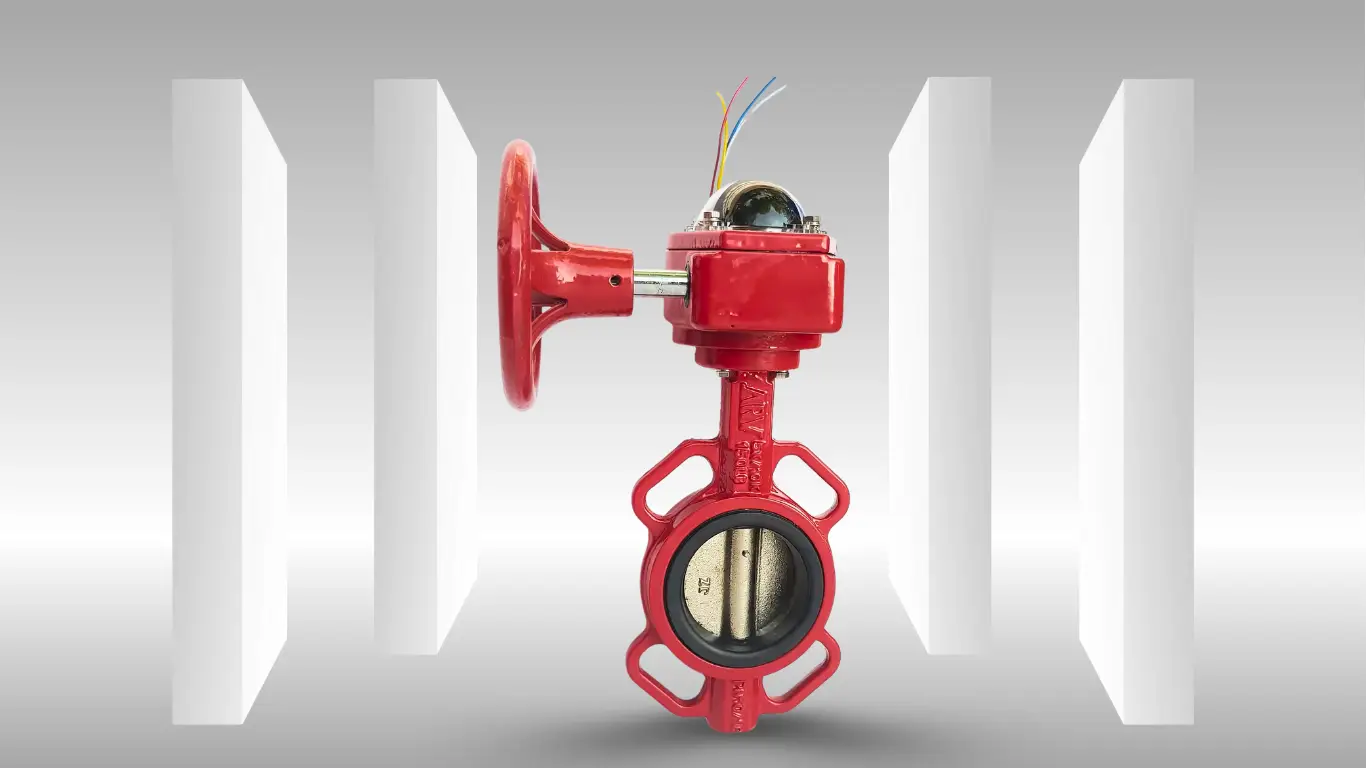

The ARV – ABFS 650 Electric Signal Butterfly Valve is a Wafer-type butterfly valve integrated with an electrical signal box (Switcher Gear Operator), used to indicate the open/closed status of the valve. This product is specifically designed for fire protection systems (FFS) and water supply and drainage systems, providing effective flow control and isolation. The valve features high sealing performance, easy operation, and is suitable for installation in factories, pumping stations, water treatment systems, and other industrial facilities.

Key Features of the ARV – ABFS 650 Electric Signal Butterfly Valve

- Integrated electrical signal box (Switcher Gear Operator) allows monitoring of the valve’s open/closed status — especially useful in automatic fire protection systems and remote control applications.

- Compact Wafer-type design for easy installation between two flanges, saving space and compatible with various piping systems.

- Monoblock disc and shaft, with a spherical-machined and polished disc surface, ensures tight sealing and reduced torque during operation.

- It can be installed vertically on pipelines and operates with a 90° rotation.

- No need for flange gaskets thanks to the pre-moulded groove and O-ring seal design.

- Entire internal and external surfaces are coated with epoxy ≥ 300 microns, enhancing corrosion resistance.

- Applications: Fire protection systems, water treatment, power plants, industrial facilities, seawater systems, water tanks, pumping stations, and more.

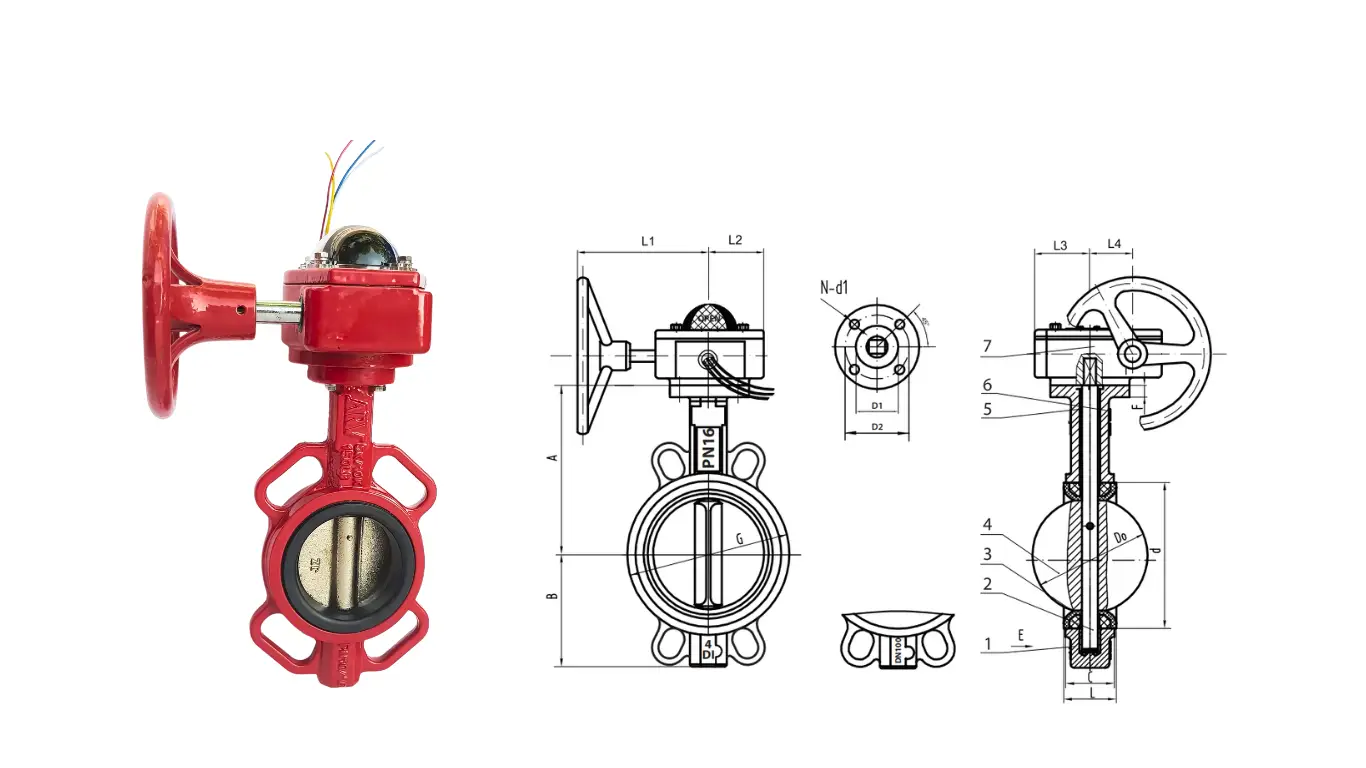

Detailed technical specifications of ARV electric signal butterfly valve

| Specification | Value |

|---|---|

| Model | ABFS 650 |

| Nominal Diameter (DN) | DN65 to DN300 |

| Working Pressure | 16 bar (PN16) |

| Body Test Pressure | 24 bar |

| Seat Test Pressure | 17.6 bar |

| Maximum Operating Temperature | 80°C |

| Design Standard | EN 593 |

| Connection Standard | Wafer type – ISO 7005-1, EN 1092-1 |

| Face-to-Face Dimension | EN 558-1 / ISO 5752 |

| Testing Standard | EN 12266-1 |

| Corrosion Protection | Electrostatic epoxy coating ≥ 300 microns (internal & external surfaces) |

| Operation Type | Manual handwheel with integrated electrical signal box (Switcher Gear Operator) |

| Main Materials | |

| – Valve Body | Ductile Iron |

| – Disc | Ductile Iron with EPDM coating |

| – Shaft | Stainless Steel SS304 |

| – O-ring | EPDM |

| – Bearing | PTFE |

| – Signal Box | Ductile Iron |

Detailed specification table

| Model | DN (mm) | A (mm) | B (mm) | C (mm) | Do (mm) | G (mm) | Số lỗ x Ølỗ | L (mm) |

| ABFS650-65 | 65 | 136 | 82 | 46 | 64 | 108 | 4 x 19 | 49 |

| ABFS650-80 | 80 | 142 | 91 | 46 | 79 | 123 | 4 x 19 | 49 |

| ABFS650-100 | 100 | 163 | 107 | 52 | 104 | 154 | 4 x 19 | 55 |

| ABFS650-125 | 125 | 176 | 107 | 56 | 123 | 180 | 4 x 19 | 59 |

| ABFS650-150 | 150 | 197 | 127 | 56 | 156 | 210 | 4 x 23 | 59 |

| ABFS650-200 | 200 | 230 | 143 | 60 | 202 | 263 | 4 x 23 | 64 |

| ABFS650-250 | 250 | 268 | 165 | 66 | 256 | 311 | 4 x 28 | 70 |

| ABFS650-300 | 300 | 293 | 185 | 73 | 306 | 362 | 4 x 28 | 78 |

Practical Applications of the ARV – ABFS 650 Electric Signal Butterfly Valve

The ABFS 650 electric signal butterfly valve is designed to meet stringent requirements in industrial and technical infrastructure systems. Typical applications include:

- Fire protection systems (FFS)

- Urban and industrial water supply and drainage systems

- Installation on inlet/outlet pipelines of storage tanks, pumping stations, water and wastewater treatment equipment

- Use in seaports, seawater cooling systems, and ships

- Cooling water and return water pipelines in thermal power plants and hydropower plants

- Food, pharmaceutical, chemical, paper, and cement factories, among others

Economic Benefits of Using the ARV – ABFS 650 Electric Signal Butterfly Valve

The ABFS 650 electric signal butterfly valve not only ensures technical efficiency but also brings significant economic benefits to investors and operators.

Firstly, the product is reasonably priced compared to imported European valve models while still meeting international technical standards such as EN 593 and EN 12266-1. Its compact wafer design saves installation materials like flanges and bolts, and eliminates the need for additional sealing gaskets, thereby significantly reducing initial investment costs.

In terms of operation, the valve features a monoblock disc shaft, double-layer sealing rings, and PTFE bearings, which help limit wear, minimise damage, and extend service life. The surface is coated with a minimum 300-micron epoxy layer, enhancing corrosion resistance in water, seawater, or wastewater environments, thus reducing periodic maintenance costs.

Another highlight is the integrated electrical signal box, which allows managers to easily monitor the valve’s open/closed status remotely. This is especially important in fire protection systems, where detecting a mistakenly closed valve can help prevent severe damage caused by fire or water loss.

Additionally, the valve operates with low torque and is easy to handle, reducing the power required when using actuators or labour needed for manual operation. Consequently, the system runs more smoothly and stably, with fewer interruptions or failures.

Installation, Operation, and Safety Instructions

Installation Instructions

Preparation before installation:

- Thoroughly check the valve’s model, size, working pressure, and surface condition before integrating it into the system.

- Clean the flange faces and piping, removing dust, debris, rust, or any foreign objects inside the pipe.

- Ensure the distance between the two flanges matches the valve’s face-to-face dimension (according to the “L” specification).

Installation Steps:

- Place the valve between the two flanges, ensuring the valve disc is in an open position at about 10–20° to avoid collision with the flange edges when tightening the bolts.

- Align the bolt holes symmetrically, then gradually tighten the bolts in a cross pattern to evenly distribute pressure.

- Check that the valve disc rotates freely without sticking or rubbing against the flanges.

- After securing the valve, perform a pressure test according to system standards to verify the seal integrity.

Operating Instructions

- The valve is operated manually using a handwheel integrated with an electric signal box (gear operator).

- Turn the handwheel clockwise to close the valve, and counterclockwise to open it.

- The open/closed status is indicated via the signal box or transmitted to the control panel.

- The valve is suitable for use as a main shut-off valve, regulating valve, or zone valve within the system.

Safety Notes

- Do not install the valve against the flow direction when the system is under high pressure — carefully refer to the technical drawings.

- Do not use the valve for continuous throttling at high flow rates to avoid wear on the disc surface or EPDM seat.

- Do not operate the valve with excessive force after reaching the end of travel — this may damage the gear operator or shaft.

- In seawater or chemically contaminated wastewater environments, periodically inspect the epoxy coating and EPDM seals.

- Disconnect the power supply before inspecting or maintaining the signal box to ensure electrical safety.

Periodic Maintenance

- Check mechanical operation (handwheel, shaft, disc) every 6 months.

- Regularly inspect the electrical signal to ensure connection with the central monitoring system.

- Clean the exterior and corrosion protection coating annually if operating in humid, chemical, or seawater environments.

Purchase Genuine ARV ABFS 650 Butterfly Valve at Thep Bao Tin

If you are looking for a genuine ARV–ABFS 650 electric signal butterfly valve, complete with documentation and reasonable prices, Thep Bao Tin is a trusted address you can rely on.

Thep Bao Tin specialises in supplying industrial valves, fire protection equipment, and genuine piping accessories, fully meeting technical requirements and project documentation.

Vì sao nên mua van tại Thép Bảo Tín?

- Provide CO/CQ and delivery notes upon request

- Support quotations based on valve quantity and size

- Nationwide delivery, ensuring project schedule compliance

- Attractive discounts for bulk orders or projects

Hotline: 0932 059 176

Email: kinhdoanh@thepbaotin.com

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ