In the construction industry, choosing the right materials plays a key role in determining the sustainability, safety, and economic efficiency of a project. Iron and steel—two seemingly similar materials—actually have distinct differences in chemical composition, mechanical properties, and practical applications. So how to distinguish between iron and steel to choose the right material for your needs?

This article will analyze the basic concepts, compare them in detail, and give practical advice to help you easily make the right material decision.

Are iron and steel the same?

The short answer is no. Iron (Fe) is the fourth most abundant element in the Earth’s crust and is the primary constituent of the Earth’s core. Steel is an alloy of iron and other elements.

How to distinguish iron and steel in detail

Now that we understand the basic concept, let’s dive into the specific differences between iron and steel across important aspects like composition, properties, manufacturing process, and practical applications.

| Characteristic | Iron | Steel |

| Carbon content | Very little or no carbon (typically < 0.035%) | From 0.02% to 2.14% carbon |

| Hardness | Soft, pliable | Much harder than iron (can be 1000 times harder) |

| Tensile strength | Short | Higher than iron |

| Brittleness | Not brittle | High carbon content can make steel more brittle. |

| Manufacture | – Produced in blast furnaces, reducing iron ore with coke to pig iron – Difficult to find in free form, impurities must be removed by chemical reduction |

– Refining pig iron with oxygen to reduce carbon content – Other elements may be added to produce steels with special properties |

| Colour | Shiny silver colour | Usually silver or grey |

| Application | Iron is used in a variety of applications, including the production of cast iron, steel, and other alloys. | Steel is one of the most popular materials in the world, used in construction, furniture, mechanical industry, and many other fields. |

| Price and durability | Cheaper but not durable, susceptible to corrosion when exposed to humid environments. | More expensive but has a long life and is less affected by weather and the environment. |

Should I choose iron or steel?

The choice between iron and steel depends on the specific requirements of each construction and project.

When to use iron?

- Decorative products or utensils that do not require high durability.

- Small-scale projects that are not frequently exposed to harsh environments.

When to use steel?

-

Large structures such as bridges, high-rise buildings, or items requiring high load-bearing capacity.

-

Applications in harsh environments, requiring rust resistance and long life.

Choosing the right material will not only ensure efficiency but also optimize your project budget.

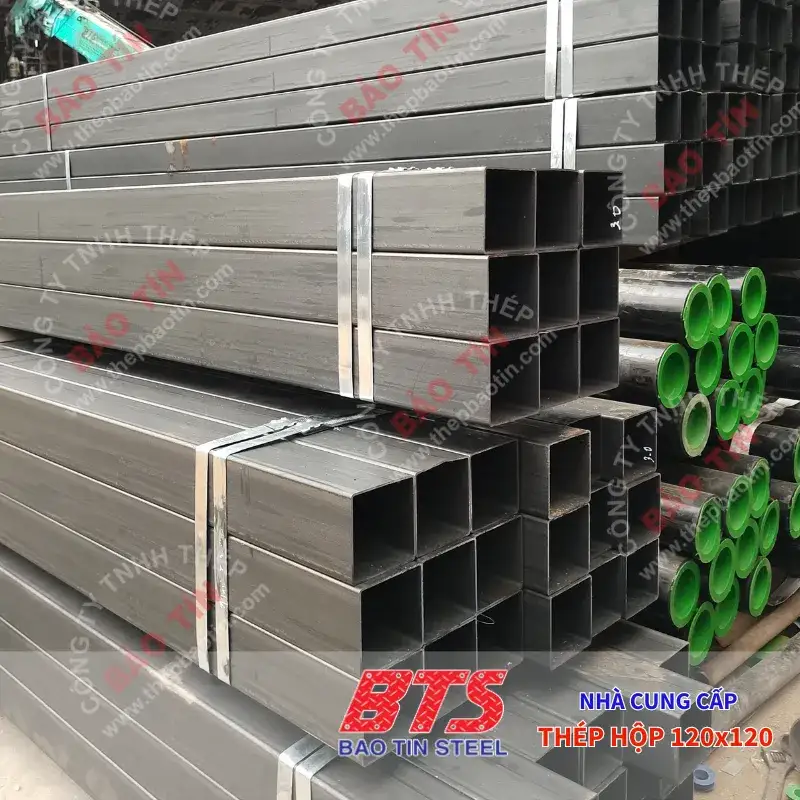

Please refer to some steel products at Bao Tin Steel:

Advice from the experts

To make the right choice, you should:

- Assessing project needs: If the project requires high durability and load-bearing capacity, steel is the top choice.

- Consider the usage environment: In humid or corrosive environments, stainless steel should be preferred.

- Budgeting: For small projects or limited budgets, iron can be an economical choice.

Conclude

Tiger Steel is a subsidiary of Bao Tin Steel

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ