Brass ball valves are made from brass or red brass (bronze). They stand out thanks to their good thermal conductivity, moderate corrosion resistance, stable operation, and most importantly, affordable price suitable for most projects.

This article provides a complete overview of brass ball valves – from definition, structure, working principle, specifications, classification, practical applications, to a reference price list – helping you understand and choose the right valve for your system.

What is a Brass Ball Valve?

A brass ball valve is a type of valve made from brass. Its internal structure includes a spherical ball with a hole through the centre and a flow passage inside the body. The ball rotates 90° to either allow or block the flow of liquid or gas.

Brass ball valves are easily recognisable by their distinctive yellow-golden colour, compact body, and threaded (male or female) end connections. The handle is usually coated in red or blue plastic for insulation and easy identification of the valve’s open/closed state.

Compared with stainless steel ball valves, brass valves are more affordable and easier to machine, though less resistant to strong chemicals. Compared with cast iron valves, they are lighter, easier to install, and ideal for small piping systems and civil applications.

Advantages of Brass Ball Valves

- Affordable cost – Significantly cheaper than stainless steel valves, helping reduce investment costs for small and medium systems.

- Moderate corrosion resistance & good thermal conductivity – Brass resists oxidation in clean water and compressed air systems, and its high thermal conductivity makes it suitable for hot water systems.

- Lightweight & easy installation – Compact design, ideal for threaded piping in residential water systems, compressed air, and household applications.

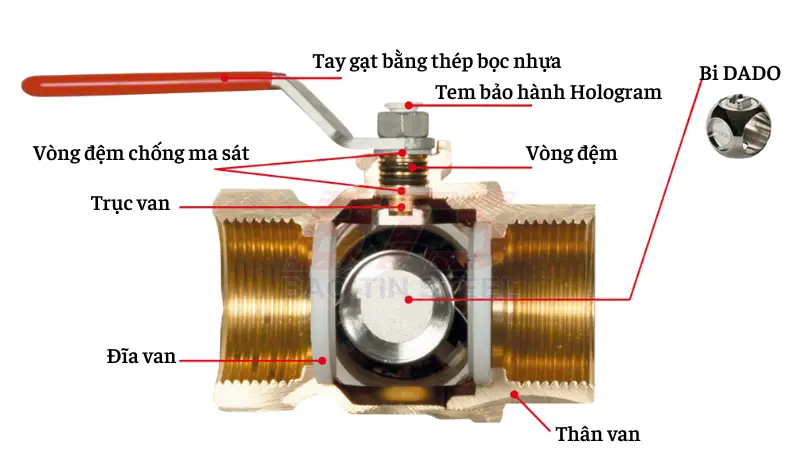

Structure of Brass Ball Valves

Brass ball valves have a simple but effective structure, typically including 5 main parts:

- Valve body – Made from brass or red brass, housing and protecting internal components.

- Ball – A hollow sphere with a through-hole, usually nickel-plated brass or stainless steel, ensuring smooth and tight operation.

- Stem (shaft) – Connects the handle to the ball, transmitting rotational movement.

- Handle – Usually steel or stainless steel, covered with red/blue plastic insulation.

- Seals (packing) – Typically PTFE (Teflon) or EPDM, ensuring leak-proof shutoff.

Working Principle

Brass ball valves operate by rotating the stem, which turns the ball inside.

- When the hole in the ball aligns with the flow direction, liquid or gas passes through.

- When rotated 90°, the ball blocks the passage, stopping flow completely.

These valves are bi-directional, meaning they can be installed in either flow direction without affecting performance.

Types of Brass Ball Valves

By connection type:

- Threaded (BSP, BSPT, NPT) – Most common, used in household and small piping systems.

- Flanged – For larger systems requiring higher sealing performance.

By body design:

- 1-piece (1PC) – Single body construction.

- 2-piece (2PC) – Two-part body, easy to assemble.

- 3-piece (3PC) – Three-part body, easy to maintain and replace internal parts.

By operation method:

- Lever-operated – Standard manual control.

- Electric actuator-operated – Automatic, remote control.

- Pneumatic actuator-operated – Automatic, air-driven.

By port configuration:

- 2-way – Standard, one inlet and one outlet.

- 3-way – Used for flow diversion or mixing (T-port and L-port).

Technical Specifications

| Specification | Details |

|---|---|

| Size | DN15 – DN100 (1/2″ – 4″) |

| Body Material | Brass (standard), Red brass, Pure copper |

| Connection | Threaded (BSPP, BSPT, NPT), Flanged, Welded, Quick-connect |

| Working Pressure | PN10 – PN40 (10–40 bar), higher pressure options available |

| Working Temperature | -10°C to 120°C (standard), higher temperature options available |

| Suitable Media | Clean water, compressed air, steam (limited), gas, oil, and some chemicals |

| Operation | Lever, gearbox, electric actuator, pneumatic actuator |

| Seal Material | PTFE (Teflon), NBR, EPDM, RPTFE |

| Standards | BS, DIN, ANSI, JIS, ISO |

Reference Price List – Brass Ball Valves

💡 Notes:

- Prices are indicative, based on popular brands such as Miha, Minh Hòa, Shin Yi, ARV, and OEM China.

- Common connection: BSP or NPT threaded, lever-operated.

- Prices exclude VAT, delivery, and may vary depending on time and supplier.

| Size (DN) | Size (inch) | Reference Price (VND/unit) |

|---|---|---|

| DN15 | 1/2″ | 80,000 – 130,000 |

| DN20 | 3/4″ | 100,000 – 180,000 |

| DN25 | 1″ | 130,000 – 220,000 |

| DN32 | 1 1/4″ | 180,000 – 300,000 |

| DN40 | 1 1/2″ | 250,000 – 350,000 |

| DN50 | 2″ | 300,000 – 450,000 |

| DN65 – DN80 | 2 1/2″ – 3″ | 500,000 – 800,000 |

| DN100 | 4″ | 850,000 – 1,200,000 |

📞 Contact us directly for an updated quotation and bulk pricing support.

Applications of Brass Ball Valves

- Domestic water supply and drainage systems (households, apartments, civil works).

- Compressed air systems in factories and workshops.

- Oil and low-to-medium pressure gas pipelines.

- HVAC and air conditioning systems.

- Water filtration systems.

- Solar water heating systems.

- Industrial sectors: clean water treatment, wastewater, low-pressure steam (<90°C), petroleum, and certain chemical processes.

Bao Tin Steel – Trusted Supplier of Brass Ball Valves

If you are looking for a reliable supplier of genuine brass ball valves with competitive pricing, Bao Tin Steel Co., Ltd. is your trusted partner.

We distribute brass ball valves ranging from DN15 to DN100, with various designs and connection types (threaded or flanged), meeting both residential and industrial needs.

Our products come from trusted brands such as Shin Yi, Miha, Minh Hòa, ARV, with full CO–CQ certification and clear origin. Alongside, we provide professional technical consultation and nationwide fast delivery.

With many years of experience in industrial materials and piping systems, Bao Tin Steel is committed to delivering the most suitable solution for your project.

📞 Call us today for a quotation and consultation: Hotline: 0932 059 176

Tiger Steel is a subsidiary of Bao Tin Steel.

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ