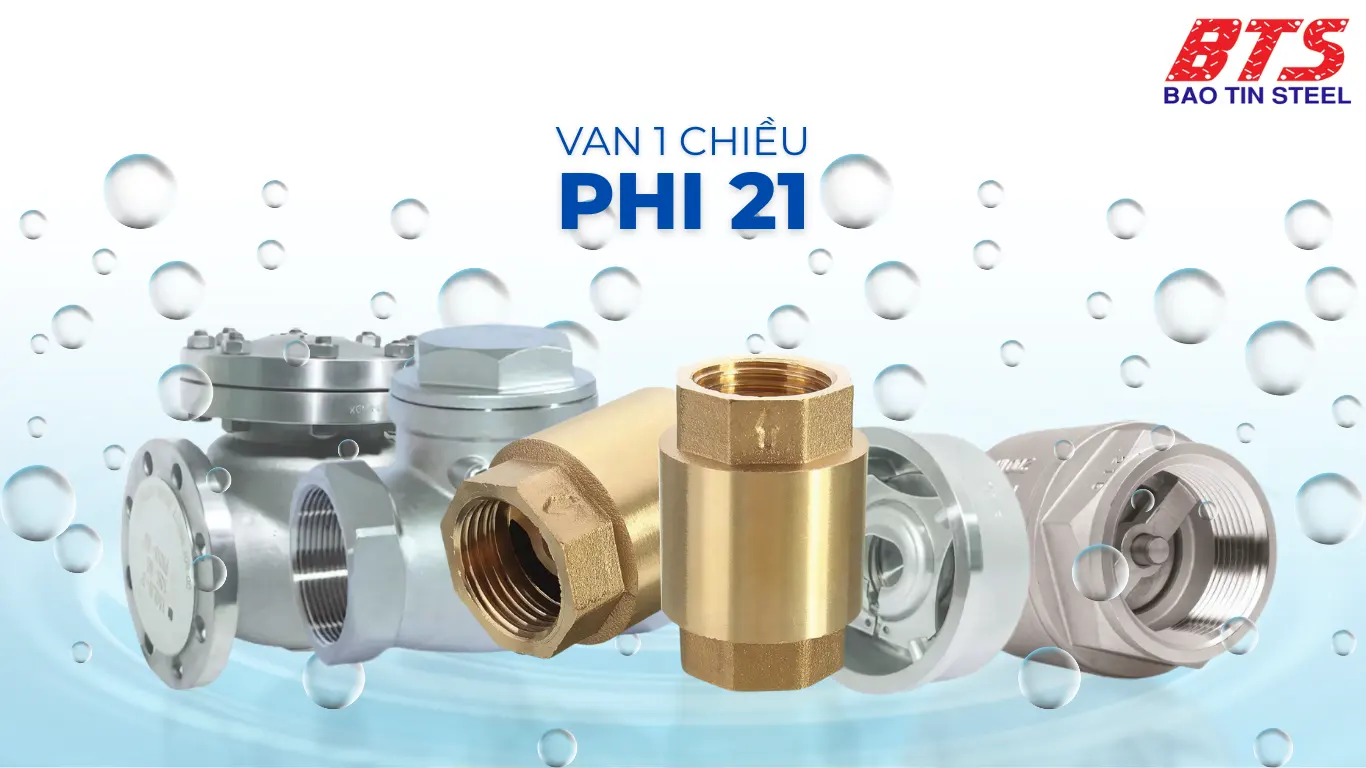

A check valve Ø21 is designed to allow fluid or gas to flow in only one direction, completely preventing backflow that could damage equipment. The product has a nominal size of DN15 (1/2”) with an external thread diameter of approximately Ø21mm, making it widely used in water supply and drainage systems, oil, gas, and firefighting pipelines.

Currently, there are many high-quality 21mm check valve brands on the market, such as Arita and Minh Hòa (MIHA, MBV), offering various connection types and materials suitable for both residential and industrial applications.

Key Features of Check Valve Ø21

Despite its compact size, the DN15 (Ø21mm) check valve delivers excellent performance in protecting piping systems and offers several outstanding advantages:

Key Features of Check Valve 21

Despite its compact size, the DN15 (Ø21mm) check valve delivers excellent performance in protecting piping systems and offers several outstanding advantages:

- Prevents backflow completely: The automatic opening/closing mechanism (spring-loaded or swing disc) protects pumps, pipelines, and terminal equipment from reverse pressure and water hammer.

- Standard dimensions – easy replacement: Ø21mm threaded connection (DN15, 1/2”) fits most residential and industrial systems.

- High-quality materials:

- Brass (Minh Hòa, MIHA, MBV): Durable and corrosion-resistant in clean water environments.

- Stainless steel CF8, CF8M, SS316 (Arita): Superior anti-corrosion for harsh conditions, light oil, or compressed air.

- Premium sealing materials: PTFE, NBR, or VITON gaskets ensure tight sealing, heat and chemical resistance.

- Diverse designs:

- Spring check: Fast closing, prevents hydraulic shock.

- Swing check: Larger flow capacity, low pressure loss.

- Threaded or wafer connections: Flexible installation options.

- Compliant with international standards: ASTM, ASME, JIS, BS, API for reliability and quality assurance.

Technical Specifications

| Parameter | Value |

|---|---|

| Nominal size | DN15 (1/2″) – Ø21mm |

| Connection type | BSP, BSPT, NPT thread or wafer |

| Structure type | Spring check / Swing check |

| Working pressure | 10–20 Bar (150–300 PSI depending on model) |

| Body test pressure | Up to 300 PSI (21 Bar) |

| Working temperature | -10°C to 200°C (depending on material) |

| Body material | Brass (MIHA, MBV) / Stainless steel CF8, CF8M, SS316 (Arita) |

| Disc material | Brass / Stainless steel CF8, CF8M |

| Spring | Stainless steel SS304, SS316 |

| Sealing gasket | NBR, PTFE, or VITON |

| Standards | ASTM, ASME, JIS, BS, API |

| Applicable media | Clean water, light oil, non-corrosive gas |

Practical Applications

Thanks to its standard DN15 size and efficient backflow prevention, the 21mm check valve is widely used in various systems:

- Domestic water supply and drainage: Installed after water meters to prevent reverse flow and stabilise pressure.

- Light oil pipelines: Used in pumping stations or processing plants to ensure safety and prevent product loss.

- Compressed air and clean gas systems: Prevents backflow to compressors, enhancing equipment lifespan.

- Food & beverage processing: Maintains one-way flow in production lines, ensuring hygiene compliance.

- HVAC systems: Prevent reverse circulation in heating and cooling loops.

- Firefighting and wastewater treatment systems: Stabilises flow and protects pumps and critical components.

Economic Benefits for Businesses (Arita & Minh Hòa Valves)

For manufacturers and industrial operators, check valve 21 offers not only technical reliability but also clear economic advantages:

- Reduced maintenance costs: Prevents damage caused by backflow to pumps and valves.

- Extended system lifespan: Protects piping and equipment from abnormal pressure and mechanical wear.

- Optimised efficiency: Maintains steady pressure, minimising fluid loss for continuous operation.

- Lower maintenance frequency: Corrosion-resistant materials reduce service requirements.

- Easy replacement: Standard DN15 threaded design fits existing systems without modification.

- Compliance & safety: Certified to international standards (ASTM, ASME, JIS, BS, API).

Installation and Maintenance Guide

Preparation

- Inspect the valve for cracks or deformation.

- Identify connection type (BSP/BSPT/NPT or wafer).

- Clean pipelines to remove debris or rust.

For Threaded Valves (DN15 – Ø21mm)

- Follow the flow direction indicated by the arrow.

- Apply PTFE tape or sealing compound to male threads.

- Tighten gently with a wrench—avoid over-tightening.

- Ensure proper alignment after installation.

For Wafer Type Valves

- Ensure both flanges are fixed on the pipe.

- Insert a gasket between the valve and flange.

- Align concentrically to prevent misalignment.

- Tighten bolts in a star pattern evenly.

=> See also: Proper Installation Method for Check Valves

Post-Installation Checks

- Test open/close operation with light flow.

- Check for leakage at joints.

- Retighten if necessary.

Maintenance

- Inspect every 3–6 months, depending on operating conditions.

- Clean valve components (disc, spring, gasket).

- Replace worn seals immediately.

- Lightly lubricate metal swing types.

Safety Notes

- Always depressurise and drain the line before disassembly.

- Do not use the valve in highly corrosive media beyond material limits.

- Use only standard-compliant gaskets and fittings for proper sealing.

Supplier Information – Bao Tin Steel

Bao Tin Steel proudly supplies authentic 21mm check valves from reputable brands such as Arita and Minh Hòa (MIHA, MBV), ensuring:

- 100% new products with full CO-CQ certification.

- Competitive pricing and project discounts.

- Nationwide fast delivery and technical support.

📞 Hotline: 0932 059 176

📧 Email: bts@thepbaotin.com

Contact us today for the best quotation and model selection for your system.

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ