports. - Installation in technical rooms and valve cabinets:

Compact size allows for easy installation in confined spaces such as valve pits, technical cabinets, or control rooms. - Construction and fire protection systems:

Serves as an isolation valve in water supply systems for high-rise buildings, industrial zones, or in combination with fire protection equipment.

Economic Benefits of Using the ARV ABF600 Lever-operated Butterfly Valve

In addition to its superior technical features, the ARV ABF600 lever-operated butterfly valve offers several practical economic advantages:

- Lower initial investment cost:

Compared to gate valves or globe valves of the same size, the lever-operated butterfly valve is significantly more cost-competitive, helping reduce the overall initial material costs for projects. - Savings in installation and transportation costs:

Its compact design and lightweight construction make transportation, handling, and installation easier—especially beneficial for projects with limited space or difficult access. - Energy savings during operation:

Thanks to low torque and a double-offset shaft design that reduces pressure loss, the system consumes less electricity when operating pumps, contributing to long-term energy cost reduction. - Long service life – reduced maintenance and replacement costs:

Durable materials, thick epoxy coating, and a simple operating mechanism minimise damage, extending valve life and reducing the frequency and cost of periodic maintenance or replacements. - Versatility – reduced valve inventory:

With flexible use for various fluids (clean water, wastewater, seawater, etc.), the valve simplifies material management and optimises inventory costs. - Compliance with inspection standards – savings on legal and technical inspection costs:

The valve is 100% factory pressure-tested according to EN 12266-1, saving time and expenses on field inspections and legal approvals.

Installation, Operation Instructions and Safety Precautions

To ensure optimal performance and system durability, please pay attention to the following technical guidelines during installation and operation:

Installation Instructions

Preparation before installation:

- Check the valve size and type against the system specifications.

- Clean the pipeline thoroughly, removing any dirt, rust, or debris that may obstruct valve operation.

- Ensure the flange faces conform to the wafer connection standard (EN 1092-1).

Valve installation:

- Place the valve between the two flanges, ensuring the disc is opened by 1/4 turn to prevent jamming during bolt tightening.

- Tighten bolts evenly in a cross pattern to avoid misalignment and ensure proper sealing.

- Do not apply excessive force on the lever or valve shaft before the valve is fully secured.

- The valve can be installed in horizontal or vertical pipe orientations, depending on the pipeline layout.

Post-installation checks:

- Operate the lever several times to confirm smooth disc rotation.

- Check sealing integrity by running fluid through the system and inspecting for leaks.

Operating Instructions

The valve is manually operated with a lever, rotating 90° for full open/close:

-

Lever horizontal = Open

-

Lever vertical = Closed

Do not operate the valve too quickly or apply excessive force to avoid bending the shaft or damaging the sealing seat.

Use the valve only with compatible fluids according to the seat material (EPDM is suitable for clean water, NBR for light oils or seawater, etc.).

Safety Precautions During Use

- Do not operate the valve in environments exceeding the allowed temperature or pressure limits (maximum 80°C and 16 bar).

- Never disassemble the valve while the system is still under pressure; always drain the fluid and ensure safety before performing maintenance.

- Regularly inspect the valve’s operating condition, especially the sealing seat and lever.

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and helmets when installing or removing the valve.

- Do not use the valve as a support point to bear pipe loads to avoid shaft bending or deformation.

Buy Genuine ARV ABF600 Lever-operated Butterfly Valve at Bao Tin Steel

As a trusted distributor of industrial valves in Vietnam and Cambodia, Bao Tin Steel Co., Ltd. offers genuine ARV ABF600 butterfly valves with complete CO-CQ certification, competitive pricing, and professional after-sales service.

- Guaranteed genuine products with a clear warranty

- Fast delivery and dedicated technical support

- Special discounts for projects and agents

Contact us today for the best quotation:

-

- Hotline: 0932 059 176

- Email: kinhdoanh@thepbaotin.com

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ