The Giacomini φ34 (DN25) check valve is a specially designed product to prevent backflow, ensuring the safety of water supply, heating, and fire protection systems. With multiple versions available, Giacomini offers customers flexible options:

- N5 – a rubber-sealed check valve providing tight sealing and smooth operation.

- N6 – a durable metal-sealed check valve, effectively resistant to wear and tear.

- R60 – a spring-disc check valve featuring low opening pressure, quick response, and suitability for installation in any position.

This variety allows the DN34 check valve to meet stringent technical requirements while optimising operational performance for various types of systems.

Key Features of the φ34 (DN25) Check Valve

When choosing the Giacomini φ34 check valve, users gain numerous outstanding advantages, making it suitable for various types of systems:

Safe backflow prevention: Ensures that the fluid flows in only one direction, protecting pumps, tanks, and other equipment within the system.

Variety of Versions:

- N5 (Rubber Seal): High sealing performance, smooth operation, low pressure loss; suitable for residential and heating systems.

- N6 (Metal Seal): Durable construction, wear-resistant; ideal for high-pressure and high-frequency applications.

- R60 (Spring Disc): Low opening pressure of only 0.02 bar, fast response, installable in any orientation; perfect for systems requiring flexibility.

Premium Materials: Made from CW617N brass body, NBR seals, and AISI 302 stainless steel spring (R60), ensuring long-lasting durability and corrosion resistance.

High Pressure and Temperature Resistance: Operates reliably under pressures of 16–35 bar (depending on version) and temperatures of 5–95 °C, withstanding peaks up to 110 °C.

Easy Maintenance and Cleaning: With removable caps (N5, N6) or a fully detachable valve (R60), inspecting and cleaning the seals and valve disc is quick and convenient.

Technical specifications of Check valve φ34 (DN25

To help you make an informed choice, below is a detailed comparison table of the three versions—N5, N6, and R60—of the φ34 (DN25) check valve:

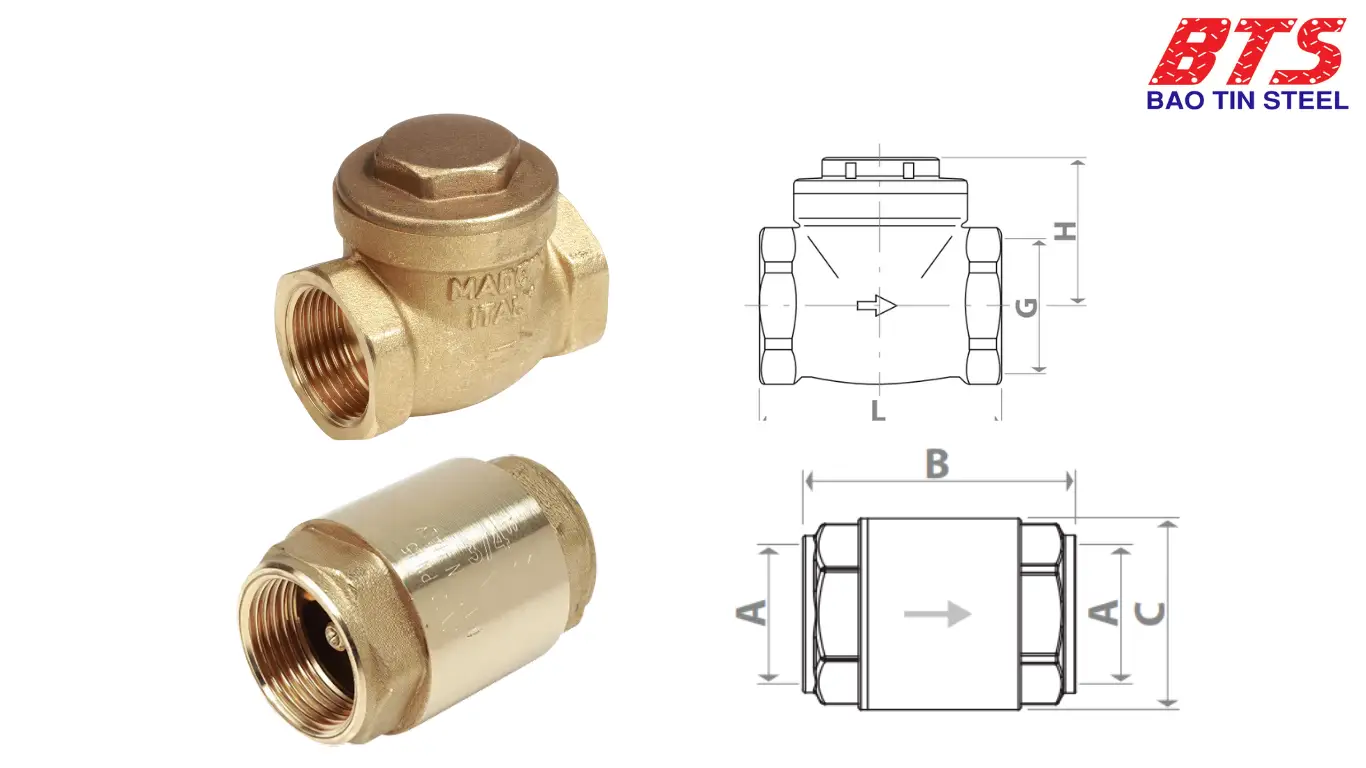

| Specification | N5 – Rubber Seal | N6 – Metal Seal | R60 – Spring Disc |

|---|---|---|---|

| Product Code | N5Y005 | N6Y005 | R60Y005 (POM disc) / R60Y035 (Brass disc) |

| Dimensions | G = 61 mm, H = 61 mm, L = 63 mm | G = 61 mm, H = 61 mm, L = 63 mm | A = 59 mm, B = 44 mm, C = 44 mm |

| Flow Coefficient (Kv) | 17.8 | 17.8 | 10.3 |

| Opening Pressure | 0.05 bar | 0.05 bar | 0.02 bar |

| Max Working Pressure | 16 bar | 16 bar | 16 bar (POM) / 35 bar (Brass disc) |

| Working Temperature | 5–95 °C (peak 110 °C) | 5–95 °C (peak 110 °C) | 5–95 °C (peak 110 °C) |

| Materials | CW617N brass body, NBR seal, brass disc | CW617N/CB753S brass body, NBR O-ring, brass disc | CW617N brass body, NBR seal, AISI 302 stainless steel spring, POM/Brass disc |

| Installation Orientation | Horizontal (cap upward) or vertical (flow upward) | Same as N5 | Installable in any orientation (horizontal, vertical, inclined) |

Practical Applications of the φ34(DN25) Check Valve

The Giacomini DN34 (DN25) check valve is widely used across various fields due to its effective backflow prevention, making it suitable for many types of systems:

- Domestic Water Supply Systems: Prevents contaminated water from flowing back into the main pipeline, keeping the water source safe and clean.

- HVAC and Heating Systems: Maintains stable circulation of the heat transfer fluid (hot water or glycol solution), preventing reverse flow that could cause thermal imbalance.

- Industrial and Agricultural Applications: Protects expansion tanks and piping equipment in high-pressure environments with frequent operation.

- Solar Energy Systems and Boiler Rooms: Ensures one-way circulation of heat transfer fluid, enhancing operational efficiency and prolonging equipment lifespan.

Economic Benefits of Using the φ34 (DN25) Check Valve

Choosing and installing the Giacomini φ34 (DN25) check valve not only ensures system safety but also brings numerous practical economic benefits:

- Extends Equipment Lifespan: Preventing backflow reduces vibrations and hydraulic shocks, minimising damage to pumps, expansion tanks, and other equipment.

- Reduces Maintenance and Repair Costs: Controlled flow decreases the risk of leaks and breakdowns, saving on routine maintenance expenses.

- Optimises System Performance: N5 and N6 versions feature high Kv values for smooth fluid flow, while the R60 has low opening pressure and fast response, ensuring efficient and energy-saving system operation.

- Flexible and Efficient Investment: Users can choose the most suitable type—N5 for standard applications, N6 for durability in harsh environments, or R60 for high-end performance with flexible installation and high-pressure tolerance.

- Increases Project Reliability: With European-standard design and consistent quality, the DN34 check valve ensures long-term safe operation and reduces the risk of system interruptions.

Installation & Maintenance Guide for the φ34 (DN25) Check Valve

To ensure efficient and long-lasting operation of the Giacomini φ34 (DN25) check valve, users should follow proper installation and maintenance procedures:

Installation Instructions

For N5 & N6 (Swing Check Valve):

- Install the valve following the direction of the arrow marked on the body.

- Horizontal installation: The valve cover must face upward; incorrect orientation will prevent proper operation.

- Vertical installation: The valve will only operate correctly if the flow moves from bottom to top

For R60 (Spring Disc Check Valve):

- It can be installed in any orientation (horizontal, vertical, or inclined), as long as the flow direction is respected.

- Suitable for systems with limited space or complex layouts.

=> See more: Instructions on how to install a Check valve properly

Maintenance Instructions

Periodic Inspection:

Perform regular checks depending on usage frequency and operating environment.

For N5 & N6:

- If signs of leakage appear, open the inspection cap on the valve body to clean the disc and rubber seal.

- Remove dirt and debris using compressed air or mechanical cleaning.

For R60:

- In case of leakage, remove the entire valve from the system to clean the seal and spring.

- Always relieve pressure and shut off the fluid supply before disassembly to ensure operator safety.

The above provides an overview of the Giacomini φ34 (DN25) check valve. If you are looking for a high-quality, genuine check valve at a competitive price, contact Bao Tin Steel today for a detailed consultation and a special quotation.

- Hotline: 0932 059 176

- Email: bts@thepbaotin.com

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ