In modern industrial piping systems, automatic and precise flow control is an essential requirement. The pneumatic butterfly valve is a device designed to meet this requirement, with the ability to open/close quickly, operate via air pressure, and integrate easily into a central control system. The valve is widely used in fields such as water treatment, chemicals, HVAC, food, and oil and gas.

This article will guide you through all the necessary information: from its structure, operating principle, and technical classification to the criteria for choosing a pneumatic butterfly valve before you decide to purchase or install one for your system.

What is a pneumatic control butterfly valve?

A pneumatic butterfly valve is a type of industrial valve that uses air pressure to control the opening, closing, or throttling of fluid flow in a pipeline.

- Mechanical butterfly valve

- Pneumatic actuator

When a control signal is received, the actuator uses air pressure to rotate the valve’s disc by a specific angle—usually 90 degrees—to open or close the flow.

Unlike a traditional lever-operated butterfly valve, the pneumatic valve operates completely automatically, making it suitable for systems that require a fast response, continuous operation, or are located in hard-to-reach areas. This makes it an ideal solution for modern manufacturing environments that demand stability, safety, and high performance in process flow control.

The pneumatic control design offers several distinct advantages over other actuation mechanisms:

- Fast response speed: The valve can open/close completely in just 1–2 seconds, making it suitable for applications that require instantaneous shutoff or emergency handling.

- Comprehensive automation: It can be integrated with central controllers, sensors, PLCs, or SCADA systems for fully automatic operation without manual intervention.

- High safety in hazardous environments: It doesn’t generate sparks like electric control valves, making it ideal for areas prone to fire, explosions, or containing toxic chemicals.

- Cost-effective operation: Compressed air can be reused and is cheaper than electricity in some large-scale applications.

- High reliability: It has fewer mechanical failures, is easy to maintain, and can operate stably for many years with periodic inspections.

With these advantages, the pneumatic butterfly valve is becoming the preferred choice in the industrial automation strategies of many businesses.

Structure & Operating Principle

Structure of the Pneumatic Butterfly Valve

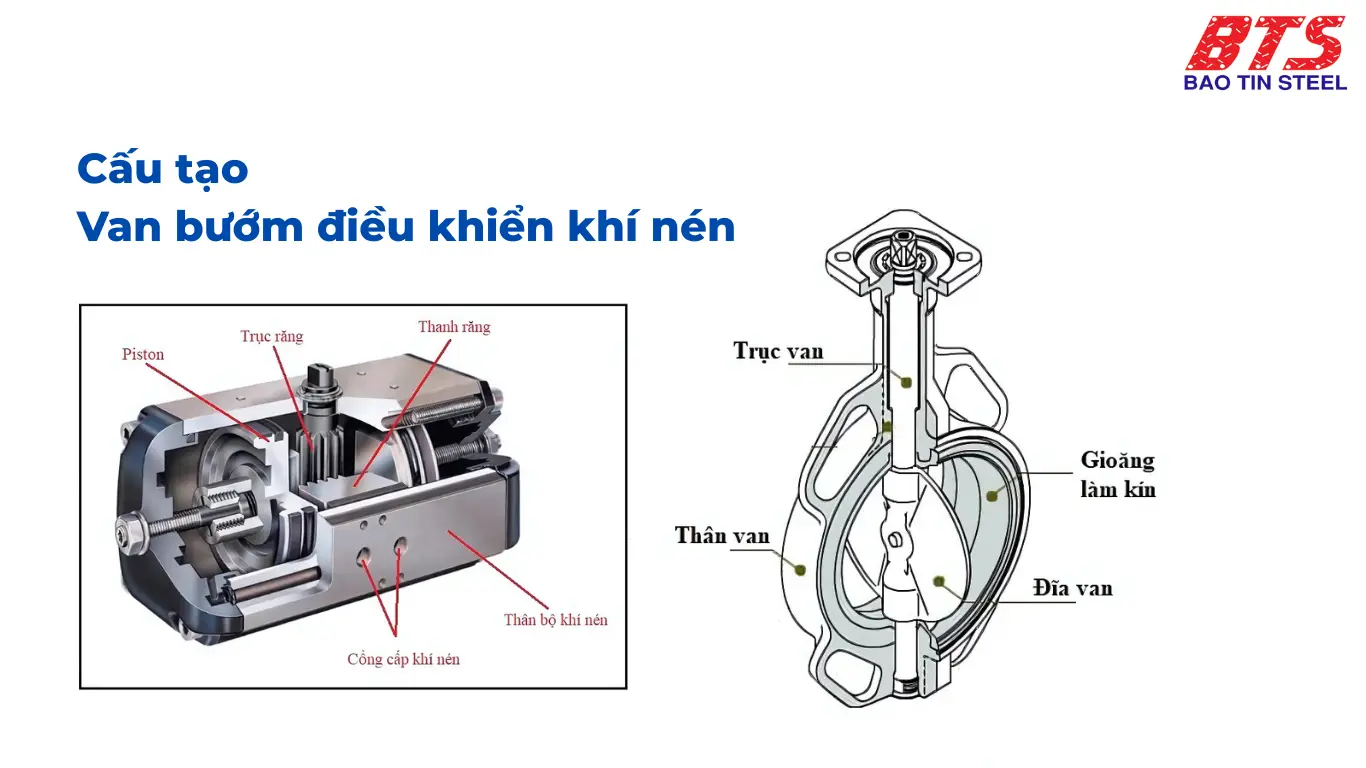

A pneumatic butterfly valve is comprised of two main components:

Pneumatic actuator

This is the “brain” that converts compressed air pressure into mechanical motion to operate the valve. The controller consists of the following components:

- Piston & Cylinder: Compressed air acts on the piston, creating a pushing or pulling force inside the cylinder chamber.

- Rack & Pinion: This mechanism converts the linear motion of the piston into a rotational motion.

- Drive Shaft: Connects to the valve disc, transmitting torque to rotate the valve.

- Return Spring (only on single-acting types): Helps the valve return to its safe position when air pressure is lost.

- Aluminium Alloy Housing: Lightweight, durable, and provides good corrosion resistance.

- Control Accessories (optional): Solenoid valve, limit switch, positioner, which help enhance precision and automation.

Butterfly valve body.

This is the mechanical part that comes into direct contact with the fluid. It consists of:

- Disc: Can rotate 0-90° to regulate or block the flow.

- Body: Made of cast iron, stainless steel, or plastic, with a wafer, lug, or flanged design.

- Stem: Connects the actuator to the valve disc.

- Sealing gasket: Made from EPDM, PTFE, NBR, or metal, ensuring tightness and preventing leakage during operation.

Working principle

The operating principle of the valve is based on compressed air being fed into the actuator, creating a force that pushes the piston, which is then converted into torque that rotates the valve stem:

- When the valve disc rotates parallel to the flow → the valve is fully open.

- When the valve disc rotates perpendicular to the flow → the valve is fully closed.

- When it rotates to an intermediate angle → the flow is throttled.

There are two main operating modes:

- Single-acting: Compressed air opens/closes in one direction, while a spring force is used for the other direction → provides safety when air pressure is lost.

- Double-acting: Compressed air controls both the opening and closing directions → offers more flexible control.

The system can be remotely controlled via electrical signals (4–20 mA or 0–10 V), thanks to the integration of a positioner and a solenoid valve, making it highly suitable for automated SCADA or PLC systems.

Classification of pneumatic control butterfly valves

According to the pneumatic transmission mechanism

Single-Acting

- Characteristics: The valve uses compressed air for only one cycle (typically opening), while the other cycle uses the spring force of a return spring.

- Advantages: It provides safety in case of air pressure loss—the valve automatically returns to its preset “closed” or “open” state (fail-safe).

- Applications: Fire suppression systems, handling hazardous chemicals, or in areas that require a high degree of safety in the event of a power or air supply failure.

Double-Acting

- Characteristics: Requires compressed air to be supplied for both the opening and closing cycles. Does not use a spring.

- Advantages: Provides precise control and a quick response, making it suitable for continuous automation systems.

- Applications: Production lines, water treatment plants, HVAC systems.

By control function

On/Off Valve

- States: Has only two states: fully open or fully closed.

- Control: Controlled by a solenoid valve or an electrical relay signal.

- Suitable for: Applications requiring fast opening/closing, simple control, and no flow regulation.

Modulating / Linear Control Valve

- Adjustment: Continuously adjusts the opening angle based on a voltage signal (0–10V) or a current signal (4–20mA).

- Integration: Includes a positioner to increase control accuracy.

- Suitable for: Chemical mixing systems, water/air flow regulation, and applications requiring precise control.

According to the type of connection to the pipe

| Connection Type | Description | Application |

|---|---|---|

| Wafer | Clamped between two pipe flanges. Popular, compact, and low-cost. | Water plants, HVAC, food industry |

| Lug | Has threaded lugs for bolts, allowing one side of the pipe to be removed easily. | Branching systems, frequent maintenance |

| Flanged | Has flanges on both ends, providing a secure, high-pressure connection. | High-pressure systems, chemical, oil and gas industries |

According to manufacturing materials

| Material | Key Features | Best Suited For |

|---|---|---|

| Cast Iron | Low cost, widely available | Clean water, HVAC |

| Stainless Steel 304/316 | Corrosion-resistant, durable, chemical-resistant | Chemicals, food, seawater |

| Plastic (PVC, UPVC) | Lightweight, corrosion-resistant, inexpensive | Water treatment, mild chemicals |

| Aluminum Alloy | Primarily used for pneumatic actuators, compact, oxidation-resistant | Pneumatic actuators |

Comparison of pneumatically controlled butterfly valves with electrically controlled ones

Both pneumatic and electric butterfly valves are widely used in industrial automation systems. However, each type has its advantages and limitations, which directly impact operational efficiency, cost, and safety. Below is a comparison table to help you choose the valve that best suits your specific needs:

Overview comparison table

| Criteria | Pneumatic Butterfly Valve | Electric Butterfly Valve |

|---|---|---|

| Control Source | Compressed air (4–8 bar pressure) | Electrical voltage (24V, 220V, 380V) |

| Response Speed | Very fast (1–2 seconds) | Medium (5–15 seconds, depending on the motor) |

| Safety in Power Loss | Can be set to a fail-safe position using a spring return mechanism. | Depends on the motor; additional accessories are needed for fail-safe operation. |

| Use in Hazardous Environments (explosive, chemical) | High safety – does not produce electrical sparks. | Higher risk; requires an explosion-proof motor. |

| Flow Regulation | Good (when combined with a linear positioner) | Very good (high-precision linear control) |

| Equipment Cost | Lower within the same segment | Higher, especially for linear motors |

| System Cost (Operation) | Requires investment in a compressed air system | Direct plug-in, easier to deploy |

| Maintenance & Repair | Easy, less prone to failure, fewer electronic components | More difficult, electric motors are sensitive to moisture and dust |

| Durability & Lifespan | High, stable operation in harsh environments | High if the environment is clean and power is stable |

| System Flexibility | High, easy to integrate with SCADA, PLC | Also high, but highly dependent on the motor type |

Which one should I choose?

Choose a pneumatic control valve if:

- You already have a compressed air system in place.

- The application requires fast opening/closing and emergency response.

- The environment poses a risk of explosion or requires absolute safety.

- You prioritise durability, easy maintenance, and a reasonable initial investment cost.

Choose an electric control valve if:

- A compressed air system is not available, and convenience in connection is a priority.

- You require high-precision linear control.

- The valve’s opening/closing frequency is not excessively high throughout the day.

- Installation space is limited (electric valves are often slightly more compact).

Practical application of pneumatic control butterfly valves in industries

Thanks to their fast opening/closing capabilities, automatic operation, and high durability, pneumatic butterfly valves are widely used in many industrial fields. This type of valve is suitable for both systems that require continuous operation and those in particularly harsh environments.

Here are some typical industries that effectively apply this type of valve:

- Controlling flow in pumping stations, clean water plants, reservoirs, and urban drainage systems.

- Applications in conveying chemicals, acids, solvents, or highly corrosive media.

- Regulating the flow of chilled water, hot steam, or air in cooling/chiller systems.

- Used in bottling systems, CIP cleaning, supplying purified water, or controlling temperature during cooking/batch processes.

- Fire Protection and Fighting (PCCC) systems.

- Used in thermal power plants, hydropower plants, or coal mining.

- Used in engine cooling systems, bilge pumps, or seawater supply on ships.

- Medical, pharmaceutical, and laboratory applications.

- Used to control the flow of compressed air, exhaust gas, CO₂, O₂, or specialised technical gases, especially in boiler systems, incinerators, and automated production lines.

Tips for Choosing a Pneumatic Butterfly Valve

To ensure your system operates efficiently, save on maintenance costs, reduce the risk of failures, and extend the system’s lifespan, the first crucial step is to select the correct type of pneumatic butterfly valve.

Based on our journey of supplying industrial valves for over 13 years, here are some tips for choosing the right valve that Thép Bảo Tín has compiled for your reference:

Identify the Media and Operating Conditions

- Type of Fluid: The type of fluid (e.g., water, chemicals, gas, steam, solvents) will determine the valve’s construction material.

- Corrosiveness: If the fluid is acidic, alkaline, or salty, you should choose a stainless steel body, a PTFE-coated disc, or a specialised plastic valve (PVC, CPVC, PVDF).

Working Temperature and Pressure:

- Stainless Steel: Withstands high temperatures and high pressures.

- Plastic: Lightweight and low cost, but has poorer temperature resistance.

Operation Type: ON/OFF vs. Linear Control

- ON/OFF: The valve is either fully open or fully closed, which is suitable for simple applications.

- Linear (Modulating): This requires precise flow control based on an electrical signal (4–20 mA). For this, you should use an additional positioner and a solenoid valve.

Operation Type: ON/OFF vs. Linear Control

- ON/OFF: The valve is either fully open or fully closed, which is suitable for simple applications.

- Linear (Modulating): This requires precise flow control based on an electrical signal (4–20 mA). For this, you should use an additional positioner and a solenoid valve.

Pipe Size & Connection Type

- Nominal Diameter (DN): The valve must match the size of your existing pipeline (e.g., DN50 – DN500).

Connection Type:

- Wafer: Common and low-cost.

- Lug: Convenient for removing one side of the pipeline.

- Flanged: Sturdy, can withstand high pressure, and is used for heavy industrial systems.

Choose a Reliable Brand and Origin

Reputable Valve and Actuator Brands in the Vietnamese Market

Here are some trusted brands for valves and actuators in the Vietnamese market:

- Valves: Wonil, AUT, Kitz, EM-Flow, Samwoo.

- Pneumatic Actuators: Kosaplus, Haitima, Arita, SMC, Festo.

Consider the Budget and System Costs

- Pneumatic valves are typically less expensive than electric valves, but you’ll need to invest in a compressed air system if you don’t already have one.

- Calculate the long-term operating costs (e.g., maintenance, replacement parts, durability).

Latest pneumatic control butterfly valve price quote

The price of pneumatic butterfly valves depends on many technical factors such as: valve diameter (DN), body-disc-gasket material, transmission type (single/double acting), control function (ON/OFF or linear) and manufacturing brand.

Below is the latest reference price list, updated in June 2025:

| Valve Type | Size (DN) | Price (VNĐ) |

|---|---|---|

| Pneumatic Cast Iron Butterfly Valve – ON/OFF | DN50 | 1,600,000 – 2,200,000 |

| DN100 | 2,800,000 – 3,400,000 | |

| DN150 | 4,200,000 – 5,500,000 | |

| Pneumatic Stainless Steel 304 Butterfly Valve – Double-Acting | DN50 | 2,900,000 – 3,500,000 |

| DN100 | 4,500,000 – 5,800,000 | |

| DN150 | 6,800,000 – 8,500,000 | |

| Pneumatic UPVC Plastic Butterfly Valve – Single-Acting | DN50 – DN100 | 2,000,000 – 4,000,000 |

| Pneumatic Linear Control Valve | DN50 – DN150 | Add 2–3 million/positioner |

Note: Prices may vary depending on the brand, accompanying accessories (solenoid valve, limit switch, positioner, etc.), order quantity, and specific project requirements.

=> See more: Latest butterfly valve price list 2025

Price of accessories included

| Accessories | Reference Price (VNĐ) |

|---|---|

| Solenoid Valve 5/2, 5/3 (24V/220V) | 350,000 – 750,000 |

| Limit Switch Box | 650,000 – 1,200,000 |

| Linear Positioner | 2,500,000 – 4,500,000 |

| Air Hose, Air Connectors, Stainless Steel Fittings | Varies by configuration |

Conclusion

Pneumatic butterfly valves are an effective, safe, and economical automation solution for modern industrial systems. With their compact design, fast operation, high durability, and flexible control capabilities, these valves are a preferred choice in many industries, from water treatment, chemicals, and HVAC to food, power, and shipbuilding.

However, to select the correct valve for your system—considering factors like material, actuator type, and control accessories—you need accurate technical consultation and clear pricing from a reputable supplier.

Bao Tin Steel specialises in supplying a wide range of industrial valves, including gate valves, ball valves, butterfly valves, safety valves, and Y-strainers. We carry products from reputable domestic and international brands such as Shin Yi, ROBO, Minh Hòa, YDK, and Giacomini.

Contact Bao Tin Steel now for detailed consultation and pricing.

-

- Hotline: 0932 059 176

- Email: bts@thepbaotin.com

Tiger Steel is a subsidiary of Bao Tin Steel.

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ