Are you looking for a way to control flow rate in a system while ensuring the flow only moves in one direction? The throttle check valve is exactly the solution you need. Not only does it allow for precise flow rate adjustment, but it also incorporates a check valve function to prevent reverse flow—delivering optimal safety and efficiency for hydraulic, pneumatic, or HVAC systems.

In this article, Bao tin Steel will guide you through the structure, working principle, selection, and proper installation techniques to help you maximise the benefits of a one-way throttle valve.

Let’s get started!

What is a Throttle check valve?

A Throttle check valve is a specialised industrial device designed to control the flow of liquid or gas in a single direction while preventing reverse flow. Simply put, it is a smart combination of a throttle valve (for adjusting flow rate) and a check valve (which only allows flow in one direction).

The key advantage of a one-way throttle valve lies in its dual functionality: it can regulate the flow rate in one direction while allowing free, unobstructed flow in the opposite direction. This simplifies system design, reduces the number of valves required, minimises potential leakage points, and optimises investment costs.

These valves are widely used in hydraulic systems, pneumatic systems, air conditioning, and various other industrial applications—anywhere that controlling both the flow rate and flow direction is essential for safe and efficient operation.

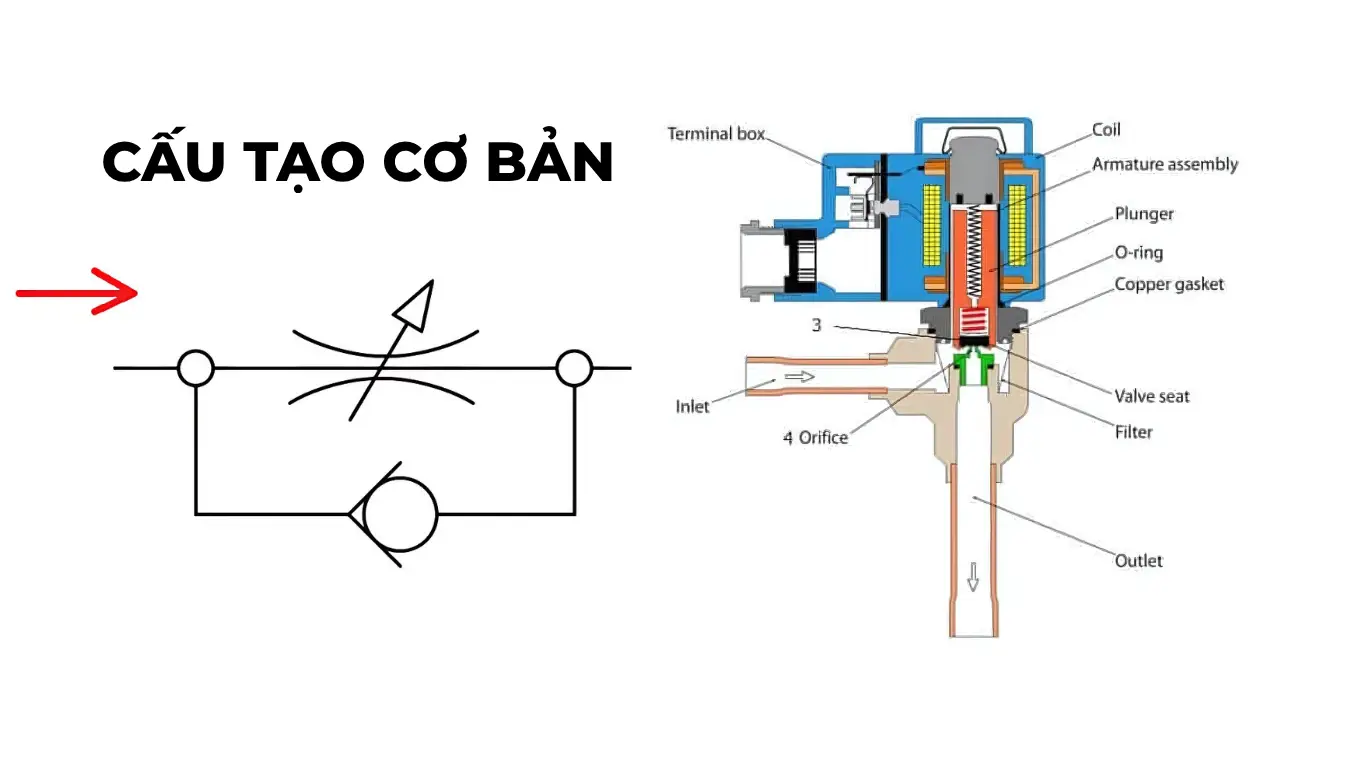

Structure of a throttle check valve

throttle check valve features a compact design while integrating both throttling and one-way (check) functionalities. A typical valve usually consists of the following components:

- Valve body: The outer casing, usually made of stainless steel, carbon steel, or alloys, is designed to withstand high pressure and resist corrosion.

- Needle or valve disc: The core component that regulates flow rate, acting as an adjustable flow restrictor.

- Spring: Automatically closes the valve when the flow stops or reverses direction.

- Adjustment screw or knob: Used to vary the opening of the needle, thereby controlling the flow speed.

- Check valve mechanism: Allows fluid or gas to flow freely in the reverse direction without restriction.

- Sealing gaskets: Ensure leak-proof operation during use.

Depending on the specific type of valve—hydraulic, pneumatic, or electronic—the design may be further optimised with additional features such as filters, sensors, or electrical control units.

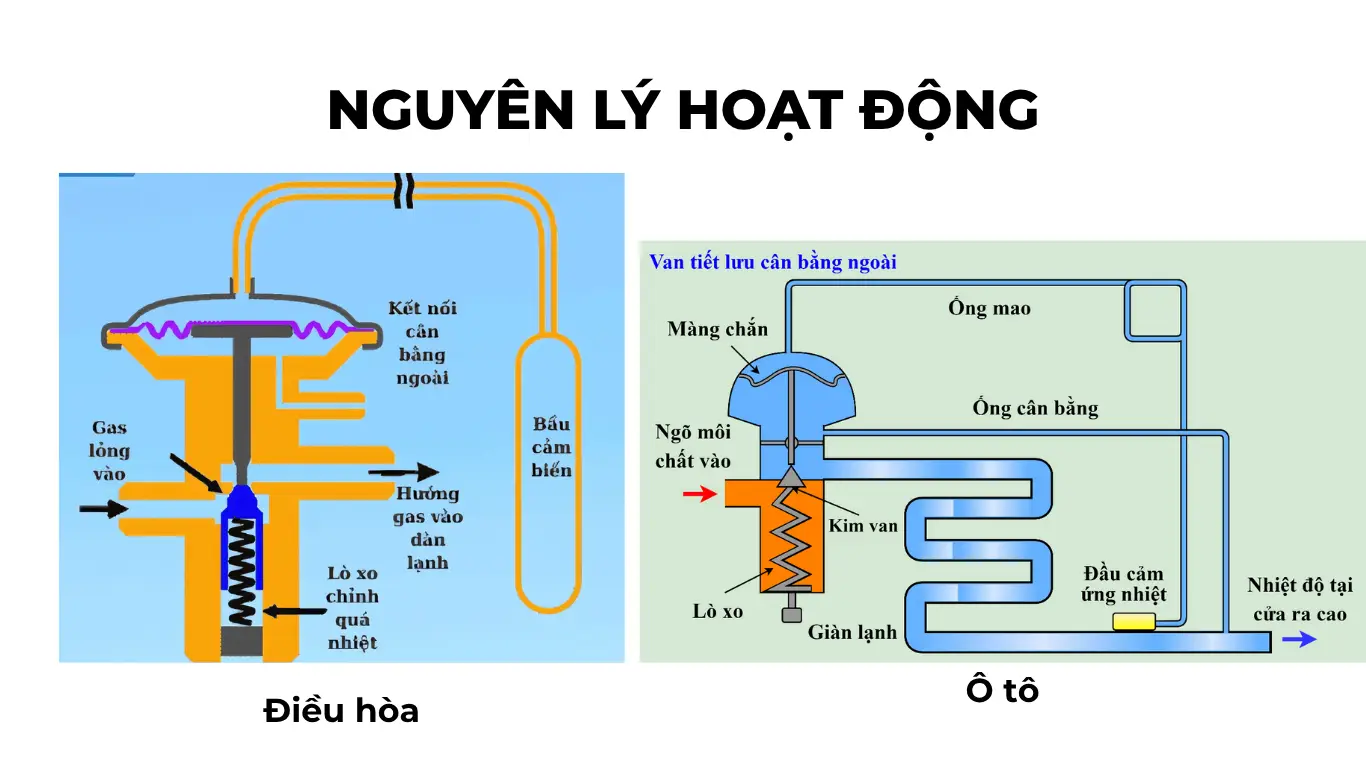

Working Principle

The throttle check valve operates on the principle of controlling flow area in one direction, while allowing unrestricted reverse flow.

- In the throttling (controlled) direction:

When fluid or gas flows in the direction where throttling is applied, it passes through a small orifice inside the valve. A needle or disc partially blocks this flow path. The operator can adjust the screw or knob to increase or decrease the size of the orifice, thereby regulating the flow rate and speed. - In the reverse direction:

The valve bypasses the throttling mechanism and acts like a check valve, allowing fluid or gas to flow freely without resistance.

Thanks to this dual-function mechanism, the valve does both:

- Controls the speed of fluid entering a system (e.g., adjusting the extension/retraction speed of a hydraulic cylinder),

- And ensures that when the flow reverses, the system doesn’t become blocked or damaged.

Types of throttle check valve

Today’s market offers a wide variety of throttle check valves, differing in design, features, and performance. Depending on the application, working medium (fluid or gas), and technical requirements, these valves can be categorised into the following main groups:

Classification Based on Flow Regime

Laminar Flow Valves:

- These valves are designed for smooth, stable, and linear flow. They are ideal for applications requiring precise speed control, such as automated machinery, robotics, or force control systems. However, laminar flow valves tend to be sensitive to temperature changes and fluid viscosity.

Turbulent Flow Valves:

- These valves allow for stronger, more stable flow that is less affected by temperature or fluid properties. Turbulent flow valves are suitable for industrial systems operating under harsh conditions where consistent performance over time is critical.

Classification Based on Adjustability

Non-Adjustable Valves:

- These valves have a fixed flow cross-section predetermined by the manufacturer. Their advantages include simplicity, low cost, and minimal maintenance requirements. However, they lack flexibility in adjusting flow rates.

Adjustable Valves:

- These valves feature an adjustment screw or knob, allowing users to easily control the flow rate in real-time. They are the most commonly used type in systems requiring variable flow speeds, such as controlling cylinders, hydraulic motors, conveyors, and more.

Classification Based on Medium and Control Method

Hydraulic Throttle Valves:

- Designed specifically for systems using hydraulic oil or water. These valves offer high durability and can withstand high pressure, making them common in presses, lifting machines, and industrial robots.

Pneumatic Throttle Valves:

- Used in systems powered by compressed air, such as pneumatic cylinders or automation equipment. These valves are typically lightweight, provide quick response, and operate under lower pressure compared to hydraulic valves.

Electronic Throttle Valves (Servo Control):

- These advanced valves are controlled electronically via signals from sensors or central controllers. They are employed in modern automated systems requiring high precision, remote adjustment, or integration with PLCs (Programmable Logic Controllers).

Practical Industrial Applications

The one-way throttle valve is often likened to an “intelligent gatekeeper” in hydraulic, pneumatic, and air conditioning systems. Thanks to its ability to both regulate flow speed and prevent backflow, this valve is widely used across various industrial and everyday applications. Here are some typical uses:

- Controlling the speed of hydraulic cylinders in presses, lifts, cranes, and hydraulic forklifts enables precise control of lifting and lowering speeds.

- Installed at the inlet or outlet of pneumatic cylinders to reduce compressed air consumption and protect equipment from damage caused by sudden pressure changes.

- Regulating the flow of refrigerant gas entering the evaporator coil, ensuring proper pressure and temperature changes for efficient cooling while preventing reverse gas flow that could cause pressure loss or compressor damage.

- Stabilising CNC machine tables and milling machines during emergency stops.

- Controlling the rotational speed of hydraulic motors.

- Managing speed and force in precise movements of industrial robots.

- Adjusting the flow rate of raw materials in factories processing food, pharmaceuticals, cement, wood, aluminium, glass, and more.

Advantages and Disadvantages of One-Way Throttle Valves

Although compact in size, one-way throttle valves play an indispensable role in many systems. However, like any technical device, they come with certain strengths and limitations that users should understand clearly to select and use them effectively.

Key Advantages of the throttle check valve

- Combines two functions in one device: The valve both regulates flow and prevents backflow, eliminating the need for two separate valves. This reduces the number of components, saves cost and installation space, and minimises potential leak points.

- Accurate flow control: With adjustable valves, you can flexibly regulate the flow rate according to actual needs—extremely useful in hydraulic, pneumatic systems, or machine tools.

- Compact design and easy installation: These valves are typically designed with common threaded connections, compact size, and easy integration into piping systems.

- Increased system stability and safety: Controlling flow and preventing reverse flow help the system operate smoothly, reduce jerking, and avoid dangerous water hammer or pressure shocks.

- High cost efficiency: Compared to more complex flow control devices, one-way throttle valves offer a low investment cost while still providing essential functions for the system.

Important Disadvantages to Note

- Not suitable for high flow systems: Due to design limitations, these valves typically perform well only with low to medium flow rates. For high-capacity systems, alternative solutions should be considered.

- Cannot replace shut-off valves: This valve cannot completely close the flow and may still allow slight leakage—especially after prolonged use.

- Prone to clogging without a filter: Because of the small throttling gaps, the valve can easily become blocked by dirt, rust, or small particles in the fluid. Therefore, the system should include a Y-strainer for protection.

- Durability issues with frequent adjustments: Frequent turning of the adjustment screw may wear out the threads or loosen the screw, leading to premature failure.

- Requires correct installation direction: Installing the valve opposite to the flow direction indicated by the arrow will cause malfunction, potential system damage, or safety hazards.

Installation and Safe Operation Guide

To ensure the device operates efficiently, prolong the valve’s lifespan, and guarantee overall system safety, installation and operation must be performed correctly. Below are the key steps and important notes you should be aware of:

Preparation Before Installation

- Clean the piping system: Before installing the valve, flush the pipes thoroughly to remove dirt, rust, or leftover welding debris. Small particles can clog the valve needle or cause leaks during operation.

- Inspect the valve before installation: Make sure the valve is not dented, has no damaged threads, blockages, or signs of wear. For adjustable valves, test-turn the adjustment screw to ensure smooth operation.

- Measure and verify connection sizes: Confirm the valve’s thread type (or flange) matches the piping system to avoid leaks or improper fitting.

- Use appropriate sealing tape or sealant: For threaded valves, wrap Teflon tape evenly along the threads to ensure a tight seal. Avoid wrapping too thickly, which can cause thread stripping or misalignment.

Proper Installation Direction and Technique

Install the valve according to the arrow direction

- There is always an arrow on the valve body indicating the flow direction. Install the valve so that the flow in the system matches this arrow. Installing it backwards will cause the valve to malfunction or even damage the system.

Align straight and tighten properly

- When installing threaded connections, align the valve and pipe axes correctly to avoid thread misalignment. Use a wrench to tighten firmly but avoid over-tightening, which may crack the valve body.

Place the valve correctly in the system

Depending on the application, valves are usually installed:

- On the flow control branch of cylinders (hydraulic or pneumatic)

- Before the evaporator coil (air conditioning)

- After the pump, on the oil return line or supply line

How to Operate a One-Way Throttle Valve

Adjust the flow gradually

If using an adjustable valve, turn the screw or knob slowly. Generally:

- Turn clockwise → reduce the opening, decrease flow rate

- Turn counterclockwise → increase the opening, increase flow rate

Test operation before full useAfter installation, run a low-pressure test to check:

- Whether the valve leaks

- Whether the valve mechanism operates smoothly

- Whether the flow rate responds to adjustments

Lock the adjustment position

- Some valves have a locking nut on the knob—tighten it after adjusting to prevent unintended changes caused by vibration.

What Not to Do

- Do not use a one-way throttle valve to completely shut off flow (it is not a shut-off valve).

- Avoid turning the adjustment knob excessively or continuously, as this can wear out the threads and strip the screw.

- Do not install the valve without thoroughly checking the cleanliness of the piping.

- Never install the valve opposite to the flow direction indicated by the arrow—this can cause serious system malfunctions, especially in pneumatic and hydraulic systems.

Conclusion

The throttle check valve is a compact yet brilliant solution for controlling flow rates and protecting systems from backflow. With its dual-function integrated design, this device helps optimise performance, simplify systems, and reduce investment costs across various industries—from hydraulics and pneumatics to air conditioning and machine tools.

However, to maximise effectiveness, users need to select the right valve type based on the medium and flow rate, install it correctly according to flow direction, operate it properly, and perform regular maintenance. When applied with proper technical standards, the one-way throttle valve not only ensures smooth system operation but also extends the overall lifespan of the equipment.

If you are looking to purchase high-quality one-way throttle valves or need expert advice on industrial valve solutions, contact Bao Tin Steel at hotline 0932 059 176 for the best support and discover products that perfectly fit your system.

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ