In water supply systems, compressed air, steam, or chemicals, the stainless steel ball valve with lever handle is always the preferred choice. This is due to its high durability, quick open/close capability, and effective corrosion resistance. This type of valve operates simply by rotating the lever handle 1/4 turn, allowing for fast and precise flow control. Not only is it widely used in residential applications, but it is also commonly found in food processing plants, industrial zones, water treatment stations, and even fire protection systems (PCCC).

So, what are the outstanding features of the stainless steel ball valve with lever handle? Which type should be selected to match the system? And what is the current price list? Let’s explore these details with Thép Bảo Tín in the article below.

What is a stainless steel ball valve with a lever handle?

A stainless steel ball valve (in English, Ball Valve) is an industrial valve used to open/close the flow in pipelines through a simple mechanism: rotating the lever handle by 1/4 turn (90 degrees). Inside the valve is a hollow ball with a through hole. When the lever handle is rotated, the ball also rotates, allowing the fluid to either pass through or be completely blocked.

The standout feature of this type of valve is that its body is made from stainless steel, with the most common materials being 304 stainless steel and 316 stainless steel. Among these:

-

304 stainless steel is suitable for environments with clean water, compressed air, and mild steam.

-

316 stainless steel offers better corrosion resistance. It is especially suitable for environments with chemicals, seawater, or harsh conditions.

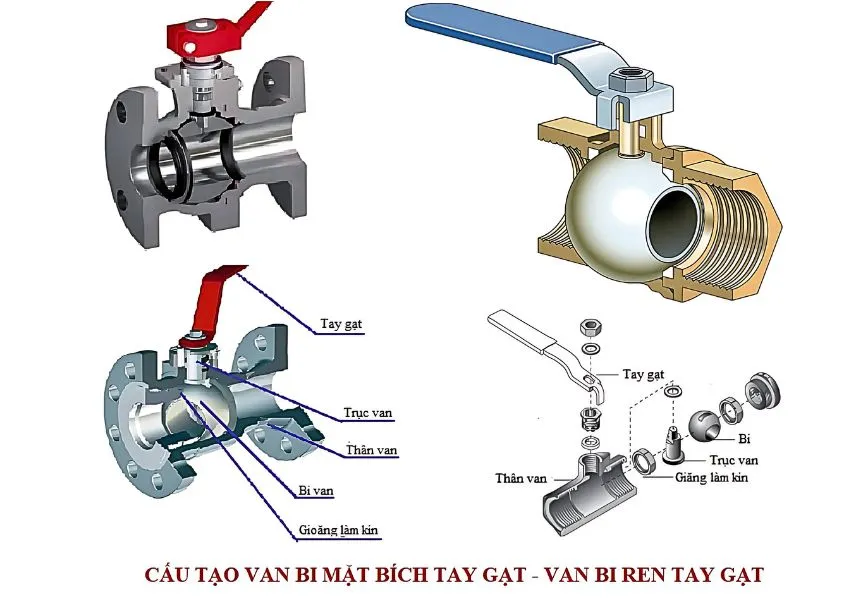

Structure and Operating Principle of Stainless Steel Ball Valve with Lever Handle

Basic Structure:

–

Valve Body: The main part that houses other components and connects to the pipeline. Made from stainless steel materials such as SUS 304, SUS 316, or SUS 201, ensuring excellent corrosion resistance. The body can have threaded, flanged, or welded connections.

Ball: The key component for opening and closing the flow. It’s a hollow, spherical shape with a through hole, made from stainless steel and polished to reduce friction. The ball aligns with the flow when open and rotates 90 degrees to block it when closed.

Valve Stem: Connects the lever handle to the ball and transmits rotational movement. Made from durable stainless steel, with grooves or edges to attach the handle.

Seals/Seats: Placed between the ball and the valve body, ensuring a tight seal to prevent leakage. Typically made of Teflon (PTFE) or other heat- and chemical-resistant materials.

Handle/Lever: Used to operate the valve. Rotating the handle 90 degrees rotates the ball, switching the valve between open and closed. The handle is often coated with plastic or rubber for a better grip.

Body Seals/Gaskets: Placed between the valve body parts (in two- or three-piece designs) to ensure tight sealing and prevent leakage from joints.

Operating Principle

When you rotate the lever handle, the valve stem turns, causing the ball inside to rotate by 90 degrees. If the hole in the ball is aligned with the pipeline, the valve will be fully open, allowing the flow to pass through.

When the ball rotates perpendicular to the pipeline, the hole is blocked by the seals, and the valve will be fully closed, preventing the flow.

👉👉 Let’s take a look at the stainless steel ball valves with lever handles distributed by Bao Tin Steel:

Classification of Stainless Steel Ball Valve Lever Handles and Applications

Stainless Steel Ball Valves with Lever Handles are classified according to various criteria, making it easier for users to choose the type that best suits specific applications. Below are the common classification methods:

This is the most common classification method based on the number of pieces that make up the valve body:

Stainless Steel Ball Valve with Lever Handle, One-Piece Body

The valve body is cast as a single, seamless piece. It has a simple, compact design and is usually the most affordable. However, users may face difficulties in maintaining, repairing, or replacing internal components (such as the ball or seals) because it cannot be disassembled. When damaged, the entire valve often needs to be replaced. This type is typically used in small piping systems with minimal maintenance needs, or where absolute sealing is required and disassembly is not allowed.

Stainless Steel Ball Valve with Lever Handle, Two-Piece Body

The valve body consists of two parts connected by bolts or threads. This valve is easier to disassemble, maintain, and repair compared to the one-piece type. However, there is a potential risk of leakage at the body joint if not properly installed or sealed. It is common in many industrial and residential systems and is suitable for medium-sized piping systems.

Stainless Steel Ball Valve with Lever Handle, Three-Piece Body

The valve body is divided into three parts (two end connections and one central body housing the ball), which are connected by bolts. This design allows for the easy removal of the central part (containing the ball and stem) from the pipeline without needing to remove the entire valve. This feature makes maintenance, cleaning, or seal replacement very convenient and quick. It also handles high pressure better. However, it is typically more expensive than the one-piece and two-piece types. It is commonly used in systems that require frequent maintenance, harsh environments, or where durability and longevity are essential, such as in the chemical, food, or pharmaceutical industries.

Classification by Connection Type with Pipeline

Stainless Steel Ball Valve with Threaded Connection

This valve has threads at both ends to directly connect to the pipeline by screwing. The installation is simple, quick, and does not require any special tools. However, it is only suitable for small pipelines (usually up to DN50). It can leak if the thread sealing tape or sealant is not properly applied, and it is difficult to disassemble for maintenance on larger pipelines. This type is commonly used in residential water systems, compressed air systems, and small industrial pipelines.

Stainless Steel Ball Valve with Flanged Connection

This valve features flanges at both ends, which are bolted to the flanges on the pipeline. This ensures a secure and reliable connection and allows for easy disassembly for maintenance or valve replacement without the need to cut the pipe. It is suitable for larger pipelines and high-pressure systems. However, this type tends to be larger, making it more expensive, and requires sealing gaskets between the flanges.

It is commonly used in large industrial pipeline systems, chemicals, oil and gas, and steam systems, where high safety and stability are required.

Stainless Steel Ball Valve with Welded Connection

The valve ends are designed to be welded directly to the pipeline, creating a permanent, airtight seal that can withstand very high pressure and temperature, with no risk of leakage at the connection. However, installation of this valve requires professional welding skills, and it is difficult to disassemble for maintenance or replacement (requiring pipe cutting).

This type is typically used in high-pressure and high-temperature systems, gas pipelines, hazardous chemicals, or areas requiring absolute safety and limited space.

Classification by Stainless Steel Material

SUS201 Stainless Steel: Has moderate corrosion resistance and pressure tolerance, and is more affordable. It is suitable for clean water environments and non-corrosive conditions.

SUS304 Stainless Steel: The most common material, it offers good corrosion resistance in many environments and can withstand moderate heat and pressure. It is ideal for water, air, light chemicals, and food applications (not highly specialised).

SUS316 Stainless Steel: Offers superior corrosion resistance, especially in environments containing chlorides (saltwater, strong corrosive chemicals). It is commonly used in the chemical, oil and gas, maritime, medical, and high-demand food industries.

General Specifications of Stainless Steel Ball Valves with Lever Handle

Below are the general technical specifications of stainless steel ball valves with lever handles:

- Common Sizes: From DN15 – DN200

- Materials: SUS304, SUS316, SUS201

- Operating Environment: Oil, gas, air, water

- Connection Types: Welded, threaded, flanged

- Temperature: From 0°C to 250°C

- Allowable Pressure: From PN16 to PN65

- Origin: Vietnam, South Korea, China, Taiwan, Japan, Europe

Reference Price List for Stainless Steel Ball Valves with Lever Handle

Depending on the brand, specifications, and connection type, the prices of stainless steel ball valves with lever handles can vary.

Below is the REFERENCE PRICE LIST for stainless steel ball valves with lever handles. Please note that these prices are not fixed and may change depending on the timing. To get the most accurate quote, please contact Thép Bảo Tín for immediate assistance:

| Size | Price of Stainless Steel Ball Valve with Lever Handle SUS304 (VND/piece) | Price of Stainless Steel Ball Valve with Lever Handle SUS304, Flanged Connection (VND/Each) |

| DN15 | 174.000 | 1.182.000 |

| DN20 | 238.800 | 1.440.000 |

| DN25 | 342.000 | 1.716.000 |

| DN32 | 528.000 | 2.118.000 |

| DN40 | 692.400 | 2.700.000 |

| DN50 | 1.020.000 | 3.036.000 |

| DN65 | Contact | 4.032.000 |

| DN80 | Contact | 5.820.000 |

| DN100 | Contact | 7.674.000 |

| DN125 | Contact | 10.440.000 |

| DN150 | Contact | 14.868.000 |

| DN200 | Contact | 24.948.000 |

Conclusion

If you are looking for a place to purchase high-quality stainless steel ball valves with lever handles, complete documentation, and delivery to your location, Bao Tin Steel is a top choice for you. With over 13 years of operation, industrial valves are one of the company’s main products. When purchasing ball valves at Bao Tin Steel, you can be assured of:

-

Genuine, brand-new products, 100% new

-

Valves come with full inspection documents and quality certificates

-

A wide variety of specifications and designs

-

Super competitive prices

-

Stock available in Ho Chi Minh City, Bac Ninh, and Cambodia. Customers can visit the warehouse directly to purchase products.

Above are the most basic details about stainless steel ball valves with lever handles. If you have any further questions, feel free to contact Bao Tin Steel for assistance – Hotline: 0932 059 176!

Tiger Steel is a subsidiary of Bao Tin Steel.

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ