Steel plate processing services (cutting, bending, stamping, etc.) on request

You are looking for a unit that processes steel plates according to your requirements, but you have not found a reputable place with reasonable prices and guaranteed quality. Then you can visit Bao Tin Steel! We specialize in cutting, bending, stamping, punching, etc. steel plates professionally, with high precision and competitive prices compared to the market.

Bao Tin Steel provides steel plate processing services in Ho Chi Minh City

Bao Tin Steel is a unit specializing in processing steel plates in Ho Chi Minh City and nationwide, meeting all customer needs with the following services:

- Cutting steel plate according to requirements

- Bending steel plate according to requirements

- Stamping steel plate according to requirements

- Punching steel plate according to requirements

- Bending steel plate according to requirements

- Welding finished steel plate according to requirements

Steel plate cutting service on request

Bao Tin Steel sheet metal cutting services include:

- Processing and cutting steel plates 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, …. to 100mm with steel grades imported from Korea, China, Russia, USA, … such as steel grades SS400, CT3, Q345B, C45, A36, AH36, A572, Q235,…

- Cutting corrugated iron plates according to requirements

- Cutting steel bars according to requirements

- Cutting code plates according to customer requirements

- Cutting steel plates for mold manufacturing technology, machinery, equipment, etc.

If we talk about cutting steel plates, there are many methods. For example: manual cutting, manual cutting with hand-held machines, etc. However, these cutting technologies do not bring high efficiency in terms of quality as well as product processing time.

At Bao Tin Steel, we cut steel plates using CNC cutting technology. The advantage of CNC technology is the ability to cut quickly and accurately and cut steel with high thickness. Depending on the thickness, our company can cut using different methods. You can learn to choose the appropriate cutting method.

1. Oxy – Gas

–Advantage:

- Can cut thick steel plates, can cut up to 150mm thick

- Low cost

– Disadvantages:

- Not very aesthetic, the thicker the steel plate, the greater the bevel.

2. Plasma

– Advantage:

- Cuts thick metals

- Plasma cutting speed is faster than oxy-gas cutting when performed with steel plates under 50mm thick. Faster than laser cutting when performing with plates thicker than 3mm. Fast cutting speed, increasing efficiency.

– Disadvantages:

- Electrodes, cutting nozzles, and spray nozzles must be replaced frequently, increasing product costs.

3. Laser

– Advantage:

- Cuts most metals and non-metals

- For high precision, complex details

- Highly aesthetic, thanks to the decisive, fast, and precise cutting line

– Disadvantages:

- Its price is also quite high.

>> When you contact Bao Tin Steel to ask about the service of cutting steel plates on demand. You will be enthusiastically advised by staff about steel grades and suitable steel-cutting methods. In particular, the price is good but still ensures aesthetics, quality, and on-time delivery. Not yet; the size of the steel plate is completely cut according to your wishes.

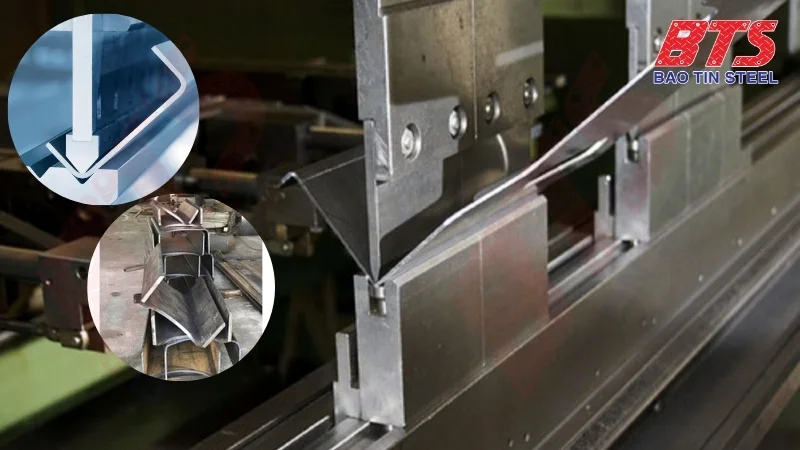

Steel plate stamping and bending service on request

Bao Tin Steel accepts to process and stamp steel plates according to specifications, sizes, drawings of U, V, C, and Z shapes, or other specifications that customers choose:

-

Steel thickness: 3mm, 4mm, 5mm, 6mm, 8mm, 10mm,… to 100mm with steel plate grades SS400, CT3, C45, Q345, A572, Q235,….

-

Frame: According to the customer’s requirements, specifications, drawings

A CNC press brake is used to process sheet metal structures of relatively large sizes. Currently, the company’s products are mainly processed by CNC press brake. Because there are many advantages:

- Fast speed, short time, stable and continuous processing

- High precision punching

- Bending in large quantities, many times faster than manual work

- Strong punching force, no loss of corners of parts

- Diverse processing of materials

Steel plate processing process according to requirements at Bao Tin Steel

Bao Tin Steel processes steel plates clearly and professionally. So what are the processing steps? Below are the 11 most basic and necessary steps for your reference, as follows:

- Step 1: Receive the processing request from a customer

Bao Tin Steel receives customer requests for steel plate processing needs. Our company’s staff will compile requests to create or receive customer drawings..

- Step 2: Customer consultation

Bao Tin Steel staff will advise customers on steel grades, steel plate standards, and appropriate processing methods.

- Step 3: Agree on requirements

After completing the process of reviewing the customer’s design file, we will agree on the requirements and proceed to quote and receive the order deposit.

- Step 4: Customer deposits

After the customer deposits as agreed, Bao Tin Steel will process it according to the design drawing.

- Step 5: Cut the steel plate

In this step, the flat metal sheet is machined on a cutting machine programmed according to the drawing.

- Step 6: Punching steel plate

For details that need punching, a CNC metal punching machine is needed. The punching machine has many different types of cutters; depending on the customer’s drawing requirements, Bao Tin Steel chooses the appropriate cutter.

- Step 7: Bending steel plate

The parts have been machined according to the drawing, the edges are bent to increase stiffness, and the parts can be assembled. The bending machine needs to adjust the angle. The punching cutter also needs to be selected to be compatible with the part to be bent.

- Step 8: Welding the parts

For accessories with additional assembly details that require the help of a welding machine, Bao Tin Steel will weld the details. After welding, the welds will be polished before moving to the next processing stage.

- Step 9: Material surface treatment

Steel materials, after processing, will be galvanized, powder coated, etc. according to requirements. With stainless steel, the welds need to be smoothed and polished so that they are not exposed.

- Step 10: Assemble the parts to create the finished product

After going through the above stages, Bao Tin Steel will gather to assemble into complete products according to requirements. The products when installed must be skilled, not peeled, and must meet factory standards.

- Step 11: Check product quality, pack, and deliver to customer

All products at Bao Tin Steel are carefully inspected before being delivered to customers, avoiding cases of defective products being returned, reducing the company’s reputation as well as wasting customers’ time.

>> The process is like that; however, not all sheet metal processing products require going through all the above steps but may require less depending on the product design and finished product requirements.

Price list for steel plate processing according to requirements at Bao Tin Steel

Depending on the technical requirements of specifications, aesthetics, complexity, delivery time, and order quantity, the price of steel plate processing at Bao Tin Steel will change. Our company provides quality steel plate processing services at good prices on the market today.

Below is the price list for steel plate processing according to requirements at Bao Tin Steel:

Note on price list: The above processing price may not be fixed and depends on many factors. Please contact Bao Tin Steel for advice and a quotation.

If you still have questions or need more detailed answers about custom steel plate processing, please contact Bao Tin Steel for the fastest advice and support.

Tiger steel is a branch of Bao Tin Steel

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ