What is a check valve?

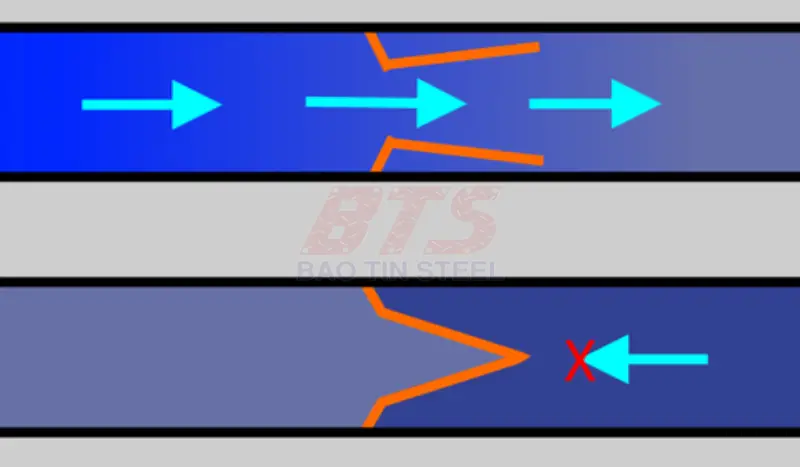

As far as I know, a check valve is called a one-way valve. An industrial valve product is opened by liquid-gas flow in one direction, and the valve disc closes automatically when the flow stops or reverses.

Check valves can operate automatically only for liquid or gas pressure. And most are not controlled by humans or any external control devices.

Therefore, it is quite a popular protective device in pipeline systems. It especially protects hydraulic circuit equipment such as pipes, pumps, tanks, etc.

I almost forgot it again. You need to pay attention to an extremely important factor when choosing a check valve.

⇒ These are the cracking pressure and the sealing pressure.

- Cracking pressure refers to the minimum, required pressure differential between the inlet and outlet of a valve while the valve is open. There, the first signs of fluid appeared.

Cracking pressure is also known as unsteady pressure or opening pressure. Typically, check valves are designed and specified for a specific cracking pressure.

In contrast to cracking pressure, there is welding pressure.

- Sealing pressure refers to the pressure difference between the inlet and outlet of the valve during the closing of the check valve. There was no visible leakage rate.

The definition of a one-way valve is just that.

⇒ Learn more: Solenoid valves

Common check valve classification

There are many different types of check valves, designed to suit different applications. There are four common types of one-way valves, such as:

- Swing check valve

- Check valve.

- Membrane check valve

- Butterfly check valve

- Spring check valve

Different types of check valves have different advantages and limitations. So when choosing a valve, you should consider the specific requirements of your system and the characteristics of each valve type.

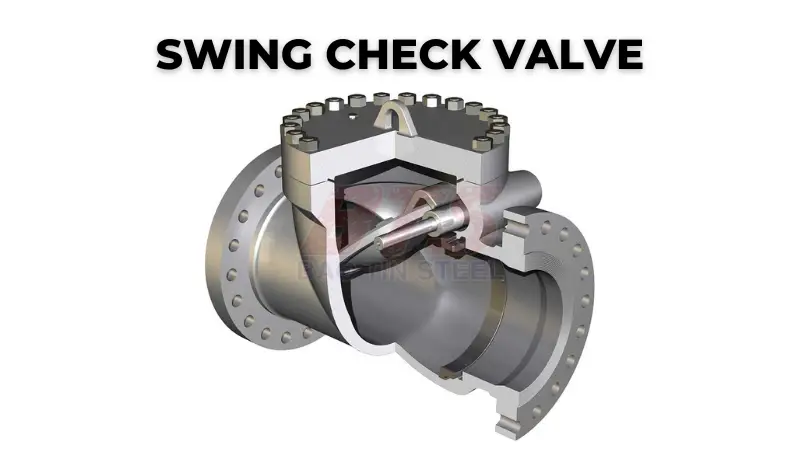

What is a Swing Check Valve?

The swing check valve is a line of rotating disc one-way valves (leaf-shaped check valve or swing-door check valve). The valve’s structure includes:

- Valve body

- Bonnet

- A disc is connected to a hinge or shaft.

When the fluid passes through the valve in one direction, it will press the valve disc and push the valve disc away from its original position. When the fluid flow reverses or stops, the fluid no longer acts on the valve disc. And it returns to its original position.

The cross-section of the base can be perpendicular to the center line between the two ports or at an angle.

Advantages of Swing Check Valve:

- The valve allows full, unobstructed flow and automatically closes when pressure drops.

- These valves are completely closed when the flow in the pipeline reaches zero to prevent reverse flow.

- The turbulence and pressure drop in the valve are very low.

- The weight of the valve disc is light.

Disadvantages of swing check valve:

- The disc in a rotary disc check valve is not guided when it is fully open or closed.

- Rotary disc check valves often cause the water hammer phenomenon, an extremely dangerous phenomenon in pipelines.

⇒ See more: What is Valve?

What is Lift Check Valve?

A lift check valve is a check valve with a servo element. It has a valve disc design similar in structure to a globe valve, and the disc is usually in the form of a piston or ball.

Check valves with booster elements are especially suitable for applications with high pressure or pipelines with high flow velocities.

The flow that causes the check valve disc to open must always enter below the valve seat.

Operating principle:

When flow enters, the piston or ball valve, under the effect of thrust, is lifted. When the flow stops or reverses, the piston or valve ball is forced against the valve seat by both reverse flow and gravity.

Advantages of check valves with servo elements:

- The valve disc is precisely guided and fits perfectly into the control unit.

- These valves are completely closed when the flow in the pipeline reaches zero to prevent reverse flow.

- The turbulence and pressure drop in the valve are very low.

- The check valve with servo element is suitable for installation in horizontal or vertical pipelines with upward flow.

Disadvantages of check valve with servo element:

- The check valve has a booster element that can easily become clogged if the required liquid is not filtered thoroughly.

Lift check valves can be designed in many different designs and sizes. To suit the specific requirements of different applications. However, all types of lift check valves have the same purpose of controlling flow and preventing backflow in the pipeline system.

Stop-check valve

A stop-check valve is a check valve with an override control that stops flow regardless of flow direction or pressure.

That means whether the fluid flows forward or backward, the pressure in the pipe is high or low. The stop valve can be opened and closed intentionally by an external mechanism. Therefore, the valve automatically prevents any flow, regardless of the front pressure, from entering the valve and system.

Membrane check valve

The membrane check valve uses a flex rubber diaphragm positioned to create a normally closed valve.

The reason it is called a membrane check valve is because the valve disc is designed with a plastic or rubber membrane between two valve plates.

The valve opens and closes according to the principle:

As fluid flows through the valve, pressure pushes the membrane away from the previous valve plate and allows the fluid to move to the next pipe. When the pressure decreases or reverses, the membrane will automatically return to its original position to prevent the fluid from flowing backward.

For the membrane check valve to open, the pressure on the upstream side must be greater than the pressure on the downstream side by a certain amount, called the pressure difference.

When the positive pressure stops, the diaphragm will automatically bend back to its original closed position. This type is used in respirators (masks) with exhalation valves.

Inline check valve

Duckbill valve

A duckbill valve is a check valve manufactured from rubber or synthetic elastomers. The valve has two (or more) flaps, shaped like a duckbill. It is commonly used in medical applications to prevent contamination due to backflow.

You can see the image below to better understand how this valve operates.

Reed valve

A reed valve is a type of check valve that restricts the flow of fluid in a single direction. The valve disc will open and close under varying pressure on each side. Modern versions often consist of flexible metal or composite materials (fiberglass or carbon fiber).

Advantages of reed valve:

- Cracking pressure is very low.

- Low-mass moving parts enable fast operation.

- Moderate flow resistance and improved sealing with back pressure.

- Some reed valves have an additional mechanism to selectively open the valve to establish a flow path.

Disadvantages of reed valves:

- Making a reed valve depends greatly on its actual application, and needs to be carefully calculated from many factors.

Structure of check valve

- Swing check valve

- Lift check valve

First, let’s learn about the structure of a rotating disc check valve.

Structure of swing check valve

The structure of the swing check valve includes the following components:

- Valve body: The valve body is usually made of cast steel or stainless steel and has a main circular hole to allow the flow of liquid or gas to pass through.

- Valve layer: The valve layer is usually made of heat-resistant and corrosion-resistant materials such as stainless steel or brass. The valve layer is attached to the central axis of the pipeline and can rotate around this axis to open or close.

- Valve stem: The valve stem is the component between the valve layer and the valve body and is used to rotate the valve layer to open or close.

- Gasket: The valve gasket is an impact-resistant part that holds the valve layer tightly against the valve body when the valve layer closes to prevent backflow.

- Suspension: Suspension is used to hold the valve in a closed position when there is no flow of liquid or gas.

Depending on the specific application, swing check valves can be designed in different sizes and materials to meet the requirements of the duct system.

Structure of lift check valve

The structure of the lift check valve includes the following components:

- Valve body: usually made of cast steel or stainless steel. And there is a main round hole to let the liquid or gas flow through.

- Valve layer: usually made of heat-resistant and corrosion-resistant materials such as stainless steel or brass. The conical valve layer is attached to the central axis of the pipe and moves up and down vertically to control the flow. The valve bed is often designed with a rubber or flexible metal gasket between the top of the valve bed and the ceiling of the valve body, which reduces thrust and noise when the valve bed closes.

-

Valve shaft: The valve shaft is the component between the valve layer and the valve body. And used to move the valve layer up and down to control the flow. The valve stem is usually fastened to the valve bed and may be designed with one or more flexible rubber or metal gaskets to reduce thrust and noise when the valve bed closes.

-

Valve seat: The seal seat is an impact-resistant part that holds the valve seat tightly against the valve body when the valve seat closes to prevent backflow. Valve seats are typically made of hard metal, such as stainless steel or brass, and can be ground to ensure tightness and durability.

-

Spring: The spring is used to push the valve bottom up and keep the valve bottom and valve stem in contact with the valve seat to prevent backflow. The spring is usually made of stainless steel or brass and is located below the valve layer.

Applications of check valves

Check valves are used with some pumps. They look like small cylinders attached to the inlet and outlet ends of the pump.

Check valves are also used in many liquid transport systems. As in chemical and energy plants, and in many other industrial processes.

Check valves are also commonly used when mixing multiple gases into one gas stream. A check valve is installed on each gas line. To avoid mixing gases at the source.

Check valves are also used in domestic applications. To prevent contaminated water from re-entering the domestic water supply.

Some sprinklers and drip irrigation systems have small one-way valves built into them to keep the pipes from draining when the system is turned off.

Check valves are used in heating systems to prevent vertical convection. Especially in combination with solar thermal installations, also known as gravity brakes.

Check valves are commonly used in inflatables, such as toys, mattresses, and boats. They allow the object to be inflated without constant or uninterrupted air pressure.

Above is some information about check valves and their operating principles. Follow thepbaotin.com to receive more useful knowledge!

Cite the source of the images used in the article:

Photo source: Cameron International Corporation and Wikipedia

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ