ROBO Spring-Loaded Silent Check Valve (SCV)

The ROBO Spring-Loaded Check Valve (Silent Check Valve – SCV) is a key component in piping systems, designed to prevent backflow and protect pumps and industrial equipment. With a robust construction made from ductile iron, stainless steel 304, and EPDM rubber, the product ensures excellent tightness, smooth operation, and long-lasting performance across various working environments.

Manufactured according to international standards BS EN 1074-3 and BS EN 558-1, the ROBO SCV can withstand a pressure rating of PN10/16 and operate within a temperature range of -10°C to 80°C. It is ideal for water supply and drainage systems, HVAC, firefighting (FACP), and other industrial applications—a reliable and cost-effective solution that enhances pipeline efficiency and minimises maintenance costs.

ROBO Silent Check Valve

ROBO Silent Check Valve

Outstanding Features of the ROBO Spring-Loaded Check Valve

The ROBO check valve stands out for its combination of advanced engineering design and durable materials. Its key features include:

- Effective backflow prevention: The spring-loaded mechanism enables quick response, preventing reverse flow that could damage pumps or equipment.

- Quiet operation: The Silent Check Valve design minimizes noise and water hammer in the pipeline.

- High-quality materials:

-

Body: Ductile Iron ASTM A536

-

Shaft & Spring: Stainless Steel 304

-

Disc: EPDM-coated for superior sealing and corrosion resistance.

-

- Multiple connection standards: Compatible with BS4504, DIN 2632, and DIN 2633, ensuring easy installation across different systems.

- Stable pressure and temperature performance: Operates effectively within PN10/16 pressure range and -10°C to 80°C temperature range.

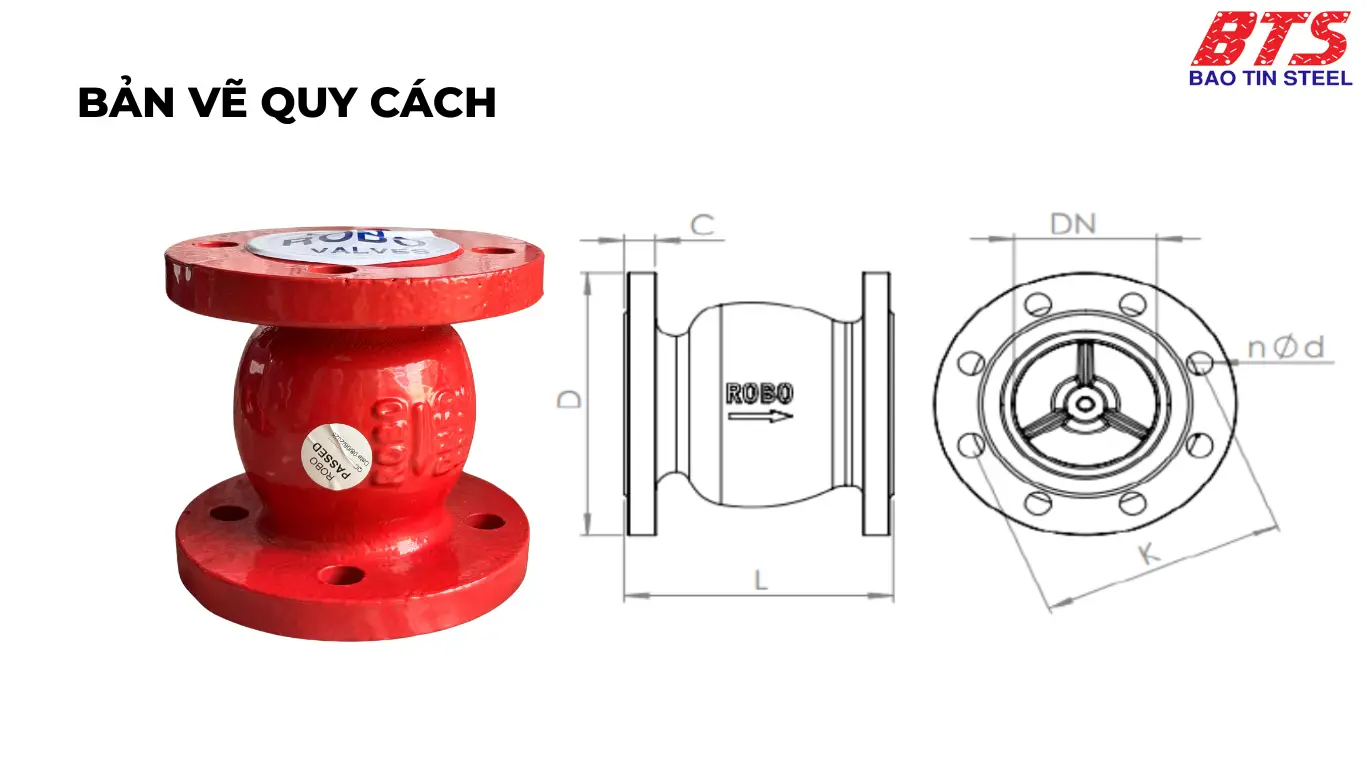

ROBO one-way valve specification drawing

ROBO one-way valve specification drawing

Technical Specifications

| Item | Specification |

|---|---|

| Design Standard | BS EN 1074-3 |

| Face-to-Face | BS EN 558-1 |

| Connection Standards | BS4504, DIN 2632, DIN 2633 |

| Working Pressure | PN10/16, JIS10K |

| Working Temperature | -10°C ~ 80°C |

| Body Material | Ductile Iron ASTM A536 |

| Disc | EPDM-coated Ductile Iron |

| Shaft & Spring | Stainless Steel 304 |

| Stopper | Brass ASTM B824 |

Available Sizes: DN50 – DN300

(Detailed dimension tables available in the ROBO Valve Catalogue.)

Applications

Thanks to its modern design and reliable anti-backflow function, the ROBO SCV is widely used in industrial and civil systems, including:

- Urban water supply and drainage systems – Prevent reverse flow and contamination.

- Pumping stations – Protects pumps, pipelines, and auxiliary equipment from back pressure.

- Firefighting systems (FACP) – Ensures a stable, ready water supply without leakage.

- HVAC systems – Maintain steady fluid flow in chilled or hot water circuits, improving energy efficiency.

- Industrial manufacturing – Ideal for controlling the flow of water, oil, and process fluids.

Economic Benefits

The ROBO check valve not only delivers high performance and durability but also provides significant cost advantages:

- Reduced maintenance and repair costs due to leak-free, automatic spring closure design.

- Extended equipment lifespan by protecting pumps and pipelines from reverse pressure.

- Energy efficiency through optimised flow structure and minimal pressure loss.

- Investment optimisation with a wide range of sizes (DN50–DN300) suitable for various systems.

- Long-term reliability thanks to premium materials and adherence to international standards.

Installation and Maintenance Guide

Before installation:

- Inspect the valve for cracks or deformation.

- Clean flange surfaces and remove debris.

Installation steps:

-

Position the valve between two flanges, ensuring the arrow on the valve body aligns with the flow direction.

-

Centre the valve properly to avoid misalignment.

-

Place gaskets on both ends and tighten bolts in a star pattern for even pressure.

Post-installation checks:

- Test the valve’s open/close movement manually.

- Run water flow to ensure no leakage.

Maintenance recommendations:

- Inspect every 3–6 months, depending on service conditions.

- Clean the valve disc, spring, and EPDM seal if debris accumulates.

- Replace worn components with genuine parts when necessary.

- Test the valve operation before resuming full system service.

Following these steps ensures optimal performance, durability, and minimised maintenance costs over time.

Conclusion

The ROBO Spring-Loaded Silent Check Valve (SCV) offers a durable, quiet, and efficient solution for water supply, HVAC, firefighting, and industrial systems. It provides reliable backflow prevention, economic efficiency, and long service life—making it a top choice for engineers and project managers.

For genuine ROBO valves (DN50–DN300) at competitive prices, contact Bao Tin Steel, an authorised distributor:

📞 Hotline: 0932 059 176

📧 Email: bts@thepbaotin.com

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ