FKK is a reputable welding fitting manufacturing brand from Japan. The products at FKK are not only quality but also highly applicable. Let’s find out the latest FKK accessories catalog and the distribution address of genuine and reputable FKK fittings in Vietnam.

Introducing the FKK brand

FKK is the abbreviation of Furubayashi Industrial Equipment Co., Ltd. The company was officially established in the 8th year of Taisho (1919), headquartered at 3-3-17 Tsumori, Nishinari, Osaka, Japan.

In 2014, FKK decided to establish its first subsidiary in Vietnam. FKK Vietnam Company Limited is headquartered in Duc Hoa, Long An, Vietnam. Here, we specialize in producing long elbow, short elbow, regular, and concentric reducers, eccentric reducers, and caps (black and galvanized).

By equipping a series of modern machines, FKK has owned a production system that has achieved international quality certificates such as JIS (Japanese Industrial Standard) and ISO 9001 Quality Certification, along with many other prestigious certificates. This is the basis for helping customers feel secure when choosing products from this brand.

Certified standard of FKK welding fittings

JIS product certification

On April 3, 2018, the Japanese quality assurance organization, Japan Quality Assurance Organization (JQA), issued the JIS B2311 Japanese Industrial Standard Certificate for the products of FKK Vietnam Company.

ISO 9001 certification

On August 10, 2018, the Japan Quality Assurance Organization (JQA) Standards Association issued ISO 9001:2015/JIS Q9001:2015 certification to FKK Vietnam Company.

Quatest 3 certification

In addition to the above two certifications, FKK Vietnam Company also received a 3-level Quatest 3 (KT3) and 07039CK6/4 certificate from the General Department of Standards, Metrology, and Quality—Technical Center for Quality Measurement Standards—on July 1, 2016.

Catalog of FKK welding fittings

FKK product catalog

The FKK Vietnam company currently produces the following welding fittings (black):

- Welding Elbow is 90° long

- Welding elbow is 45° long

- Welding Elbow is 90°N long

- Eccentric Reducer and Concentric reducer

- Welded cap

- Tee and Tee reduced

In addition, FKK also produces welding fittings using the hot-dip galvanizing processing method. Hot-dip galvanized fittings are mainly used to carry water for firefighting, water (in food), gas, oil, etc.

FKK welding fittings production standards

Below are some standards for manufacturing welding fittings of the FKK brand:

| JIS B2311 | Steel Butt-Welding Pipe Fittings for Ordinary Use Carbon Steel |

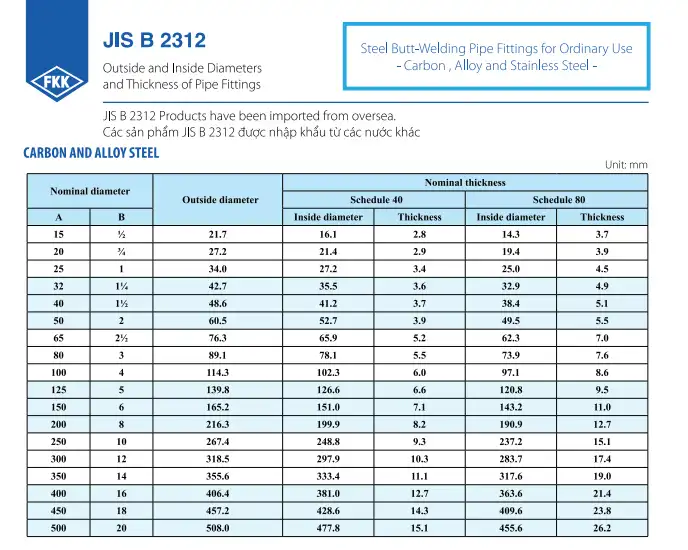

| JIS B2312 | Steel Butt-Welding Pipe Fittings for Ordinary Use Carbon, Alloy, and Stainless Steel |

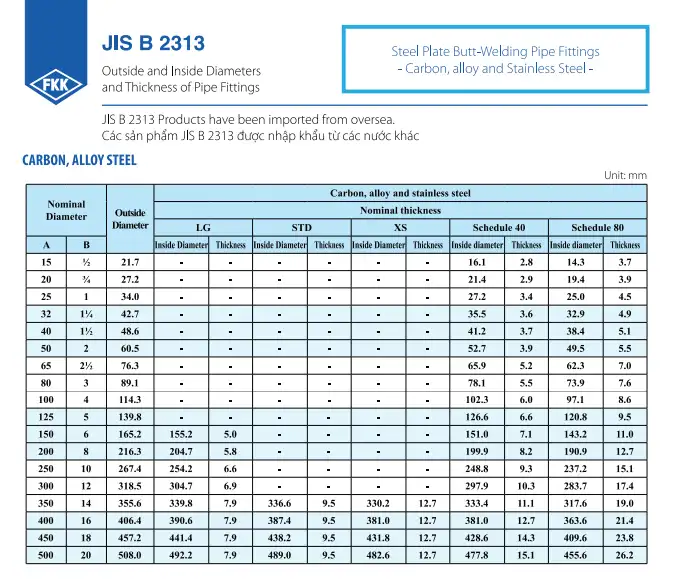

| JIS B2313 | Steel Plate Butt-Welding Pipe Fittings Carbon, Alloy, and Stainless Steel |

1. Standard B2311

2. Standard B2312

3. Standard B2313

If you require FKK welding fittings and need a catalog to present to the investor or for research, you can download it here: FKK welding fittings catalog

Production process of FKK welding fittings

Elbow production line

One of the most common methods for producing welded elbows is the steel pipe hot-forming method.

Specifically, this method will include the following steps:

- Input raw materials are steel pipes with corresponding specifications available on the market.

- Then these steel pipes into the hot bending machine to heat the raw materials.

- During this heating process, the steel pipe expands, becoming more ductile. At this time, steel pipes are continuously extruded into the machine until steel is formed according to the batch specifications.

- Then the piece of steel pipe that has just been bent is cut from the long pipe. Continue the post-processing steps to make the surface smoother and more beautiful.

Welded tee production line

The characteristic of the steel pipe used to produce a tee is that its outer diameter is larger than the finished tee. The reason is that when pressing and shaping it in the mold, the structure of the steel pipe will change and become smaller.

During the process of forming the tee in the mold, the manufacturer can customize the thickness of the product according to the desired specifications.

For the specific production process, please see the two photos below.

Welding cap production line

Of all the types of FKK welding fittings, welding caps are perhaps the easiest to manufacture.

Although it takes many steps to have a complete welding cap product, it can be summarized in two main stages:

- Cut steel plates of the desired thickness into circular pieces.

- Using a rolling mill, roll this steel sheet in a conical mold while the billet is heated to facilitate shaping.

For specific procedures, please see the photo below.

See more: FKK galvanized welding cap

Bao Tin Steel: Address providing genuine FKK welding fittings

Currently, on the market, there are a few establishments that distribute products of the FKK brand. However, Bao Tin Steel Company Limited is still a trusted name and the official distributor of FKK welding fittings.

With more than 10 years on the market, Bao Tin Steel has affirmed its position in the industrial supplies industry in general and the steel industry in particular. The company has a team of experienced and highly specialized experts and employees who always work professionally. The company always ensures correct, sufficient, and quality delivery.

So, together, we have explored the FKK Fittings catalog. Bao Tin Steel hopes that the above information will help you better understand the product as well as choose to buy quality products under the FKK brand.

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ