When the pump is turned off and you hear a loud “pop” in the pipeline, the cause is very likely due to a missing or incorrectly installed check valve on the water pump. Small as it may seem, the check valve is the key component that protects the entire water pumping system from dangerous issues such as backflow, pressure loss, water hammer, or contamination of the clean water source.

According to technical experts, a check valve not only prevents reverse water flow when the pump stops operating but also helps maintain stable outlet pressure and keeps water inside the pump chamber—eliminating the need for priming every time the pump is started. This is especially important for systems where the pump is positioned higher than the water source—such as deep wells, reservoirs, or underground tanks—where a check valve is practically mandatory.

However, in practice, many people still choose check valves based on guesswork—for example, simply matching a DN50 pipe with a DN50 valve—without considering factors like flow rate, pressure, material, or installation orientation. As a result, the valve may make clicking noises, vibrate, wear out prematurely, or even cause pump failures.

In this article, Bao Tin Steel will walk you through:

- What a water pump check valve is.

- The different types of check valves and which systems each type is best suited for.

- How to select the right check valve based on flow rate, pressure, and operating environment.

- And finally, the proper installation methods to ensure stable and long-lasting operation.

What Is a Water Pump Check Valve?

A water pump check valve—also known as a non-return valve or backflow prevention valve—is a mechanical device that allows water to flow in only one direction and automatically closes when the flow reverses.

Unlike other types of valves that require manual or automated operation, a check valve functions entirely automatically based on the pressure differential within the pipeline.

Main Functions of a Check Valve in a Pumping System

- Prevents backflow: When the pump stops running, water in the pipeline may flow backwards, potentially damaging the impeller or carrying debris into the pump. The check valve prevents this from happening.

- Maintains pressure and keeps the pump primed: It helps the pump remain ready for operation without the need for re-priming each time, which is especially useful for systems that draw water from deep wells or underground tanks.

- Protects the system from contamination: Prevents dirty water, chemicals, or wastewater from flowing back into the clean water supply.

- Reduces the risk of water hammer: Certain quick-closing check valves (such as spring-loaded types) help minimise the “water hammer” effect—a sudden pressure surge that can cause loud noises and damage the pipeline.

Installation Position in the System

Check valves are typically installed immediately after the pump, or at the bottom of the suction line in the case of a foot valve (also known as a suction strainer or pump strainer).

Their purpose is to prevent reverse flow when the pump stops and to ensure that water always flows in the intended direction within the system.

Common Types of Check Valves for Water Pumps

Depending on their design, operating environment, and technical requirements, there are several types of check valves used in water pump systems.

Below are the most commonly used ones:

Swing Check Valve for Water Pumps

Construction:

A hinged disc or flap is attached to the valve body, which opens when water flows in the forward direction and closes when the flow stops or reverses.

Advantages:

- Simple design, easy to maintain.

- Cost-effective.

- Minimal flow resistance.

Disadvantages:

- Closes slowly → can cause water hammer if the system shuts down suddenly.

- Not suitable for low-flow or low-pressure applications.

Applications:

Used in residential water supply systems, wastewater treatment, and medium to large-scale industrial pumping systems.

Some Suitable Swing Check Valve Models for Water Pumps:

=> Learn more: What is a check valve? Structure, principle and installation

Spring-Loaded Check Valve for Water Pumps (Silent Check Valve)

Construction:

Equipped with a spring that pushes the valve disc to the closed position when pressure drops.

Advantages:

- Closes quickly → reduces the risk of water hammer.

- Quiet operation with minimal noise.

- Suitable for systems with fluctuating pressure.

Disadvantages:

- May cause pressure loss due to spring resistance.

- Not suitable for water containing sediment or solid particles.

Applications:

Used in fire protection systems (FPRS), HVAC, clean water supply, and situations requiring precise flow control.

Some Suitable Spring-Loaded Check Valve Models for Water Pumps:

=> Learn more: What is a Spring Check Valve? Classification, Applications and How to Choose

Ball Check Valve for water pump

Construction:

Uses a ball to open and close the water flow based on pressure differential.

Advantages:

- Self-cleaning, capable of handling flows with light sediment or sludge.

- Operates reliably in both horizontal and vertical orientations.

Disadvantages:

- Requires cushioning pads to prevent harsh closing impacts.

- Should not be installed upside down or against the flow direction.

Applications:

Suitable for wastewater treatment systems, flows containing sediment, sludge pumping, and chemical pumping.

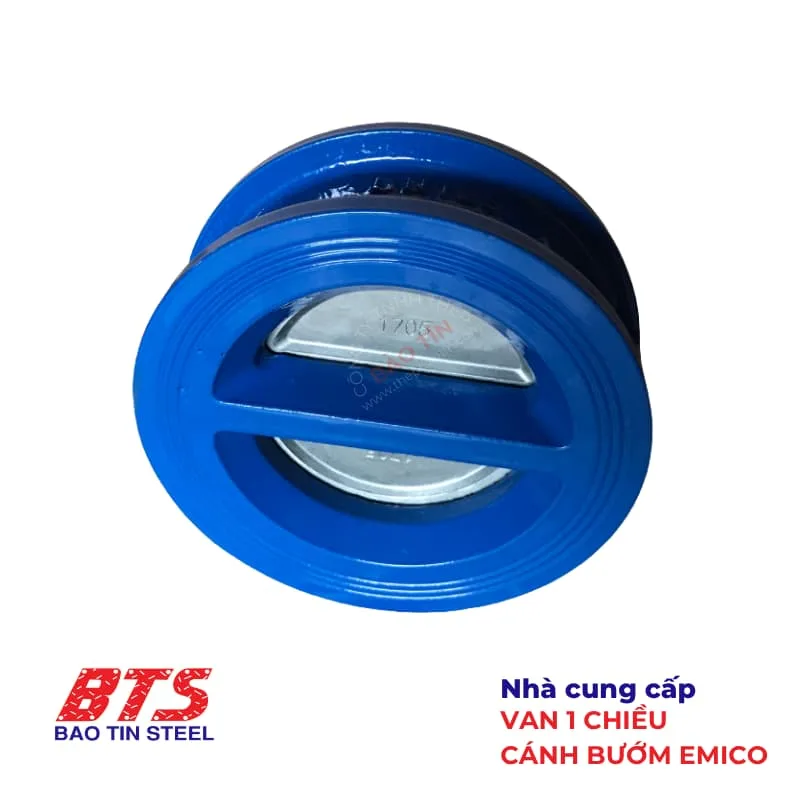

Double Disc Check Valve (also called Dual Plate Check Valve)

Construction:

Consists of two semi-circular discs that open when water flows and close quickly thanks to the spring force.

Advantages:

- Compact, lightweight, and easy to install between flanges.

- Fast closing action reduces the risk of water hammer.

Disadvantages:

-

Not suitable for liquids containing impurities or solid particles.

Applications:

Used in clean water pumping systems, fire protection systems (FPRS), and confined pump rooms.

Some Suitable Butterfly Check Valve Models for Water Pumps:

Foot Valve

Construction:

A check valve is installed at the bottom of the suction pipe, equipped with a strainer to prevent debris from entering.

Advantages:

- Maintains the pump’s prime (keeps water in the pump).

- Prevents debris from entering the pump, extending its lifespan.

Disadvantages:

-

Prone to clogging if not cleaned regularly.

Applications:

Used in boreholes, reservoirs, ponds, and for pumping from sources located below the pump level.

Some Suitable Foot Valve Models for Water Pumps:

Criteria for Choosing an Effective Check Valve for Water Pumps

When selecting a valve, you shouldn’t rely solely on the pipe size. It’s essential to carefully consider other factors such as operating pressure, flow rate, and more. Below are the important criteria you need to take into account:

Operating Pressure & Cracking Pressure

- Operating Pressure: This is the regular pressure level within the system. The valve must withstand this pressure reliably over long periods.

- Cracking Pressure: The minimum pressure required to start opening the valve. If the cracking pressure is too high, a weak pump may not generate enough force to open the valve; if too low, the valve may slam shut, causing water hammer.

Note: For systems with fluctuating pressure, it is advisable to choose spring-loaded or dual-plate check valves with spring assistance to ensure quick closing and minimise flow fluctuations.

Actual Flow Rate

- The valve must operate stably within the flow rate generated by the pumping system.

- If the valve is oversized compared to the actual flow, the valve disc will continuously oscillate—a phenomenon called chatter. This is highly detrimental, causing rapid wear of valve components, unwanted vibrations in the system, and significantly reducing the overall valve lifespan. Over time, this can lead to failure and operational downtime.

Valve Material Suitable for the Working Environment

| Liquid Environment | Recommended Valve Materials |

|---|---|

| Clean water, cold water | Cast iron, brass, engineering plastics |

| Hot water, mild chemicals | Stainless steel 304/316 |

| Water with sediment, light wastewater | Steel ball with rubber coating, cast iron disc with EPDM lining |

| Deep wells, pond water | Foot valve with stainless steel strainer |

Connection Types & Installation Space

- Threaded Connection: Suitable for residential systems and small-capacity setups.

- Flanged Connection: Used in industrial systems with large pipes; allows easy disassembly and maintenance.

- Wafer Type (sandwiched between two flanges): Compact and space-saving but requires precise installation.

If installation space is limited, it’s advisable to prioritise butterfly check valves and foot valves with integrated strainers. These valves share a compact design, making them easy to install even in the tightest spaces while maintaining good operational performance.

Installation Orientation & Flow Direction

The orientation of the system—horizontal or vertical—affects the type of valve you should use:

- Horizontal installation: Most valve types can be used (swing, spring-loaded, ball, etc.).

- Vertical installation (flow going upwards): It’s recommended to choose spring-loaded valves or swing valves that are gravity-assisted.

Pay attention to the arrow mark on the valve body to ensure it matches the flow direction.

Valve Sensitivity & Water Hammer Resistance

For systems with a high risk of water hammer, it’s recommended to prioritise valves that:

- Close quickly (spring-loaded valves)

- Have anti-slam designs (silent check valves, axial flow valves)

Swing check valves without springs tend to close slowly, which can cause loud “bang” noises if the water flow suddenly reverses.

Maintenance Requirements & Durability

For critical or hard-to-access systems, you should choose valves that have:

- Durable, corrosion-resistant materials.

- Easy disassembly for cleaning and quick replacement.

Don’t overlook the lifecycle cost, which includes more than just the initial purchase price.

How to Properly Install a Check Valve for Water Pumps

Besides selecting the right type of check valve suitable for your system and pump, the installation process is equally important. Proper installation ensures optimal performance and the overall longevity of the system.

Here is a detailed guide along with important notes you should keep in mind:

Valve Installation Location in the System

Standard Location:

Install the valve immediately after the pump discharge. This position prevents backflow when the pump stops and reduces hydraulic pressure on the impeller.

Ideal Pipe Lengths:

- Upstream pipe (before the valve) should be at least 5 times the pipe diameter (5D).

- The downstream pipe (after the valve) should be about 5–10D long.

Purpose:

To minimise turbulence, stabilise flow before entering the valve, and avoid chatter, water hammer, or premature wear of the valve disc.

Flow Direction and Valve Orientation

- Always check the arrow indicating the flow direction on the valve body — it must match the water flow direction from the pump.

- Incorrect installation direction can cause the valve to remain closed, resulting in blockage or even damaging the entire system.

Special Notes for Different Valve Types

- For swing check valves or foot valves, if installed vertically, the flow must go from bottom to top.

- For ball check valves or butterfly check valves, they can be installed horizontally or vertically — but always confirm with the manufacturer’s specifications for each specific model.

Flow Direction and Valve Orientation

| Connection Type | Installation Guidelines |

|---|---|

| Flanged | Use sealing gaskets (EPDM, PTFE, etc.) between flanges. Tighten bolts in a star pattern (5–6 points) evenly. Do not overtighten to avoid valve deformation. |

| Threaded | Wrap with PTFE tape or apply suitable thread sealant. Do not overtighten to prevent cracking the valve body. |

| Wafer (Sandwiched between flanges) | Precisely align the valve and flange centres. Use bolts to fasten through both flanges. Carefully check that the valve disc is not stuck when opening or closing. |

Specific Installation Instructions by Valve Type

Foot Valve:

- Install at the bottom of the well or suction inlet, with the strainer facing downward.

- Must be installed vertically and positioned at least 30–50 cm above the ground to avoid sucking in sand and debris.

Spring Check Valve (Silent/Spring Check):

- It can be installed horizontally or vertically as long as the flow direction is correct.

- Particularly suitable for systems that require water hammer prevention.

Swing Check Valve:

- It can be installed horizontally or vertically (with upward flow).

- Avoid installing in low-pressure areas because slow closing may cause water hammer.

Other Important Technical Notes

- Do not install the valve immediately after elbows, tees, or the pump, as these locations have strong turbulence, which can cause impact and rapid wear.

- Do not weld or cut directly on the valve to avoid deforming the valve body or damaging the disc.

- Properly support the piping to avoid hanging forces or tension that could misalign the valve shaft.

- Ensure sufficient working space around the valve for easy maintenance, inspection, and future replacement.

Maintenance and Regular Cleaning Guide for Check Valves in Water Pump Systems

Although check valves operate fully automatically and are less prone to failure compared to control valves, a lack of regular maintenance can lead to issues such as valve sticking, leakage, incomplete closure, backflow, or reduced flow rate.

Proper maintenance helps to:

- Extend the lifespan of both the valve and the pump.

- Ensure continuous and stable system operation.

- Avoid unexpected replacement and repair costs.

Regular Inspection Schedule

| Maintenance Item | Recommended Frequency |

|---|---|

| Visual inspection | Monthly |

| Leak inspection | Every 2–3 months or after a sudden pump shutdown |

| Internal valve cleaning | Every 6 months or when sediment is noticed |

| Replace gaskets, springs | Annually (or as per manufacturer’s recommendation) |

| Check flow rate & pressure | According to the pump maintenance schedule |

Regular Cleaning Procedure for Check Valves in Water Pump Systems

Step 1: Shut down the system and release all pressure before removing the valve.

Step 2: Remove the valve from the system, taking care not to scratch the flange or threads.

Step 3: Clean the inside parts using a soft brush, clean water, or a neutral cleaning solution to remove deposits, algae, and light rust.

Step 4: Inspect all components: valve disc, shaft, ball, spring, gasket, etc.

Step 5: Replace any parts showing signs of:

- Hardened or cracked gaskets

- Scratched or unevenly worn balls

- Weak or broken springs

Step 6: Reinstall the valve and test it with clean water at moderate pressure to ensure smooth opening and closing.

Lubrication of Moving Parts (If Applicable)

Some types of valves, such as spring check valves or disc valves with rotating shafts, require light lubrication on their moving joints.

Use water industry-approved lubricants that are non-toxic and do not affect water quality.

Tight Shutoff Test

After cleaning and reassembly, you can check the valve’s sealing performance by:

- Filling the valve with water and drying the outside surface.

- Place a dry paper or cloth under the valve body.

- If you see any water leakage → inspect and replace gaskets or discs, or tighten the connections.

This simple method is highly effective for early detection of valve sealing issues.

Periodic Replacement of Check Valves for Water Pumps (Based on Usage Cycle)

- Some types of valves (such as plastic valves or residential swing check valves) have a limited lifespan and should be replaced every 3–5 years, depending on the intensity of use.

- For systems operating continuously under high pressure, it is advisable to keep spare valves ready for replacement when signs of damage appear.

Conclusion

Check valves for water pumps may be a small component in the entire system, but they play a crucial role in:

- Preventing backflow, protecting the pump from damage.

- Maintaining pressure and keeping the pump primed allows for quick system startup.

- Reducing water hammer, minimising vibration, noise, and leakage.

- Extending equipment lifespan, saving on operating and maintenance costs.

However, to maximise the effectiveness of check valves, you need to:

- Choose the right type of valve based on flow rate, pressure, material, and installation type.

- Install correctly, ensuring proper flow direction, tight sealing, and system stability.

- Perform regular maintenance to detect early issues like leakage, stuck valves, or broken springs.

Unsure which valve to choose?

Let bao Tin Steel assist you!

With experience supplying thousands of genuine industrial valves for large and small projects nationwide, we guarantee:

- Accurate technical consultation tailored to your system and budget.

- Full CO-CQ certification, clear origin, and transparent warranty.

- Competitive prices, fast delivery, and on-site support.

Contact us now for consultation and the best quote on check valves:

Hotline: 0932 059 176

Email: bts@thepbaotin.com

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ