In the context where automation and system safety are increasingly emphasised, choosing equipment that not only controls but also monitors operational status is essential. The butterfly valve with monitoring switch is precisely the choice that many system engineers, investors, and modern fire protection management teams are prioritising.

At Bao Tin Steel, we understand that you don’t just need a valve to open/close—you need a “smart link” in your operational monitoring system, helping to minimise risks and enhance the safety of your projects.

What is a butterfly valve with a monitoring switch?

This is essentially a traditional butterfly valve with an added monitoring switch attached to its gearbox. This setup allows you to know whether the valve is open or closed directly from your control centre, without needing to physically check it on-site.

The valve works by rotating a disc 90 degrees to either open or close the flow. As the disc rotates, the monitoring switch (also known as a tamper switch) sends an electrical signal back to your system, such as SCADA, BMS, or the fire alarm panel.

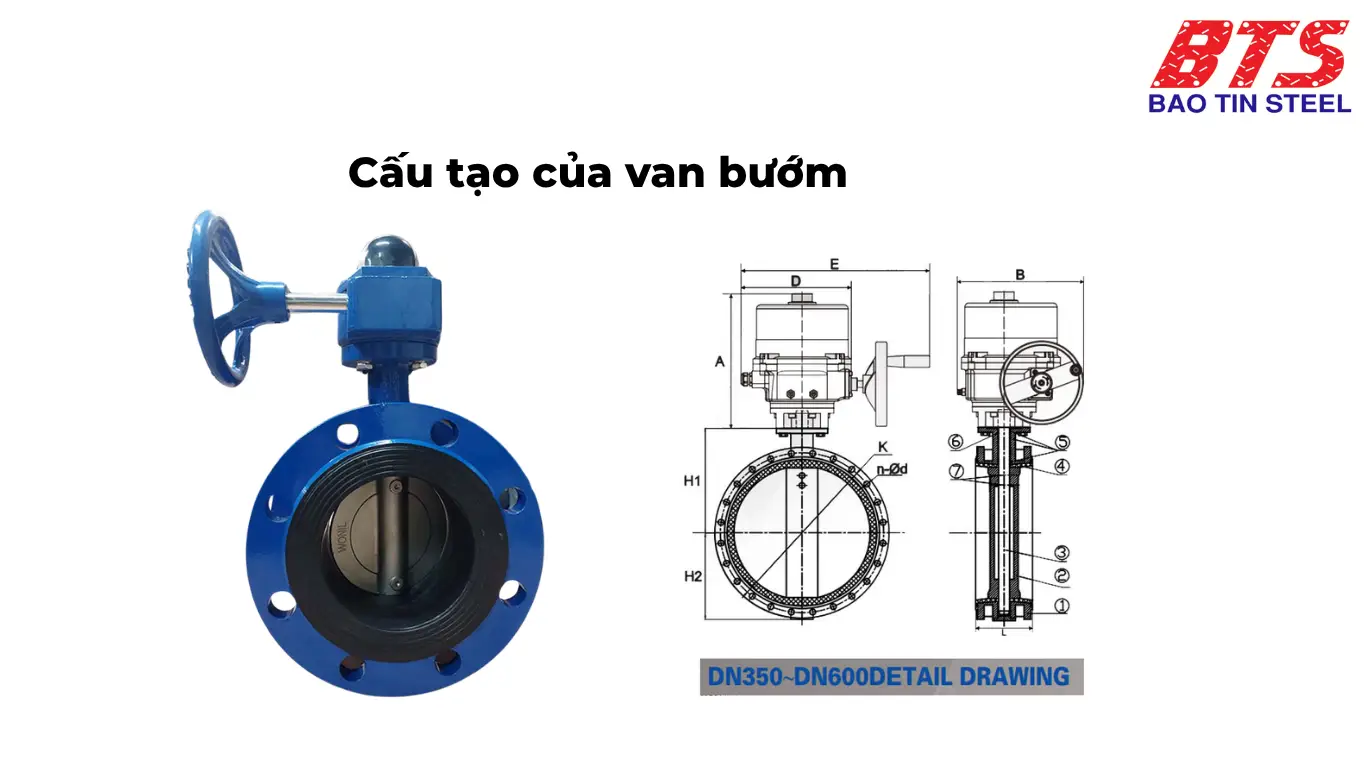

Detailed structure and operating principle.

Structure of the butterfly valve.

A butterfly valve with a monitoring switch includes all the mechanical components of a traditional butterfly valve, with the main parts such as:

- Valve Body: The main structure that protects and stabilises the internal components. It is typically made of ductile iron, stainless steel, or plastic, suitable for environments like clean water, wastewater, chemicals, or fire protection systems (FPC).

- Disc: The component that regulates the flow. It can be designed in concentric, double eccentric, or triple eccentric configurations, depending on the required pressure and temperature specifications. The triple eccentric design provides absolute tight shut-off (bubble-tight shut-off) and reduces friction, making it ideal for heavy industrial environments.

- Shaft: Transfers the force from the actuator to the disc, usually made of stainless steel to ensure resistance to wear and chemical corrosion.

- Seat/Seal: Can be made of EPDM, NBR, PTFE, or metal. The choice of material directly affects the sealing ability and durability in various operating environments.

- Actuator: Can be a handwheel, lever (manual), or electric/pneumatic (automatic). However, in butterfly valves with monitoring switches commonly used in fire protection systems (FPC), a gearbox handwheel is the primary choice.

Structure of the monitoring switch.

The monitoring switch is an electronic component mounted on the outside of the valve gearbox, consisting of:

- Mechanical or magnetic sensor: Detects the movement or position of the valve disc/shaft.

- Electric contact switch (SPDT – Form C): Allows for the NO (Normally Open) or NC (Normally Closed) signal depending on the system design. This is the direct connection point to the SCADA/BMS/FPC control panel.

- Protective housing: Meets IP65 or higher standards or NEMA 4X, ensuring protection against dust, water, impact, and may also be explosion-proof for specialized models.

- Signal wiring: Connects the switch to the control centre. Ensures stable signals and easy wiring.

Overall operating principle

When the operator turns the handwheel (or receives a control signal), the valve disc moves from the closed position to the open position (or vice versa). This movement is mechanically linked directly to the monitoring switch, triggering the switch to change its electrical state:

- When the valve is fully open, the switch sends an “open” signal to the control centre.

- When the valve is closed or tampered with, the “closed” or “tamper” signal is triggered.

- In the case of partial opening (intermediate position), the “abnormal” signal can be configured if needed.

It is important that the switch is precisely calibrated to ensure that even the smallest deviation is detected, especially in systems that require high safety standards, such as fire protection systems (FPC), where an accidental valve closure could lead to a system failure.

Why should butterfly valves with monitoring switches be used?

Here are 6 reasons why this type of valve is widely used in Fire Protection (FPC), HVAC, water supply – water treatment, and automation systems:

- Remote Monitoring – Proactive Control You’ll know if the valve is open, closed, or being tampered with without needing to send someone to check on-site.

- Early Warning – Risk Reduction If the valve is incorrectly closed or tampered with, the switch sends an immediate alert. For fire protection systems, this is crucial—the water supply must always be ready.

- Reduced Maintenance Costs – Increased Efficiency. Instead of waiting for a system breakdown, you can detect abnormalities early and plan proactive maintenance, saving both time and money.

- Compact Design – Easy Installation Butterfly valves are more compact than gate valves, making them easier to install. Even with an integrated switch, you maintain a reasonable investment cost.

- Compliance with Fire Safety Standards: These valves are UL/FM certified and include SPDT switches, fully meeting the requirements of NFPA 13 and NFPA 72.

- Easy Connection to Modern Systems You can easily connect the monitoring switch to BMS, SCADA, fire alarm systems—even smart building IoT applications.

Practical Applications of Butterfly Valves with Monitoring Switches

. With their ability to control flow stably combined with real-time status monitoring, butterfly valves with monitoring switches have become an ideal choice in many industrial and technical infrastructure sectors. Below are their typical applications:

- Fire protection systems (Sprinklers, hydrants, wall-mounted nozzles)

- Water treatment systems (clean water, wastewater, industrial water)

- HVAC – Central air conditioning systems for buildings

- Food, chemical, and metallurgy factories

- Smart buildings, SCADA systems, Industry 4.0 factories

From a mechanical device, the butterfly valve with monitoring switch becomes an important data point, contributing to the overall control system — enabling flexible operation, proactive maintenance, and enhanced overall safety.

Price quote for butterfly valves with monitoring switches 2025.

Factors affecting the price.

The price of butterfly valves with monitoring switches in 2025 depends on many technical and commercial factors, including:

- Nominal Size (DN): DN50 to DN300 are the most common. The larger the size, the higher the price.

- Valve Body and Disc Material: Ductile iron with epoxy coating offers good value; stainless steel and heat-resistant steel are more expensive.

- Monitoring Switch Type: Available with waterproof, explosion-proof casings, or supporting special signals (dual NO/NC).

- Standards and Certifications: UL/FM-certified products are typically 10–25% higher in price than non-certified types.

- Brand and Origin: Valves imported from Korea, Taiwan, and the USA are more expensive than those from China or domestic OEM.

Reference price list 2025 (retail price, excluding VAT).

| Model / Origin | DN50 – DN100 | DN125 – DN200 | DN250 – DN300 | Notes |

|---|---|---|---|---|

| YDK – South Korea (UL/FM) | 1,200,000₫ | 1,700,000₫ | 2,800,000₫ | Handwheel valve, mechanical signal |

| BTL – China (Standard) | 900,000₫ | 1,400,000₫ | 2,300,000₫ | Wafer connection, NO switch |

| AUT – South Korea (UL/FM) | 1,350,000₫ | 1,950,000₫ | 3,200,000₫ | Box-type switch, IP65 |

| Meiji – Taiwan | 1,000,000₫ | 1,600,000₫ | 2,700,000₫ | SPDT contact integrated |

| Wonil – Electric valve + monitoring | 4,000,000₫+ | 5,500,000₫+ |

Note: The prices may vary depending on the order quantity and timing. Please contact Thép Bảo Tín for the most up-to-date price list.

Top 5 common butterfly valve models with monitoring switches.

Currently, there are many butterfly valve models with monitoring switches available in the market, from different brands, suitable for a wide range of applications and budgets. Below are some typical models that are commonly used in fire protection systems, water treatment, and light industries:

1. YDK Butterfly Valve with Monitoring Switch – South Korea

- Model: YDK-VG221

- Size: DN50 – DN300

- Monitoring Switch: SPDT, NO/NC contact

- Standards: UL/FM

- Applications: Sprinkler systems, building fire protection (PCCC)

- Advantages: Durable design, easy-to-operate gearbox, stable signal

2. BTL Butterfly Valve – China

- Model: BTL-VBG-SW Size: DN50 – DN250

- Monitoring Switch: Mechanical lever type

- Standard: Domestic technical standards, basic compliance

- Applications: Domestic water systems, small-scale fire protection (FPC)

- Advantages: Good price, simple installation, suitable for limited budgets

3.AUT Butterfly Valve with Monitoring Switch – Korea

- Model: AUT-VBOS-100

- Sizes: DN50 – DN300

- Switch: Watertight signal box, SPDT dual contacts

- Standards: UL/FM

- Applications: Professional fire protection (FPC), factories, warehouses

- Advantages: High accuracy, durable materials, easy integration with SCADA systems

Meiji Butterfly Valve – Taiwan

- Model: Meiji-VB-TQ

- Size: DN50 – DN200

- Switch: Modular type, customizable for the system

- Standards: ISO, suitable for civil engineering technical standards

- Applications: HVAC systems, water supply and drainage, medium-sized factories

- Advantages: Reasonable cost, lightweight operation, easy maintenance

Meiji Butterfly Valve

Wonil Butterfly Valve with Monitoring Switch

- Model: Wonil-EVBM

- Sizes: DN50 – DN300

- Switch: Integrated valve status feedback

- Standards: UL/FM, depending on the specific model

- Applications: Automated manufacturing plants, smart water supply systems

- Advantages: Remote control, easy connection to SCADA/BMS, simultaneous monitoring & control

Suggestion: If you’re deploying for fire protection (FPC) systems that require mandatory certification, prioritize AUT or YDK models (which are UL/FM certified). For residential applications or low-budget projects, BTL or Meiji models can be optimal choices. Meanwhile, Wonil offers a premium solution for automation systems.

How to Choose the Right Butterfly Valve with Monitoring Switch

Selecting the correct butterfly valve with a monitoring switch will help your system operate efficiently, safely, and reduce maintenance costs. Below are important criteria you should consider before making a decision:

1. Determine the Nominal Size (DN)

Choose the appropriate DN to match the pipe diameter in your system. Common sizes include: DN50, DN65, DN80, DN100, DN150, DN200, up to DN300. In fire protection (FPC) systems, valve sizes typically synchronise with the main water supply riser or sprinkler branch lines.

Lưu ý: Cần xác định rõ áp suất làm việc để chọn đúng cấp áp suất PN10, PN16 hoặc 175/300 PSI

2. Choose Materials Suitable for the Working Environment

| Environment | Recommended Materials |

|---|---|

| Clean water / Fire protection (PCCC) | Ductile iron body with epoxy coating, stainless steel/EPDM disc |

| Wastewater / Mild chemicals | Epoxy-coated cast iron or PVC/PP plastic |

| Hot steam, oil, compressed air | Stainless steel 304/316, alloy steel, metal disc |

| Corrosive chemicals, high temperature | Stainless steel + PTFE gasket/metal |

3.Choose the Appropriate Connection Type

- Wafer: Most common, clamped between two flanges, cost-effective.

- Flanged: Easy to disassemble/assemble, used for high-pressure systems.

- Grooved: Quick connection, convenient for replacement – popular in modern fire protection (FPC).

- Lug: Connects to each pipe end separately, supports detaching individual branches.

4. Evaluate the Type of Monitoring Switch Included

- SPDT Form C: Common, supports both NO (Normally Open) and NC (Normally Closed) contacts.

- Mechanical / Magnetic Sensors: Chosen based on requirements for detailed monitoring or simple signalling.

- Waterproof, Explosion-proof: Necessary in outdoor environments or chemical/oil & gas plants.

Suggestion: Choose a switch that meets IP65/IP67, NEMA 4X, or explosion-proof standards if the system is located outdoors or in hazardous areas.

5. Prioritize UL/FM Certified Products

For Fire Protection (FPC) systems, compliance with standards such as UL (Underwriters Laboratories) and FM (Factory Mutual) is mandatory.

This ensures that the valve functions correctly, maintains proper sealing, and provides accurate signal feedback under emergency conditions.

6. Cân nhắc ngân sách & độ tin cậy lâu dài

- For limited budgets: BTL and Meiji are optimal choices.

- For high-quality requirements, long-term durability, and international standard compliance: Choose AUT, YDK, or Wonil.

- For SCADA/BMS systems: Prioritize valves with monitoring switches that support real-time signal feedback or wireless connectivity.

Bao Tin Steel – A reputable address to buy butterfly valves with monitoring switches

If you are looking for a highly reliable supplier of butterfly valves with monitoring switches, one that fully meets international technical standards and offers on-site technical support, Thép Bảo Tín is a partner you can completely trust.

Why Choose Thép Bảo Tín?

- UL/FM Certified Valves: We supply UL/FM certified butterfly valves, complete with full CO/CQ documentation and verified incoming inspection certificates.

- Partnerships with Leading Brands: We are partners with major brands like YDK, AUT, Wonil, Meiji, and BTL, ensuring products are readily available in stock.

- Competitive Pricing: Benefit from our competitive pricing policies and tender discounts.

- Transparent Warranty & Support: We offer transparent warranties and provide on-site support for installation and signal switch testing according to NFPA standards.

- 13 Years of Experience: With 13 years of experience in supplying industrial valves and fire protection equipment, we have served hundreds of projects, from residential to industrial.

Our Commitment from Bao Tin Steel

- 100% New Products: All items are brand new, with full CO/CQ documentation, and come with a minimum 12-month warranty.

- Same-Day Quotes: We provide price quotes within the same day.

- Full Documentation for Tenders: We supply VAT invoices, contracts, and company profiles for bidding purposes.

- Nationwide Delivery & On-site Support: We offer nationwide delivery and provide on-site support for valve signal testing at your project location.

Conclusion

The butterfly valve with a monitoring switch is not merely a mechanical device; it is a crucial link in the safety monitoring system—especially in fields such as fire protection (FPC), water supply and drainage, HVAC, and industrial plants. Choosing the right type of valve, adhering to the correct standards (UL/FM, NFPA), and matching the precise technical specifications will ensure operational performance, equipment durability, and the ability to respond promptly to risks.

However, to optimize your investment value and avoid risks from substandard products, partnering with a supplier who possesses strong technical knowledge, understands your system requirements, and can provide comprehensive solutions is particularly vital.

Bao Tin Steel – Comprehensive Signal Valve Solutions for Your Technical Systems

Need a quick quote or direct consultation? Call our Hotline now: 0932 059 176!

Tiger Steel is a subsidiary of Bao Tin Steel.

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ