Hydraulic Check Valve: Structure, Working Principle, and Applications

Have you ever wondered how hydraulic systems — like presses, cranes, or lifts — operate safely and accurately, even when holding heavy loads or preventing unwanted movement?

The secret lies in one essential component: the hydraulic check valve.

A hydraulic check valve (also known as a non-return valve) allows fluid to flow in only one direction while completely blocking reverse flow. This not only protects key components such as pumps and cylinders from pressure shocks but also ensures consistent and safe operation.

In this article, Bao Tin Steel explains what a hydraulic check valve is, how it works, its types, applications, and some useful selection and installation tips.

What Is a Hydraulic Check Valve?

A hydraulic check valve is a mechanical device that automatically permits flow in one direction and prevents backflow.

When inlet pressure exceeds a preset cracking pressure, the valve opens to let oil pass through; when the pressure drops or reverses, it closes instantly — protecting the system from damage.

Hydraulic Check Valve

Hydraulic Check Valve

This automatic mechanism helps maintain pressure, stabilise flow direction, and protect equipment from reverse surges — making check valves one of the most widely used components in hydraulic systems.

Structure and Working Principle

Although check valves vary in design, they share a few core components:

-

Valve Body: Made of steel, cast iron, or aluminium alloy — connects to the hydraulic line (threaded, flanged, or cartridge type).

-

Closing Element:

-

Ball: A metal or polymer sphere.

-

Disc or poppet: A conical or flat sealing element.

-

-

Valve Seat: Surface where the ball/disc seals when closed.

-

Spring: Keeps the valve closed until the inlet pressure exceeds the cracking pressure.

-

Seals (O-rings): Prevent oil leakage.

Structure of a hydraulic one-way valve

Structure of a hydraulic one-way valve

Operation:

- When fluid pressure on the inlet side overcomes spring tension, the valve opens.

- When pressure drops or reverses, the spring pushes the sealing element back to close the flow path.

This ensures one-way flow without external control.

Main Types of Hydraulic Check Valves

Types of Check Valves for Hydraulic Systems

Types of Check Valves for Hydraulic Systems

1. Standard Hydraulic Check Valves

Work automatically based on the pressure difference.

Ball-Type Check Valve

- Pros: Simple, durable, less affected by debris.

- Cons: Slight noise at high flow, less tight at extreme pressures.

- Uses: Low to medium pressure systems.

Poppet/Disc-Type Check Valve

- Pros: Excellent sealing, smooth and quiet operation.

- Cons: More sensitive to contamination.

- Uses: Industrial and construction machinery.

2. Pilot-Operated Check Valves (Counterbalance Valves)

An advanced version featuring a pilot port that allows controlled reverse flow when a control signal (pilot pressure) is applied.

- Pros: Locks hydraulic cylinders, prevents load dropping (“creep”), and allows controlled motion.

- Applications: Lifting systems, hydraulic presses, construction machinery.

Advantages and Limitations

Advantages:

- Allows one-way flow, prevents reverse pressure.

- Protects pumps, cylinders, and actuators.

- Maintains system pressure and load position.

- Simple, durable, automatic, and cost-effective.

Limitations:

- Cannot control flow or pressure.

- Slight pressure drop due to cracking pressure.

- Sensitive to dirty oil if the filtration is poor.

Typical Applications

Hydraulic check valves are widely used in:

- Hydraulic presses and forming machines.

- Lifting systems (cranes, forklifts, hydraulic elevators).

- Central hydraulic power units.

- Industrial automation and machinery.

- Construction equipment (excavators, loaders, bulldozers).

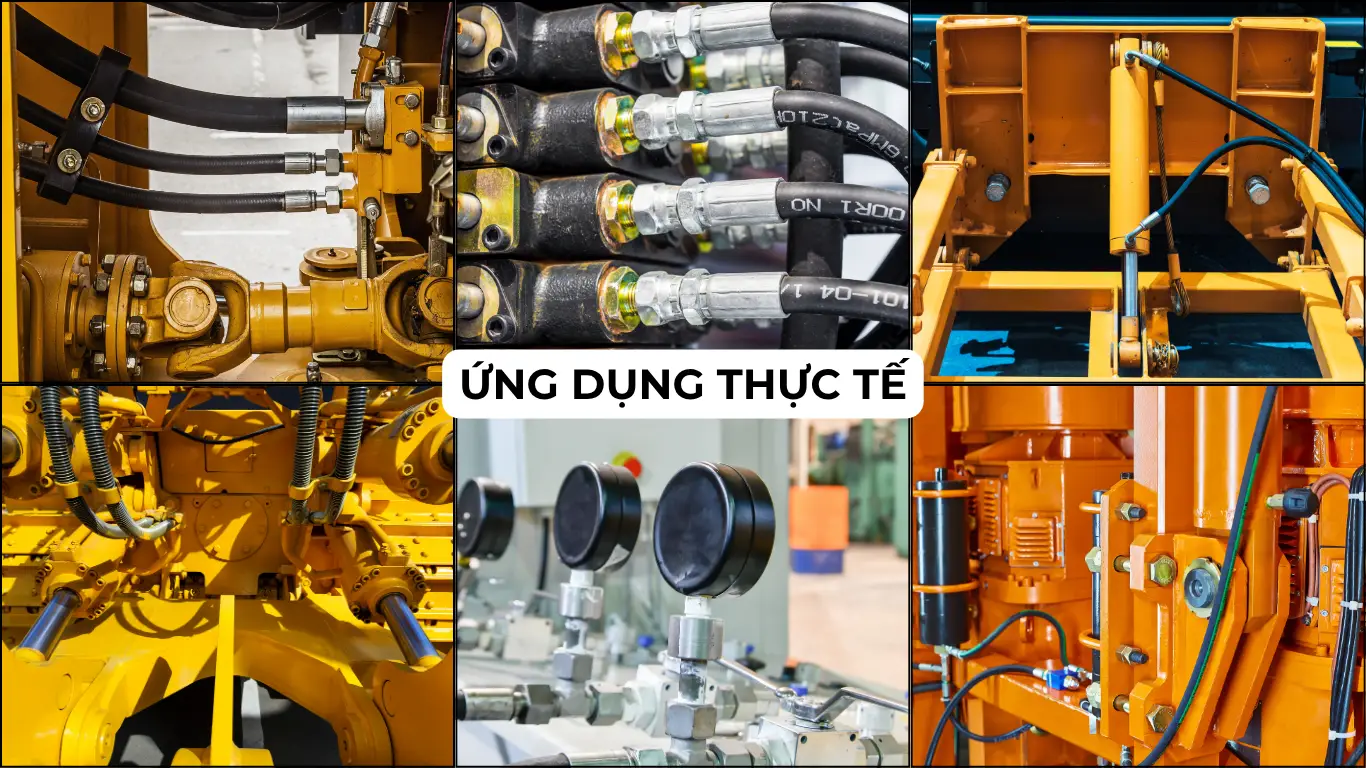

Practical applications

Practical applications

Reference Price Range (2025)

| Type | Size | Pressure | Material | Price (VND) |

|---|---|---|---|---|

| Standard spring type | 1/4”–1” | 250 bar | Zinc-plated steel | 180,000–520,000 |

| Threaded (M/F) | 1/2”–2” | 300 bar | Stainless steel 304 | 420,000–1,250,000 |

| Pilot-operated | 3/8”–1” | 315 bar | Carbon steel | 1,300,000–2,800,000 |

| Cartridge type | D08–D16 | 320 bar | Alloy steel | 1,100,000–2,000,000 |

| Imported (Yuken/Nachi) | 1/4”–1” | 210–350 bar | Hardened steel | 1,600,000–3,500,000 |

Note: Prices may vary depending on brand, country of origin, and pressure rating.

Installation and Maintenance Tips

To ensure long-term performance, follow these key steps:

- Check flow direction: Install according to the arrow on the valve body.

- Clean all fittings and threads before installation.

- Use proper sealing materials: PTFE tape or hydraulic sealant.

- Tighten with correct torque.

- Test for leaks at low pressure first.

- Keep hydraulic oil clean.

- Avoid overpressure and overheating.

- Inspect regularly for leaks, vibration, or noise.

Installation Guide for Check Valve in Hydraulic System

Installation Guide for Check Valve in Hydraulic System

Choosing the Right Check Valve

When selecting, consider:

- Working pressure and flow rate.

- Fluid type and temperature.

- Cracking pressure.

- Mounting type (threaded, flanged, cartridge).

- Reliable brand and supplier support.

Pro Tip: Always choose a valve rated 20–30% higher than your system’s working pressure for better safety and durability.

Conclusion

Small but powerful, hydraulic check valves play a crucial role in ensuring pressure stability, safety, and efficiency.

From basic spring-loaded valves to advanced pilot-operated designs, they keep systems running smoothly and reliably.

For consultation or product selection, contact Bao Tin Steel — your trusted partner in hydraulic technology.

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ