Are you researching handwheel butterfly valves but are unsure if this type of valve is truly right for your system? Thép Bảo Tín understands that with the countless industrial equipment options available today, choosing the correct valve—especially for water, air, fire protection (PCCC), or chemical systems—is not an easy task.

The handwheel butterfly valve is one of the most widely used valve types due to its flexible open/close operation, simple design, and reasonable investment cost. But beyond being “cheap and easy to use,” this valve also has many technical features that, if you understand them correctly, can lead to significant savings on operating costs and a remarkable increase in system durability.

In this article, Thép Bảo Tín will explore everything with you: what a handwheel butterfly valve is, how it works, its strengths and weaknesses, and how to choose the right valve for your specific application. Let’s get started!

What is a handwheel butterfly valve? Should I use it?

A handwheel butterfly valve is a type of industrial valve used to open, close, or regulate flow in a piping system.Unlike a standard lever-operated butterfly valve, the handwheel valve is equipped with a control handwheel and a gearbox. This makes operation more effortless, especially for larger valves of DN100 and above.

When you turn the handwheel, the force is transmitted to the stem via the gearbox, which causes the valve disc to rotate 90 degrees, thereby adjusting the flow inside the pipeline. This design not only enables precise opening and closing but also ensures the valve remains in position due to a self-locking mechanism, which is crucial for high-pressure systems.

Should I use it?

Bao Tin Steel asserts that the handwheel butterfly valve is a smart choice for most common industrial applications, such as clean water, fire protection (PCCC), HVAC, compressed air, and light chemicals.

Advantages

- Easy to operate, even for large sizes, thanks to the gearbox.

- Fast open/close, making it suitable for systems that require a flexible response.

- More affordable than a ball or globe valve of the same size.

- Simple design, easy to maintain, and gaskets can be replaced as needed.

Disadvantages to Note

- The valve still causes flow obstruction even when fully open (because the disc remains in the pipe).

- Not suitable for fluids containing large debris, as the valve disc can easily get stuck.

- If throttled too frequently, the gasket may wear out faster than normal.

If you need a valve that is reliable, user-friendly, affordable, and still technically sound, the handwheel butterfly valve is a worthy option to consider.

Basic Technical Specifications

When selecting a handwheel butterfly valve, you need to pay special attention to the basic technical specifications below. These are not just “numbers on paper”; they directly impact the performance, lifespan, and safety of the system you are operating.

- Nominal Size (DN): DN50 – DN600, can go up to DN1200 depending on the manufacturer.

- Body Material: Stainless steel, ductile iron, steel, plastic, etc.

- Valve Stem: Made from materials such as ductile iron, stainless steel, etc.

- Connection Type: Wafer, Lug, Flanged.

- Sealing Gasket: EPDM, NBR, PTFE, Viton.

- Valve Disc: Stainless steel, plastic, ductile iron with a PTFE coating, etc.

- Connection Standards and Working Pressure: BS4504 – DIN 2632 (PN10, PN16, PN25), JIS B2220 (10K, 16K), ASME B16.42 (150LB).

- Working Medium: Water, air, oil, steam, chemicals, etc.

- Operating Mechanism: Handwheel + Gearbox.

- Working Temperature: -10°C to 200°C (depending on the body and gasket materials). Common Origins: South Korea, China, Malaysia.

You can refer to some of the products officially distributed by Bao Tin Steel.

Structure and Working Principle of a Handwheel Butterfly Valve

Despite its relatively simple appearance, the handwheel butterfly valve is an optimized mechanical device designed for efficient operation, high strength, and excellent sealing integrity.

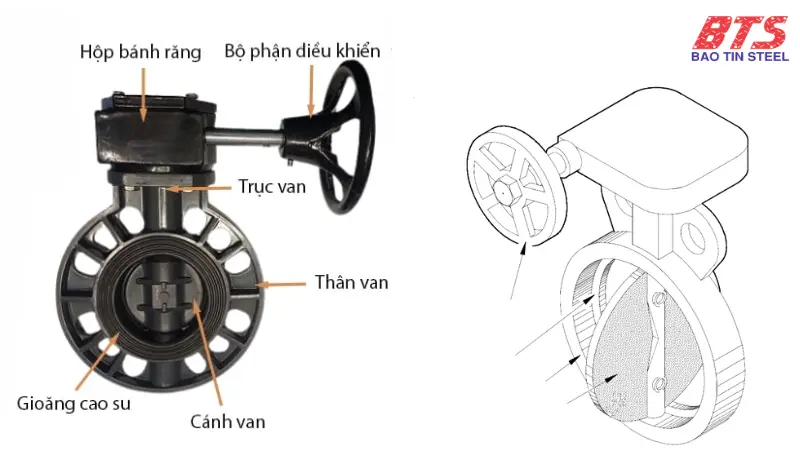

Structure of handwheel butterfly valve

- Body The body is hollow and round, connecting directly to the piping system via Wafer, Lug, or Flanged connections. Common materials include grey cast iron, ductile iron, stainless steel, steel, or plastic.

- 2. Disc This is the “butterfly wing” located in the middle of the flow. By rotating this disc, you can adjust the flow rate. The material is typically stainless steel, cast iron, or plastic, depending on the fluid medium.

- Stem It connects the handwheel to the valve disc, transmitting torque from the operator to the disc. It is usually made from stainless steel (304/316) to ensure strength and corrosion resistance.

- The handwheel is where you directly operate the valve. The handwheel is wheel-shaped and turns effortlessly thanks to the gearbox system.

- Box This is the biggest difference between a handwheel and a lever-operated butterfly valve. The gearbox makes it easier to turn, increases torque, and maintains the desired opening angle (self-locking). This is extremely important for valves of DN150 and above; without it, the valve would be very heavy and difficult to operate by hand.

- 6. Gasket Located between the body and the disc, the gasket is the key factor in creating a tight seal and preventing leaks.

- EPDM, NBR: used for water, compressed air

- PTFE, Viton: used for chemicals, high temperature

Operating principle and operating features

The handwheel butterfly valve operates on a simple yet effective gear drive principle. Its strengths are that it’s easy to turn, can be throttled, and holds a stable open position—and this is what makes it a reliable choice in the thousands of industrial piping systems that our customers operate every day.

With a handwheel butterfly valve, every control movement begins with… a simple turn.

Handwheel Open/Close Mechanism

When you turn the handwheel (also known as the “vô lăng”), the force is transmitted through the gearbox and then to the valve stem, causing the valve disc to rotate around its central axis.

- To open the valve: The disc gradually moves from a position perpendicular to the flow to a position parallel to the flow. When it is parallel, the valve is fully open (at a 90° angle).

- To close the valve: The disc rotates back, pressing tightly against the gasket to completely stop the flow.

Because the disc is always in the flow path, you can hold it at any open angle to throttle the flow. This is a key advantage that makes the handwheel butterfly valve far more flexible than on/off valves like ball or gate valves.

Self-locking Mechanism – Maintains a Stable Open Angle

A major advantage that Bao Tin Steel often advises its clients on is the handwheel butterfly valve’s ability to automatically maintain its open angle, thanks to a self-locking gearbox. Even if the pressure in the pipeline changes, the valve disc will not rotate on its own. This is a critical feature for systems that require stable flow control.

Classification of common handwheel butterfly valves

Not all handwheel butterfly valves are the same. The right choice depends on the fluid medium, system pressure, installation conditions, and budget. Here are the three main classification criteria:

Classification by manufacturing materials

The material directly affects the valve’s resistance to heat, pressure, and corrosion. You should choose based on the type of medium in your system:

| Valve Type | Material | Common Applications |

|---|---|---|

| Cast Iron Handwheel Butterfly Valve | Cast iron body, cast iron/stainless steel disc | Clean water systems, fire protection (PCCC), compressed air |

| Stainless Steel Handwheel Butterfly Valve | Stainless steel 304/316 | Pharmaceuticals, food, corrosive chemicals |

| Steel Handwheel Butterfly Valve | Heat-resistant cast steel | Hot oil, hot steam, high pressure |

| Plastic Handwheel Butterfly Valve | PVC, UPVC, PP | Chemicals, mild acids, water treatment industry |

Classification by connection type

The connection type determines the installation and maintenance of the valve. Each type has its advantages and disadvantages:

| Connection Type | Characteristics | Pros/Cons |

|---|---|---|

| Wafer | The valve is clamped between two flanges | Pros: Compact, inexpensive, easy to install. Cons: The Entire assembly must be removed for maintenance |

| Lug | Has threaded bolt holes; bolts are tightened from one side | Pros: Allows one end of the pipe to be removed without affecting the entire system. Cons: Suitable for localised maintenance only |

| Flanged | Has two integrated flanges | Pros: Secure, good sealing. Cons: Suitable for large DN and high-pressure systems, more complex installation |

Note: You should check the flange standard (JIS, DIN, ANSI) of the pipeline to select a compatible valve.

Classification by brand & origin

Handwheel butterfly valves are now widely available from many countries. Some brands that Bao Tin Steel often supplies and customers highly appreciate:

| Origin | Notable Brands |

|---|---|

| South Korea | Wonil, Joeun, YDK |

| China | Shinyi, JS, BTL |

| Malaysia | AUT, ARV |

| Vietnam | Minh Hòa, ROBO |

Practical Applications of Handwheel Butterfly Valves

One of the reasons the handwheel butterfly valve is so widely favoured is its “versatility”—it’s suitable for a variety of media, industries, and project types. Whether you work in civil construction, water treatment, the food industry, or complex technical systems, you have likely encountered or used this type of valve without even realising it.

Let’s join Bao Tin Steel in reviewing some of the most common applications today:

- Water supply and wastewater treatment systems

- Used in systems for conveying oil, gas, and industrial solvents

- Food, beverage, and pharmaceutical production

- HVAC systems (Heating, Ventilation, and Air Conditioning)

- Compressed air systems, marine vessels, and heavy industrial plants

Handwheel butterfly valves are a common sight in the clean water piping systems we use daily, so they are not too unfamiliar. However, this type of valve is not suitable for all systems. You should consult with experts to select the right product, which will help your system operate as efficiently and safely as possible.

Should I choose a handwheel or lever butterfly valve?

Comparison table: Lever butterfly valve vs. Handwheel butterfly valve

| Criteria | Lever-Operated Butterfly Valve | Handwheel-Operated Butterfly Valve |

|---|---|---|

| Operation Mechanism | Directly turn the lever 90° to open/close | Turn handwheel → gearbox transmits motion → disc rotates |

| Suitable Size Range | DN15 – DN150 (up to DN200–DN300 depending on the manufacturer) | DN50 – DN600 (most effective from DN125 and up) |

| Operating Force | Requires significant hand force for valves DN100+ | Lighter thanks to the gearbox |

| Throttling Capability | Can throttle, but unstable at intermediate open angles (15–75°, prone to gasket wear and vibration. | More stable throttling; gearbox maintains precise open position |

| Self-Locking Capability | Limited – depends on the lever’s toothed disc | Good – thanks to the self-locking gearbox mechanism |

| High Pressure/Torque Resistance | Poor – not suitable for high pressure | Good – supports operation for large sizes or high pressure |

| Operating Speed | Fast – one single turn opens/closes the valve | Slower because it requires multiple turns |

| Cost | Cheaper (~10–20%) | More expensive due to the added gearbox |

| Common Applications | Clean water, fire protection, small compressed air, light chemicals, small pipe sizes | Large-scale industry, large-DN fire protection, wastewater, oil and gas, HVAC systems, corrosive chemicals, high-pressure environments |

| Maintenance/Repair | Easy – fewer components | Requires periodic gearbox inspection |

| Lifespan & Throttling Stability | Lower if adjusted frequently | Higher thanks to light, even, and precise force adjustment |

General assessment

From the comparison table above, you can clearly see that both lever-operated and handwheel-operated butterfly valves are based on the same principle, but their operating methods and application ranges differ significantly.

If you need a valve for a simple system with small pipes and low pressure, such as:

- Domestic water systems

- Small fire protection (PCCC) cabinets

- Branch lines in compressed air systems

→The lever-operated butterfly valve is a reasonable and economical choice. It’s simple to operate with just a single turn, easy to install, easy to repair, and the price is affordable. However, remember not to maintain an open angle between 15°–75° for too long, as this can easily wear out the gasket and cause premature leaks.

Conversely, if you operate in a heavier industrial environment, such as:

- HVAC systems in buildings and factories

- Wastewater and chemical treatment pipelines

- Fire protection (PCCC) with large pipelines (DN150 and up)

- High-pressure media that require a stable seal

→ The handwheel butterfly valve is the more worthwhile choice. Thanks to the gearbox, operation is much lighter, allowing you to flexibly adjust the open angle. More importantly, it can maintain a precise open position—something a lever valve cannot do well in high-pressure systems.

Latest price list of handwheel butterfly valves

If you’re considering investing in handwheel butterfly valves for your system, price is always a key factor to consider carefully. At Bao Tin Steel, we understand that in addition to quality and durability, a reasonable and transparent price is what every customer is concerned with.

Below is a REFERENCE price list for common types of handwheel butterfly valves, updated for the market in June 2025:

| Size (DN) | Cast Iron Valve with Stainless Steel Disc (Common) | 304 Stainless Steel Full Body Valve | PVC Handwheel Valve |

|---|---|---|---|

| DN50 (2″) | 530,000 – 620,000 VND | ~1,450,000 VND | ~490,000 VND |

| DN100 (4″) | 850,000 – 980,000 VND | ~2,100,000 VND | ~790,000 VND |

| DN150 (6″) | 1,350,000 – 1,600,000 VND | ~3,200,000 VND | ~1,200,000 VND |

| DN200 (8″) | 1,900,000 – 2,300,000 VND | ~4,600,000 VND | ~1,600,000 VND |

| DN250 (10″) | 2,900,000 – 3,400,000 VND | ~6,200,000 VND | Contact for price |

| DN300 (12″) | 3,600,000 – 4,300,000 VND | ~8,000,000 VND | Contact for price |

Note: Actual price may vary by brand, origin (Korea, China, Malaysia), connection standard (wafer/flange/lug) and order quantity.

=> See more: Latest Butterfly Valve Price List 2025

Tips for Selecting the Right Handwheel Butterfly Valve

Bao Tin Steel has partnered with many engineers, contractors, and investors in selecting valves. Here are the insights we’ve gained from hundreds of projects.

Understand the Fluid Medium in the Pipeline

Before you consider price or brand, you must identify what liquid or gas you are conveying:

| Fluid Medium | Recommended Valve Choice |

|---|---|

| Clean water, compressed air | Cast iron body, stainless steel disc, EPDM gasket |

| Wastewater, mild chemicals | Cast iron body, PTFE/NBR gasket |

| Strongly corrosive chemicals | Full-body stainless steel 316 or plastic valve (PVC, UPVC) |

| Oil, hot steam, high-temperature environments | Heat-resistant steel valve, Viton or Graphite gasket |

Choose the Right Size and Connection Type

- Don’t just look at the outer pipe diameter (phi) – use the correct DN standard instead (e.g., DN100 = 4″).

- For flanged systems, check if the connection standard is JIS, ANSI, or DIN.

- The Wafer valve type is compact and cost-effective, but the entire assembly must be removed if a replacement is needed.

- Lug or Flanged types are easier to maintain – suitable for large DN systems.

Don’t Skimp on the Gearbox

For valves DN125 and above, a handwheel almost always requires a gearbox:

- Makes turning easy, requiring less effort.

- Maintains a fixed open angle (self-locking), preventing vibration or automatic closing when pressure increases.

- Increases the lifespan of the valve stem and sealing gasket.

Choose a Reputable Brand with Clear Certification

- Prioritise brands with complete CO-CQ documentation, easy warranty, and technical support.

- Avoid “super cheap, unbranded” products, as they carry a very high risk of leakage, broken handwheels, or jammed discs.

Tip: Wonil, Joeun (South Korea); AUT, ARV (Malaysia); Shinyi, JS (China); and Minh Hòa (Vietnam) are brands that have been field-tested over many years.

Spare Parts & Easy Maintenance

- Prioritise valves where the gasket, handwheel, and gearbox can be replaced individually, making repairs easier when needed.

- If the system is critical, you should keep one spare valve of the same type in stock for quick replacement in case of an incident.

Every system has different requirements, but if you understand the fluid medium, pressure, and temperature, and choose the correct material, size, and connection, the handwheel butterfly valve will be a reliable partner for 5–10 years or more. Don’t choose based on the lowest price—choose based on long-term operating efficiency.

Installation and Maintenance Guide for Handwheel Butterfly Valves

Correct Installation Guide

Pre-installation Preparation:

- Ensure the system is depressurised and has been drained.

- Clean the flanges and pipelines: remove scale, rust, and grease.

- Check the valve’s open angle before installation: the valve should be in a partially open state (~15°–20°) to avoid damaging the disc.

Installation Steps:

- Place the valve in the correct flow direction (if there is a “FLOW” symbol on the body).

- Align the centre of the valve with the two pipeline flanges.

- Install the bolts symmetrically, tightening them gradually in a 5–6 point star pattern.

- Do not overtighten one side—this can easily warp the body or jam the disc.

- After tightening, test-turn the handwheel to ensure the disc opens/closes without rubbing.

Common Installation Errors:

- Overtightening unevenly → the disc collides with the flange.

- Installing a fully closed valve → prone to damaging the gasket.

- Using the wrong type of adhesive/lubricant → corrosion of the disc/gasket.

Maintenance Guide for Handwheel Butterfly Valves

- Periodic Check Frequency: Every 3–6 months, depending on the operating environment and usage intensity.

Items to Check:

| Component | Action Required |

|---|---|

| Handwheel & Gearbox | Perform a test operation; lubricate the gearbox if it’s dry. |

| Valve Stem | Check for play/looseness; retighten if necessary. |

| Sealing Gasket | Check for leaks; if it appears damp, the gasket may be worn. |

| Valve Disc | Open the valve to inspect the surface for deposits, corrosion, or cracks. |

| Connection Bolts | Retighten if loose; apply even force to avoid over-tightening, which could crack the valve body. |

Safety Note: Before disassembling, installing, or performing a detailed inspection, always:

- Disconnect the system and relieve the pressure.

- Wear protective gear if the medium is a chemical or hot water.

Choose the Right Valve – Install It Correctly – Enjoy Long-term Efficiency

The handwheel butterfly valve is more than just a device for controlling flow; it’s a critical link in the entire technical system, from water supply, wastewater treatment, and fire protection (PCCC) to chemical processing, HVAC, and food production.

When you understand the fluid medium, pressure, and temperature, and choose the right material, connection, and brand, the valve will not only operate smoothly but will also help you save time, reduce maintenance costs, and prevent many unexpected incidents.

Contact Bao Tin Steel – Get the Right Advice from the Start

Still unsure about choosing the right valve? Let Thép Bảo Tín partner with you!

- Quick quotes within 30 minutes

- Full CO-CQ documentation and technical drawings

- Genuine products with large quantities in stock

- Technical support before, during, and after the sale

Contact Bao Tin Steel now to get advice and the best quote for handwheel butterfly valves:

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ