PE-coated steel pipes are gaining popularity due to their numerous advantages. Currently, these pipes are trending as replacements for materials such as plastic, wood, and metal bars. What are the advantages and technical specifications of these pipes? Let’s find out more about the PE plastic-coated steel pipe model with Bao Tin Steel!

What is a PE-coated steel pipe?

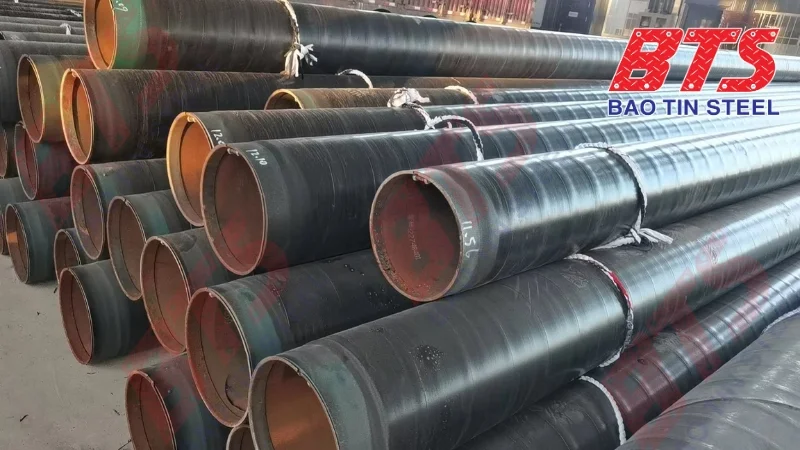

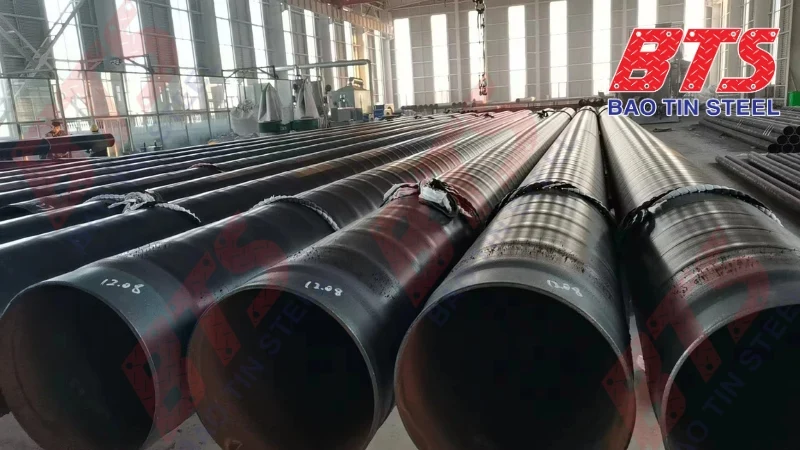

Steel pipes are essential construction materials for various projects. To enhance their durability and longevity, manufacturers have introduced polyethylene-coated steel pipes that comply with the highest anti-corrosion standards.

PE-coated steel pipe, or polyethylene-coated steel pipe, is a type of steel pipe that has one to three layers of PE plastic applied to its exterior. This coating enhances the pipe’s corrosion resistance and helps slow down the oxidation process on its surface.

Currently, the polyethylene-coated steel pipe product has a thickness ranging from 0.7 to 1.2 cm. To meet diverse requirements, coated pipes from +2PE and +3PE are now available.

Technical specifications of polyethylene-coated steel pipe

Polyethylene-coated steel pipes at Bao Tin Steel are imported from China, Korea, Japan, etc., meeting the standards of ASTM A53, API 5L, ASTM A106, etc. with the following technical parameters:

- Pipe type: PE-coated steel pipe, 2PE-coated steel pipe, 3PE-coated steel pipe.

- Application: Used for natural gas, oil, water, waste systems, etc.

- Size: DN100 – DN30000

- 2PE pipe coating standards: DIN 30670 – 1991, SY/T 0413-2002, GB/T 23257-1009, ISO 21809-1-2009,…

- 3PE pipe coating standards: DIN 30670-1991, CAN/CSA Z245.21-2010, ISO 21809-1-2009, SY/T 0413-2002, GB/T 23257

- Various steel pipe sizes

- Pipe lengths 6m, 9m, 12m and especially receive cutting according to customer requirements

The thickness of the polyethene (PE) plastic coating on the steel pipe.

You may not know, that the PE plastic layer covering the steel pipe has different thicknesses depending on the outer diameter and nominal size (DN). Specifically:

- If DN<100 then PE plastic thickness will be 2.5mm

- 100<DN<250 then PE plastic thickness is 2.7mm

- 250<DN<500 then PE plastic thickness is 2.9mm

- 500>DN<800 then PE plastic thickness is 3.2mm

- DN<800 then PE plastic thickness will be 3.7mm

After the steel pipe is coated with polyethene, it will be placed in a heating system set to a temperature of 180 to 280 degrees Celsius. Next, the pipe will be electrostatically sprayed with epoxy powder. Following this, it will undergo another electrostatic spray with polyethene. Afterwards, the polyethylene pipe will be extruded and then cooled by applying water. The final stage involves processing and finishing with an anti-corrosive lacquer.

PE-coated steel pipe accessories included

Plastic-coated steel pipe fittings include many different types, each with its function, helping to connect steel pipes firmly and flexibly. Some common types of fittings include:

- HJ coupling for plastic-coated steel pipe: This is the most common type of coupling, used to connect straight pipe sections.

- T-joint: Used to create branches or divide the flow.

- Corner joint: Helps change the direction of the pipe.

- Plastic pipe plug: Used to seal the end of the pipe. It is often used for pipes with diameters of 27-28mm.

- Bolts and nuts: Used to secure joints. They are screwed together through threads.

Plastic-coated steel pipe fittings come in a variety of specifications, sizes and designs. This allows users to create many creative designs for applications in life. At the same time, these plastic pipe fittings also help make installation quicker and more aesthetically pleasing. Saving a lot of time and effort.

Advantages and applications of PE-coated steel pipes

Advantages of PE-coated steel pipes

| No. | Advantage | PE-coated steel pipe | Metal bar | Plastic | Wood |

| 1 | Withstand high temperatures up to 1000 degrees C | x | |||

| 2 | Diverse and aesthetic colours | x | x | x | |

| 3 | Unaffected by oily surroundings | x | x | ||

| 4 | Has the ability to resist rust, oxidation, and chemicals in the factory environment. | x | x | ||

| 5 | Easy to install and remove | x | x | ||

| 6 | Many accessories included | x | x | ||

| 7 | Anti-static type available | x |

Applications of polyethylene-coated steel pipes

- Mass production field: Installing conveyor belts, assembling production equipment, etc.

- Applied in water supply and drainage systems because of its anti-oxidation and high-pressure resistance

- Transport of hazardous substances

- Irrigation systems, water pipes in agriculture

- Used in applications such as anti-vibration structures, bridges, etc.

- Gas systems, oil pipelines, etc.

PE coated steel pipe price quote at Bao Tin Steel

The price of polyethylene-coated iron pipes also depends on many factors such as diameter, thickness, and product quality standards as well as market economic fluctuations, … the price of PE-coated steel pipes at Bao Tin Steel ranges from 21,000 – 24,000 VND/Kg. To get the most accurate and fastest product price information, please contact Bao Tin Steel directly at 0932 059 176.

Tiger Steel is a subsidiary of Bao Tin Steel

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ