With their superior corrosion resistance and beautiful appearance, stainless steel squares are increasingly used in many areas of life. So what are stainless steel squares? What are their characteristics? Or what is the price? If you are interested and want to buy this type of square steel, you should not miss the article below.

Technical specifications of stainless steel square tube

Product size:

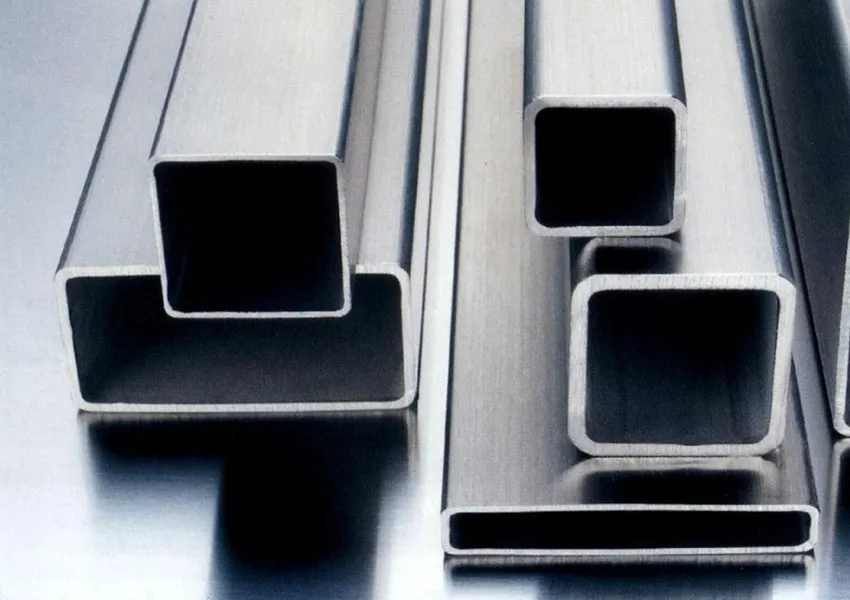

- Square tube (mm): 10.0 x 10.0, 12.7 x 12.7, 15.0 x 15.0, 20.0 x 20.0, 25.0 x 25.0, 30.0 x 30.0, 40.0 x 40.0, 50.0 x 50.0

- Rectangular tube (mm): 10.0 x 20.0, 10.0 x 40.0, 13.0 x 26.0, 15.0 x 30.0, 20.0 x 40.0, 25.0 x 50.0, 30.0 x 60.0, 30.0 x 90.0, 40.0 x 80.0

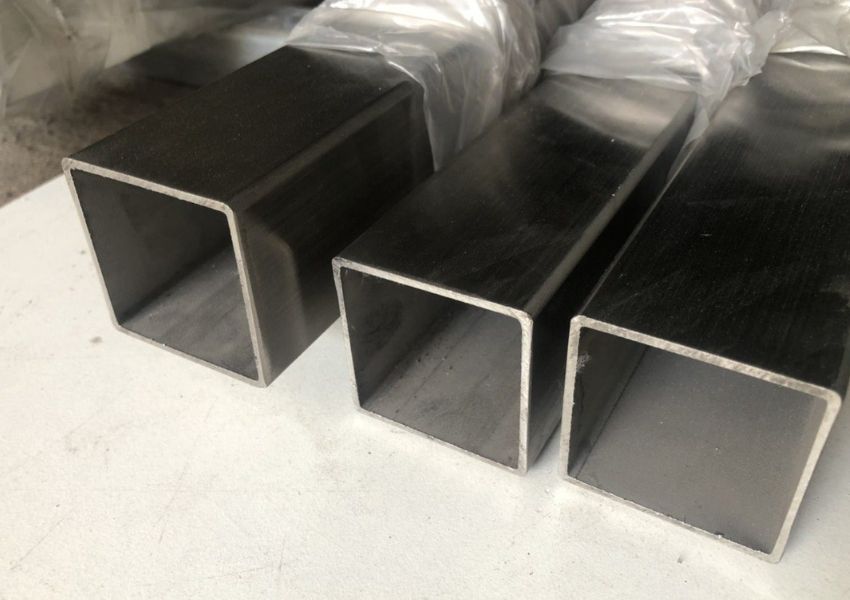

What is a stainless steel square tube?

Made from stainless steel 304/201/316, a stainless steel square tube has a tube-like shape. Its cross-section is square or rectangular with many different sizes.

Common types of stainless steel square tubes

To classify stainless steel square tubes, people rely on two main factors: material and purpose of use. Specifically:

Classification based on steel material

There are many types of stainless steel such as 304 stainless steel, 201 stainless steel, and 316 stainless steel. Each type has a different chemical composition and properties. Therefore, when used to create stainless steel squares, they also have their characteristics. They are also used in specific applications:

304 stainless steel tube

304 stainless steel square tube

This is the most commonly used square steel line, including 2 main types: 304L stainless steel and 304H stainless steel. 304L stainless steel has a lower carbon content than 304H stainless steel. Therefore, the price of this type of square steel is also slightly lower than that of 304H. 304 square steel has many great advantages, such as:

- Good corrosion resistance even in harsh environments such as humidity, seawater, chemicals, etc.

- 304 stainless steel has an austenite crystal structure, providing high durability and good bearing capacity.

- 304 stainless steel square iron can withstand high temperatures without deformation.

- This square iron has a shiny, dirt-free surface, suitable for many projects requiring aesthetics.

201 stainless steel square tube

Compared with 304 stainless steel square tubes, this type of square tube has higher hardness. However, its corrosion resistance is slightly worse. 201 stainless steel square tube contains 7.1% manganese and 4.5% nickel. At the same time, it can withstand temperatures between 1,149 and 1,232 °C.

316 stainless steel square tube

Classification based on purpose of use

Based on the product’s uses, stainless steel square tubes are divided into 2 types: stainless steel square tubes used for decoration and stainless steel square tubes used in industry.

- In decoration. Used in home decoration, interior and exterior, household appliances, etc.

- In industry. Applied in chemical plants, houses, businesses, maritime industry, shipbuilding, etc.

Chemical composition and mechanical properties of steel grade

304 stainless steel square tube

Steel grade specifications:

| Ingredient | Concentration % |

| C | Max 0.08 |

| Cr | 18 – 20 |

| Fe | 66.345 – 74 |

| Mn | Max 2 |

| Ni | 8 – 10.5 |

| P | Max 0.045 |

| S | Max 0.03 |

| Si | Max 1 |

មើលផលិតផលដែកអ៊ីណុកផ្សេងទៀត៖

លក្ខណៈមេកានិចនៃថ្នាក់ដែក៖

| Physical properties | Metric system | Pounds | Note |

| Proportion | 8 g/cc | 0.289 lb/in³ | |

| Mechanical properties | |||

| Brinell hardness | 123 | 123 | Estimated value based on Rockwell B hardness |

| Knoop hardness | 138 | 138 | Estimated value based on Rockwell B hardness. |

| Rockwell B hardness | 70 | 70 | |

| Vickers hardness | 129 | 129 | Estimated value based on Rockwell B hardness. |

| Tensile stress | 505 MPa | 73200 psi | |

| Yield stress | 215 MPa | 31200 psi | At 0.2% offset |

| Elongation | 70 % | 70 % | ở 50 mm |

| Elastic modulus | 193 – 200 GPa | 28000 – 29000 ksi | |

| Poisson’s ratio | 0.29 | 0.29 | |

| Impact force Charpy | 325 J | 240 ft-lb | |

| Shear force | 86 GPa | 12500 ksi | |

| Electric | |||

| Resistivity | 7.2e-005 ohm-cm | 7.2e-005 ohm-cm | At 20°C (68°F); 1.16E-04 Tại 650°C (1200°F) |

| Magnetic properties | 1.008 | 1.008 | Tại RT |

| Thermal properties | |||

| CTE, linear at 20°C | 17.3 µm/m-°C | 9.61 µin/in-°F | At 0-100°C |

| CTE, linear at 250°C | 17.8 µm/m-°C | 9.89 µin/in-°F | At 0-315°C (32-600°F) |

| CTE, linear at 500°C | 18.7 µm/m-°C | 10.4 µin/in-°F | At 0-650°C |

| Heat capacity | 0.5 J/g-°C | 0.12 BTU/lb-°F | From 0-100°C (32-212°F) |

| Thermal conductivity | 16.2 W/m-K | 112 BTU-in/hr-ft²-°F | At 0-100°C, 21.5 W/m°C at 500°C |

| Melting temperature | 1400 – 1455 °C | 2550 – 2650 °F | |

| Solidus | 1400 °C | 2550 °F | |

| Liquidus | 1455 °C | 2650 °F | |

ដែកជ្រុងអ៊ីណុក 316

លក្ខណៈបច្ចេកទេសនៃថ្នាក់ដែក៖

| Ingredient | Wt. % |

| C | 0.08 |

| Cr | 17 |

| Fe | 65 |

| Mn | 2 |

| Mo | 2.5 |

| Ni | 12 |

| P | 0.045 |

| S | 0.03 |

| Si | 1 |

Mechanical properties of steel grade:

| Physical properties | Metric system | Pounds | Note |

| Proportion | 8 g/cc | 0.289 lb/in³ | |

| Mechanical properties | |||

| Brinell hardness | 149 | 149 | |

| Knoop hardness | 169 | 169 | Estimated value based on Brinell hardness |

| Rockwell B hardness | 80 | 80 | |

| Vickers hardness | 155 | 155 | Estimated value based on Brinell hardness |

| Tensile stress | 550 MPa | 79800 psi | |

| Yield stress | 240 MPa | 34800 psi | |

| Elongation | 60 % | 60 % | in 50 mm |

| Elastic modulus | 193 GPa | 28000 ksi | |

| Charpy impact force | 105 J | 77.4 ft-lb | V-notch |

| Izod impact force | 129 J | 95.1 ft-lb | |

| Electrical characteristics | |||

| Resistivity | 7.4e-005 ohm-cm | 7.4e-005 ohm-cm | At 20ºC |

| Magnetic properties | 1.008 | 1.008 | At RT |

| Thermal properties | |||

| CTE, linear at 20°C | 16 µm/m-°C | 8.89 µin/in-°F | 0 – 100ºC |

| CTE, linear at 250°C | 16.2 µm/m-°C | 9 µin/in-°F | Tại 0-315°C (32-600°F) |

| CTE, linear at 500°C | 17.5 µm/m-°C | 9.72 µin/in-°F | 0 – 540ºC |

| Nhiệt dung | 0.5 J/g-°C | 0.12 BTU/lb-°F | Từ 0-100°C (32-212°F) |

| Tính dẫn nhiệt | 16.3 W/m-K | 113 BTU-in/hr-ft²-°F | 100ºC |

| Nhiệt độ nóng chảy | 1370 – 1400 °C | 2500 – 2550 °F | |

| Solidus | 1370 °C | 2500 °F | |

| Liquidus | 1400 °C | 2550 °F | |

Advantages and applications of stainless steel square tube

For 316 stainless steel square tubes.

Characteristics: Molybdenum content increases resistance to marine environments. High creep strength at elevated temperatures and good heat resistance. Biocompatible. Fabrication characteristics are similar to Grades 302 and 304.

Applications: Food and pharmaceutical processing equipment, marine exterior trim, surgical implants, and industrial equipment handling corrosive process chemicals used in the manufacture of inks, rayon, photographic chemicals, paper, textiles, bleaches, and rubber.

Corrosion resistance: better corrosion resistance than 302 and 304; resistant to sodium and calcium salts; hypochlorite solutions; phosphoric acid; and sulfite liquors and sulfuric acids used in the pulp industry.

For 304 stainless steel square tubes.

Corrosion resistance: resists most oxidizing acids and salt spray.

Tiger Steel is a subsidiary of Bao Tin Steel

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ