The Shin Yi gear-operated butterfly valve is one of the most popular products today for water supply and drainage systems, fire protection (PCCC), and wastewater treatment. With a sturdy design, high sealing performance, and exceptional durability, the Shin Yi gear-operated butterfly valve not only meets international technical standards but also provides optimal economic efficiency for both industrial and residential projects.

The Shin Yi brand, originating from Taiwan, is renowned for high-quality valves. Among its most popular gear-operated butterfly valves are the wafer type and the flanged type. Each type has distinct construction, specifications, and applications, making them suitable for specific installation conditions.

This article will help you distinguish between these two product lines and provide the latest price updates for 2025.

Types of Shin Yi Gear-Operated Butterfly Valves

Wafer Gear-Operated Butterfly Valve

The Shin Yi wafer gear-operated butterfly valve is a popular product designed to be installed between two pipe flanges. Thanks to its compact design, easy installation, and reasonable price, this type of valve is widely used in water supply systems, wastewater treatment, fire protection (PCCC), and HVAC (heating, ventilation, and air conditioning) systems.

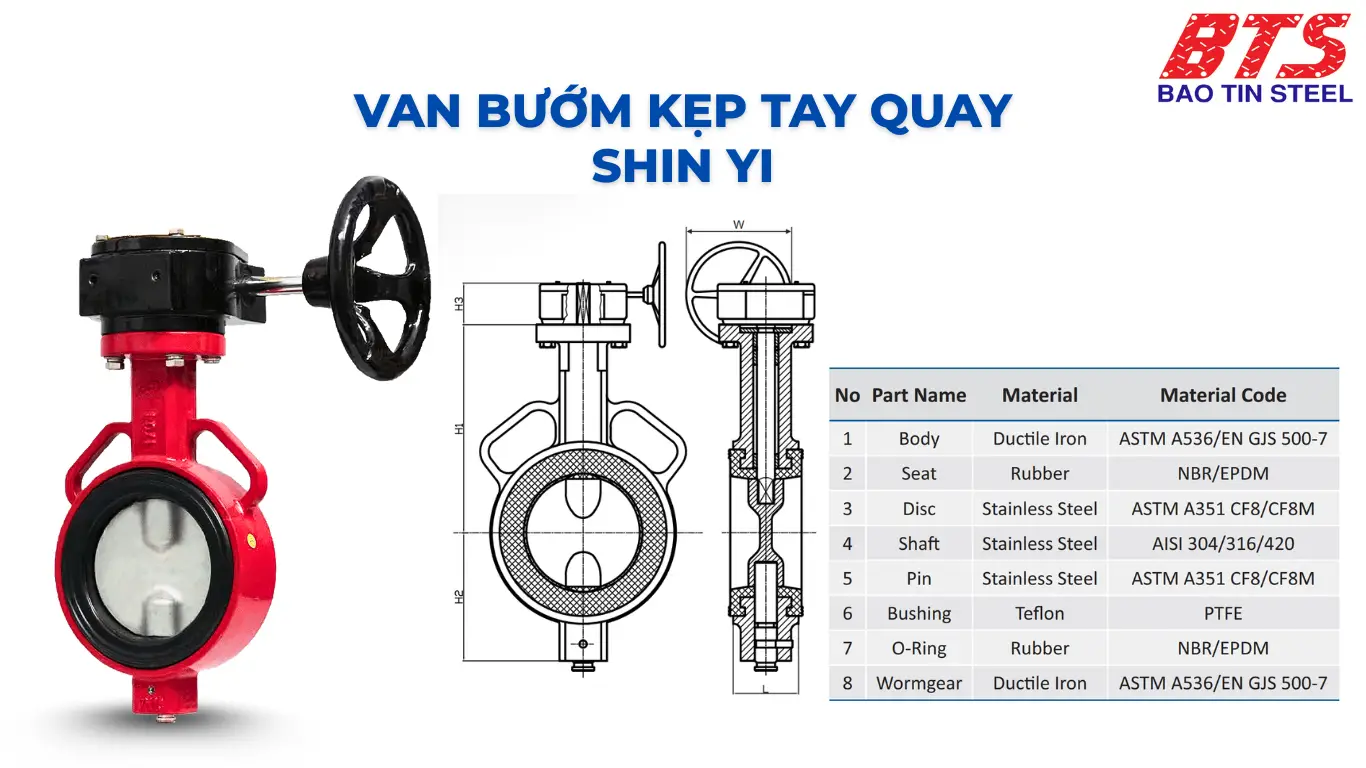

Design and Appearance

The valve features a wafer-style design, compact and convenient for installation between two pipe flanges. The valve body is made of high-quality Epoxy-coated cast iron, available in blue or red, providing excellent corrosion resistance and durability under harsh environmental conditions.

The handwheel is designed as a large wheel, connected to a cast-iron gearbox mounted on top of the valve body, ensuring smooth operation and easy flow control. The black sealing gasket (usually EPDM or NBR) lines the inside of the valve body, working together with the 304/316 stainless steel disc to deliver high sealing performance, prevent leakage, and extend service life.

Two integral lifting lugs on either side of the valve body not only assist with positioning during installation but also enhance structural strength for use in high-pressure systems.

Detailed Technical Specifications

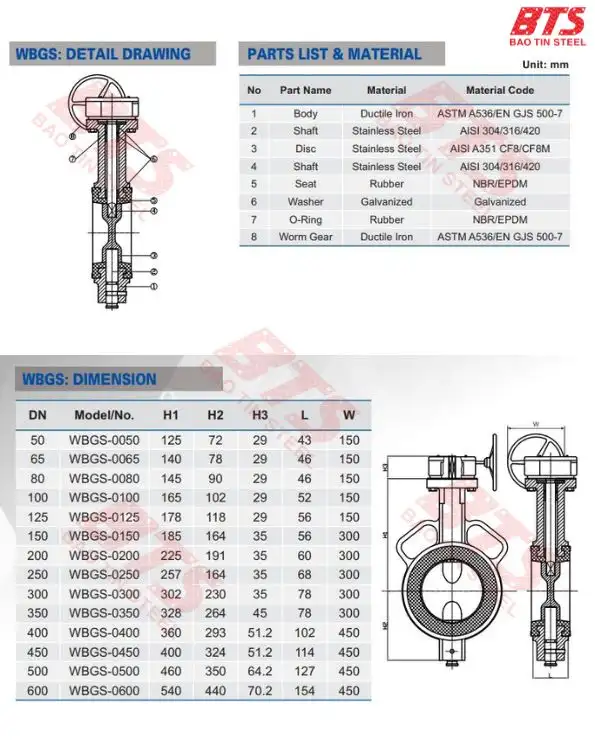

Specifications – Shin Yi Wafer Gear-Operated Butterfly Valve

- Brand: Shin Yi

- Origin: Taiwan

- Size range: DN50 – DN600

- Design standards: BS 5155 / API 609

- Connection type: Wafer

- Actuator mounting: ISO 5211

- Connection & pressure standards:

- BS 4504, DIN 2632 (PN10, PN16, PN25)

- JIS B2220 (10K, 16K)

- ASME B16.42 (150LB)

- Colour options: Blue – Red

- Operating temperature: -10°C to 80°C

- Working environment: Water systems

Key Advantages

- Compact design, easy to install in limited space areas.

- Handwheel with gearbox allows precise operation with reduced manual effort.

- Excellent sealing performance, minimising fluid leakage.

- Cost-effective, reducing initial investment.

- Easy maintenance and replaceable components.

Applications

The Shin Yi wafer gear-operated butterfly valve is widely used in:

- Domestic and industrial water supply & drainage systems

- Building and factory fire protection (PCCC) systems

- Wastewater treatment lines

- HVAC – central air conditioning systems

Shin Yi Flanged Gear-Operated Butterfly Valve

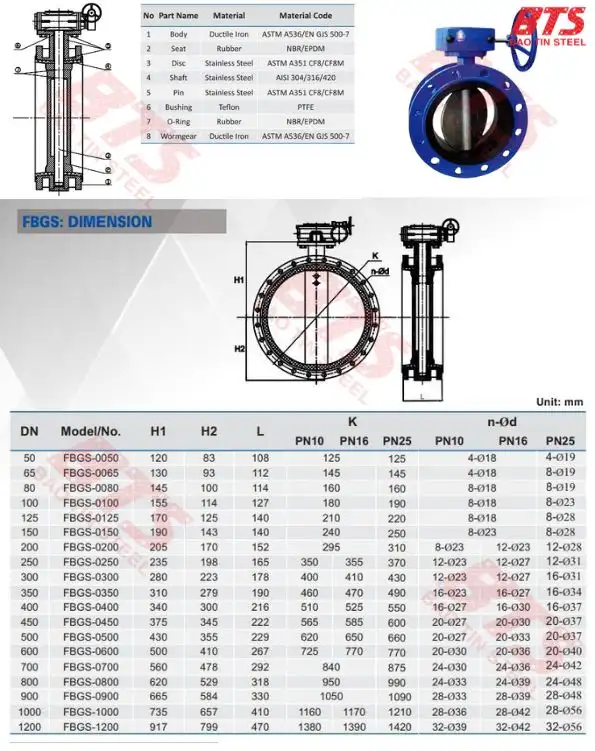

The Shin Yi flanged gear-operated butterfly valve is specially designed for piping systems that require high strength and high working pressure. With a double-flanged design, the valve can be securely bolted to the pipeline, ensuring absolute sealing and minimizing vibration during operation.

Design and Appearance

The valve features a robust, large-sized design with a strong and durable construction. The valve body is made of high-quality ductile iron, coated with blue Epoxy paint for effective corrosion resistance in water, steam, and mild chemical environments.

The valve disc is made of stainless steel 304 or 316, providing excellent wear resistance and mechanical strength. The internal black EPDM sealing gasket fits tightly around the disc, ensuring high sealing performance. The gear-operated handwheel assembly is mounted on top of the valve body and paired with a large black-painted steel handwheel, allowing smooth operation even for large sizes such as DN400–DN600.

The flanges are integrally cast with the valve body, with fully machined bolt holes according to JIS, BS, or ANSI standards, ensuring high precision and compatibility with common piping connections.

Basic Technical Specifications

Shin Yi Flanged Gear-Operated Butterfly Valve

- Brand: Shin Yi

- Origin: Taiwan

- Size range (DN): DN50 – DN1200

- Design standards: BS 5155 / API 609

- Connection type: Flanged

- Actuator mounting: ISO 5211

- Connection & pressure standards:

- BS 4504, DIN 2632 (PN10, PN16, PN25)

- JIS B2220 (10K, 16K)

- ASME B16.42 (150LB)

- Colour options: Blue – Red

- Operating temperature: -10°C to 80°C

- Working environment: Water systems

Key Advantages

- Strong flanged connection, suitable for high-pressure piping systems.

- High load and wear resistance, especially with stainless steel disc and premium EPDM gasket.

- Smooth operation thanks to gear-operated handwheel with torque-assist gearbox.

- Suitable for large diameters ranging from DN50 to DN1200.

Applications

The Shin Yi flanged gear-operated butterfly valve is widely used in:

- Clean water supply systems for factories and industrial zones

- Industrial and domestic wastewater treatment lines

- High-standard fire protection (PCCC) systems

- Industries such as chemicals, food processing, cement, and metallurgy

Latest Shin Yi handwheel butterfly valve price list [Updated 2025]

The prices below are for reference only and apply to genuine Shin Yi products – made in Taiwan, including the handwheel and gearbox. Prices may vary depending on order quantity, gasket material (EPDM/NBR/Teflon), or market fluctuations.

Shin Yi Wafer Gear-Operated Butterfly Valve

| Nominal Diameter (DN) | Reference Price (VND) |

| DN50 |

650.000 – 750.000

|

| DN65 |

750.000 – 850.000

|

| DN80 |

900.000 – 1.050.000

|

| DN100 |

1.100.000 – 1.250.000

|

| DN125 |

1.350.000 – 1.500.000

|

| DN150 |

1.650.000 – 1.800.000

|

| DN200 |

2.400.000 – 2.800.000

|

| DN250 |

3.800.000 – 4.300.000

|

| DN300 |

5.000.000 – 5.500.000

|

| DN350 |

6.800.000 – 7.400.000

|

| DN400 |

8.800.000 – 9.500.000

|

| DN450 |

11.000.000 – 12.000.000

|

| DN500 |

13.500.000 – 14.500.000

|

| DN600 |

18.000.000 – 19.500.000

|

Shin Yi Flanged Gear-Operated Butterfly Valve

| Nominal Diameter (DN) | Reference Price (VND) |

| DN50 |

1.100.000 – 1.250.000

|

| DN65 |

1.250.000 – 1.400.000

|

| DN80 |

1.450.000 – 1.650.000

|

| DN100 |

1.800.000 – 2.000.000

|

| DN125 |

2.200.000 – 2.400.000

|

| DN150 |

2.800.000 – 3.100.000

|

| DN200 |

4.600.000 – 5.000.000

|

| DN250 |

6.300.000 – 6.800.000

|

| DN300 |

8.500.000 – 9.200.000

|

| DN350 |

11.000.000 – 11.800.000

|

| DN400 |

13.800.000 – 14.500.000

|

| DN450 |

17.000.000 – 18.500.000

|

| DN500 |

20.000.000 – 22.000.000

|

| DN600 |

26.000.000 – 28.500.000

|

| DN700 – DN1000 |

Liên hệ báo giá dự án

|

| DN1200 |

Liên hệ báo giá dự án

|

Contact Hotline 0932 059 176 to receive project-based discounted pricing and free technical support!

Based on the Working Environment

- Clean water, domestic water: Wafer gear-operated butterfly valve

- Fire protection systems (sprinklers, pumps): Wafer or flanged type (depending on pressure and scale)

- Wastewater, sludge: Prefer flanged valves with high-quality EPDM/NBR gaskets

- Mild chemicals, dilute acids: Valves with stainless steel 316 disc and Teflon (PTFE) gasket

- HVAC / central air conditioning systems: Wafer gear-operated butterfly valve

Based on Pipe Pressure and Size

- Pipes < DN300, pressure PN10–PN16 → Use wafer gear-operated butterfly valves for cost efficiency and easier installation.

- Pipes DN350 and above, or high pressure > PN16 → Use flanged gear-operated butterfly valves to ensure stability and safe operation.

Consider Installation Space

- Tight space, small technical cabinets, or quick maintenance required → Wafer type is the practical choice.

- Fixed installation, vibration, or large-diameter pipes → Flanged type is recommended for secure bolting and better load resistance.

Material Requirements

- Valve body: Ductile iron (durable, cost-effective)

- Valve disc: Stainless steel 304 (normal water), stainless steel 316 (corrosive media)

- Sealing gasket: EPDM (clean water), NBR (light oils)

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ