Are you looking for a high-quality DN100 (φ114) check valve that meets strict technical standards for your piping system?

This valve is specially designed to prevent backflow, protect pumps and equipment, and maintain stable pressure. With a φ114 (DN100) size, it is suitable for a wide range of applications, including water supply and drainage, fire protection (PCCC), HVAC, and processing industries.

At Bao Tin Steel, we offer a full range of φ114 check valve models from reputable brands such as Shin Yi, ROBO, and ARV, with full CO-CQ certification, clear origin, ready stock, and competitive pricing. This article will help you understand the features, specifications, pricing, and installation guidance to choose the optimal product.

Key Features of DN100 (φ114) Check Valves

DN100 check valves are designed for stable operation, durability, and easy maintenance, meeting technical requirements in various working environments. Key highlights include:

- Effective backflow prevention: Automatic opening and closing mechanism protects pumps, pipes, and downstream equipment from reverse flow and back pressure.

- Quick operation, reduces water hammer: Swing, spring, or dual-plate designs reduce hydraulic shocks, ensuring system safety.

- Durable materials: Valve bodies are usually made of ductile iron (EN-GJS-500), with stainless steel or EPDM-coated discs, offering corrosion resistance and high pressure/temperature tolerance.

- Multiple connection types: Options include flanged, wafer, or threaded connections per JIS, DIN, BS, or ASME standards.

- Easy maintenance: Removable valve covers allow for simple cleaning and component replacement.

- Wide system compatibility: Suitable for water supply/drainage, PCCC, HVAC, and processing industries.

DN100 (φ114) Check Valve Models

DN100 (φ114) Check Valve Models

DN100 (φ114) Check Valve Models

| Brand | Model / Type | Size (DN) | Working Pressure | Working Temp | Body Material | Disc Material | Design Standard | Connection Standard |

|---|---|---|---|---|---|---|---|---|

| Shin Yi | RDCV – Swing | DN100 (φ114) | PN10 / PN16 | -10 ~ 80°C | Ductile Iron EN-GJS-500-7 | EPDM-coated steel | BS EN 1074-3 | JIS B2220, DIN 2632/2633, BS 4504 |

| Shin Yi | SCVX – Spring | DN100 (φ114) | PN10 / PN16 / PN25 | -10 ~ 80°C | Ductile Iron EN-GJS-500-7 | Iron + EPDM | BS EN 1074-3 | JIS B2220, DIN 2632/2633, BS 4504 |

| Shin Yi | WBCX – Dual Plate | DN100 (φ114) | PN10 / PN16 / PN25 | -10 ~ 80°C | Ductile Iron EN-GJS-500-7 | Stainless Steel CF8/CF8M | API 594 | JIS B2220, DIN 2632/2633, BS 4504 |

| ROBO | DCV – Swing | DN100 (φ114) | PN10 / PN16 | -10 ~ 80°C | Ductile Iron ASTM A536 | EPDM-coated steel | BS EN 1074-3 | JIS B2220, DIN 2632/2633, BS 4504 |

| ROBO | SCV – Spring | DN100 (φ114) | PN10 / PN16 | -10 ~ 80°C | Ductile Iron ASTM A536 | Iron + EPDM | BS EN 1074-3 | JIS B2220, DIN 2632/2633, BS 4504 |

| ARV | AFC200 – Swing Check | DN100 (φ114) | PN16 | ≤ 80°C | Ductile Iron EN-GJS-500 | NBR / EPDM | EN 12234 / EN 16767 | EN 1092-2, ISO 7005-2 |

Notes:

- All products have epoxy coating (250–300 µm) for corrosion protection.

- Sizes and specs may vary depending on project requirements and connection standards.

Types of DN100 Check Valves at Thép Bảo Tín

-

Swing Check Valves (Rubber Disc Check)

-

Brands: Shin Yi (RDCV), ROBO (DCV), ARV (AFC200)

-

Features: 45° swing, quick closure, reduces water hammer, EPDM-coated disc

-

Advantages: Simple design, high flow, cost-effective, easy maintenance

-

Applications: Water supply/drainage, PCCC, light industrial systems

-

-

Spring Check Valves (Silent Check)

-

Brands: Shin Yi (SCVX), ROBO (SCV)

-

Features: Stainless steel spring ensures quiet, fast closure, reduces noise and water hammer

-

Advantages: Closes effectively at low pressure, ideal for noise-sensitive systems

-

Applications: Pump systems, HVAC, high-rise buildings, residential areas

-

-

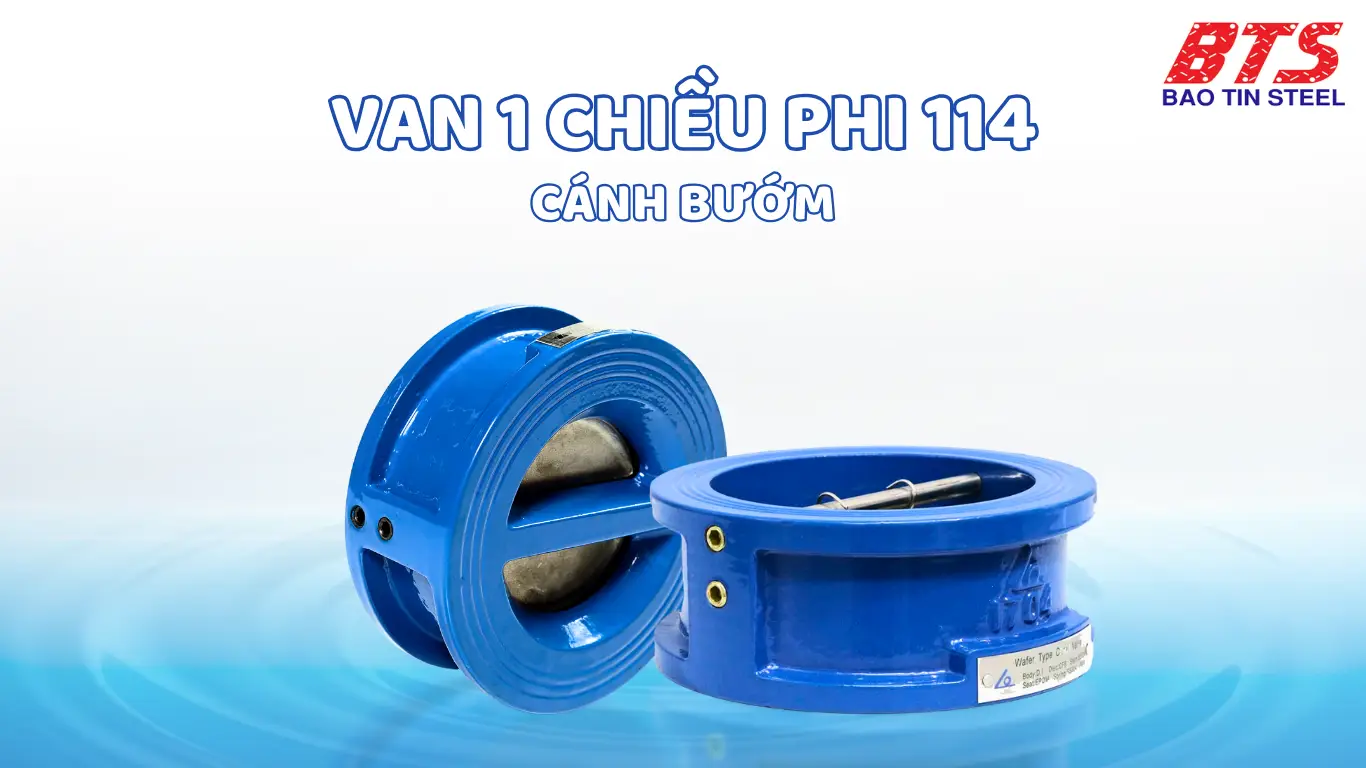

Dual Plate / Wafer Check Valves

-

Brand: Shin Yi (WBCX)

-

Features: Ductile iron body, stainless steel discs, compact wafer design

-

Advantages: Lightweight, easy to install in tight spaces

-

Applications: Clean water pumps, light processing industries

-

swing check valve

swing check valve

Advantages of Purchasing from Thép Bảo Tín

- Ready stock for all models and brands

- Full CO-CQ certification for origin and quality

- Technical support and warranty

- Wide applications: water supply, PCCC, HVAC, industrial processing

Spring check valve

Spring check valve

Applications of DN100 Check Valves

- Water supply and drainage in water treatment plants and urban systems

- Fire protection (PCCC) systems in industrial buildings

- HVAC systems and light industries

- Wastewater treatment and environmental systems

- Oil, gas, and chemical processing

Butterfly check valve

Butterfly check valve

Tips for Choosing DN100 Check Valves

-

Determine working environment:

-

Clean water / PCCC: Swing or spring valves with EPDM discs

-

Wastewater/debris: Swing valves with wider cavities

-

Light chemicals: Stainless steel or corrosion-resistant discs

-

-

Select connection type:

-

Flanged: Better sealing, easy maintenance

-

Wafer: Compact, ideal for limited space

-

-

Determine working pressure: PN10, PN16, PN25 based on system needs

-

Compare brands:

-

Shin Yi: Versatile, stable quality

-

ROBO: Competitive price, compact, easy maintenance

-

ARV: High durability, heavy-duty industrial use

-

-

Buy from reliable suppliers: CO-CQ, warranty, and technical support are essential

Installation & Maintenance Guidelines

Preparation:

- Check valve size, connection standard, and flow direction

- Clean contact surfaces

- Prepare correct gaskets (EPDM/PTFE) and bolts

Installation Steps:

-

Confirm flow direction using the arrow on the valve body

-

Position valve:

-

Flanged: Centre between two flanges

-

Wafer: Align straight if horizontal

-

-

Install gaskets

-

Tighten bolts symmetrically in a star pattern

-

Test operation

Maintenance:

- Check every 3–6 months, depending on the environment

- Clean disc and sealing surfaces

- Replace the spring if worn

- Recoat the surface if the epoxy is damaged

- Avoid strong corrosive chemicals

Tip: Combine check valves with pressure gauges and isolation valves for easier maintenance in water supply and PCCC systems.

Buy Genuine DN100 Check Valves at Bao Tin Steel

Why choose Bao Tin Steel?

- 100% genuine products from Shin Yi, ROBO, ARV

- Full CO-CQ certification

- Ready stock for fast project delivery

- Competitive pricing with bulk discounts

- On-site technical support and installation guidance

- Nationwide delivery

Contact Bao Tin steel: Hotline: 0932 059 176 or visit thepbaotin.com for the latest DN100 check valve pricing and free technical consultation.

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ