Flange hole division formula

Flanges are very familiar accessories to many mechanical brothers. They help connect parts to create a complete pipeline system. However, not all brothers in the profession know and understand the formula for dividing holes on the flange. This makes it difficult for many brothers to manufacture and process flanges.

Flange size

As in previous articles, Bao Tin Steel has repeatedly affirmed that flanges are extremely diverse. Not only in material and structure but also in size. To accurately divide the hole on the flange, the size parameters of the flange are extremely important.

Important dimensions of flanges

There are 2 parts that most technicians pay attention to: the size and number of holes on the flange. Specifically, a flange will have 6 important dimensions including:

- Bolt size.

- Bolt hole size.

- Flange inside diameter: This is the connection to the outside diameter of this accessory.

- Flange outside diameter: Measured from the outside edge to the opposite face.

- Number of bolts.

- Flange thickness.

Flange standards

Normally, the larger the flange diameter, the more holes there are and the narrower the distance between the holes. For example, flanges with small diameters from DN15, DN20, DN5, and DN32 are often arranged with 4 holes. Medium diameters range from DN40 to DN100; larger surfaces often have 8 holes. Along with that, flanges are manufactured based on specific standards and technical parameters. These flange standards will determine the basic factors. Including thickness, outer diameter, inner diameter, hole center, hole distance, error, hole size,… of the flange. Currently, there are 4 standards on the market, including:

- ANSI (American National Standards Institute) – American standards.

- BS (British Standards Institute) – British standards.

- DIN (Deutsches Institut für Normung) – German standards.

- JIS (Japan Industrial Standard) – Japanese standards.

Therefore, to complete the flange machining process well, in addition to determining the exact number of holes you want to create, you need to learn and master the standards for manufacturing flanges properly.

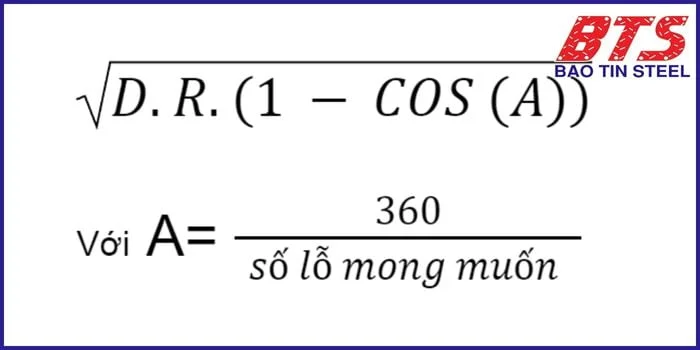

Flange hole division formula

Once you have the dimensions of the flange (including diameter and radius), you can proceed to calculate the hole division on the flange. Below is the standard formula that many people apply in their daily work:

In there:

- D: is the flange diameter

- R: is the flange radius

- A: is the angle measurement between the 2 holes on the flange

For example: We have a flange with a diameter of D= 150mm => R= 75mm. We want to create 5 holes on this flange, then apply the formula for dividing holes on the flange. We get:

Với A= 360/5 = 72 (độ)

=> Applying the formula, we will calculate the distance between the 2 holes as 88 (mm)

This is one of the simple and extremely easy-to-understand formulas that many people apply. Just look at it and you can apply it right away, right?

Flange hole splitting process

The most important and also the most troublesome step is the calculation, which is solved. Next, you will proceed to divide the holes on the flange. At this point, the work is much easier, you just need to follow these steps:

- Step 1: Clean the flange and place the flange on a flat, balanced surface with enough light. Step 2: After

- Calculate the distance between the 2 holes by dividing the hole on the flange by x, and open the compass. Use a mm ruler to open the distance between the 2 legs of the compass according to the number x found.

- Step 3: Choose a point on the circle of the flange as the center and hold one leg of the compass there. Mark the point where the other leg of the compass touches. The distance between the two compass marks is the distance between the two holes of the flange. Keep marking like that until the leg of the compass returns to the original center point.

Note when performing hole division on the flange

To ensure the creation of standard flanges, when dividing holes on the flange, you need to note:

- Determine what type of flange to use in what application. What flange material? What standard? What is the desired size?…

- Prepare all tools such as calculator, compass, ruler

- Have a firm grasp of the formula to calculate accurately

- Do it in a flat, clean, well-lit place.

The above is the knowledge that Bao Tin Steel believes is extremely useful for those who are working in mechanics. Specifically, the work of machining flanges. The above formula for dividing holes on the flange will help you do the job faster and more conveniently. Contact us now if you need support!

Tiger Steel is a branch of Bao Tin Steel.

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ