In industrial pneumatic systems, there’s a small yet critically important component — the pneumatic check valve. Often “hidden” among numerous other devices such as compressors, cylinders, and control valves, the check valve plays an essential role: it allows compressed air to flow in only one direction while preventing reverse flow, which could cause pressure drops, equipment damage, or system disruptions.

With advantages like automatic operation, no need for electricity, and easy installation and maintenance, pneumatic check valves are widely used across various industries such as manufacturing, assembly, food processing, healthcare, and more.

If you’re looking to understand this type of valve from A to Z — from its structure, working principle, and types to real-world applications — then this article will serve as your comprehensive, easy-to-understand, and practical guide!

What is a Pneumatic Check Valve? Why Is It Important?

A pneumatic check valve (also known as a non-return valve) is a mechanical device that allows compressed air to flow in only one direction, while automatically blocking any reverse flow. When the inlet pressure is higher than the outlet pressure, the valve opens to let air pass through. Conversely, if the outlet pressure becomes higher or there is a reversal in flow direction, the valve closes immediately to stop the backflow.

Why is this valve so important?

In pneumatic systems, reverse airflow can cause numerous issues, such as sudden pressure drops, damage to air compressors, malfunctioning of control equipment, or even air leakage into the environment. The pneumatic check valve acts as a protective barrier, ensuring stable pressure, safeguarding the entire system, and helping to conserve energy by preventing re-compression of already-used air.

One key advantage is that the valve operates purely based on pressure differences — it requires no electricity, no programming, making it simple, durable, and low-maintenance. This makes it an ideal choice for automated production lines and various industrial applications.

Structure and Working Principle of a Pneumatic Check Valve

Basic Structure of a Pneumatic Check Valve

A pneumatic check valve typically has a simple yet highly effective design, made up of the following main components:

- Valve Body: The outer casing, usually made of brass, stainless steel, or engineering plastic. It shapes the airflow path and protects the internal components.

- Flow Blocking Element: This can be a ball, poppet, or rubber diaphragm, and it’s the core part that opens or closes to control the airflow direction.

- Spring (if present):Provides a return force to keep the blocking element in the closed position when there isn’t enough inlet pressure.

- Seal (O-ring): Ensures a tight closure, preventing air leakage and maintaining system efficiency.

Depending on the application, the valve may come with threaded connections, quick-connect fittings, or be integrated into other pneumatic components.

Working Principle of a Pneumatic Check Valve

A pneumatic check valve operates based on the pressure difference between the inlet and the outlet:

- When the inlet pressure is higher than the outlet pressure and exceeds a specific threshold known as the cracking pressure, the blocking element (ball, poppet, or diaphragm) is pushed open, allowing compressed air to flow through the valve in the intended direction.

- When the inlet pressure drops or the outlet pressure rises (causing a potential reverse flow), the spring (or gravity, depending on the design) forces the blocking element back to its closed position. This action seals off the valve, preventing any reverse airflow from re-entering the system.

This mechanism is completely automatic — it requires no electricity, sensors, or external control systems, making it highly convenient, energy-efficient, and safe for industrial environments.

Common Types of Pneumatic Check Valves

Although all pneumatic check valves operate on the same one-way flow principle, they come in various designs to suit specific applications and system requirements. Below are the most commonly used types today:

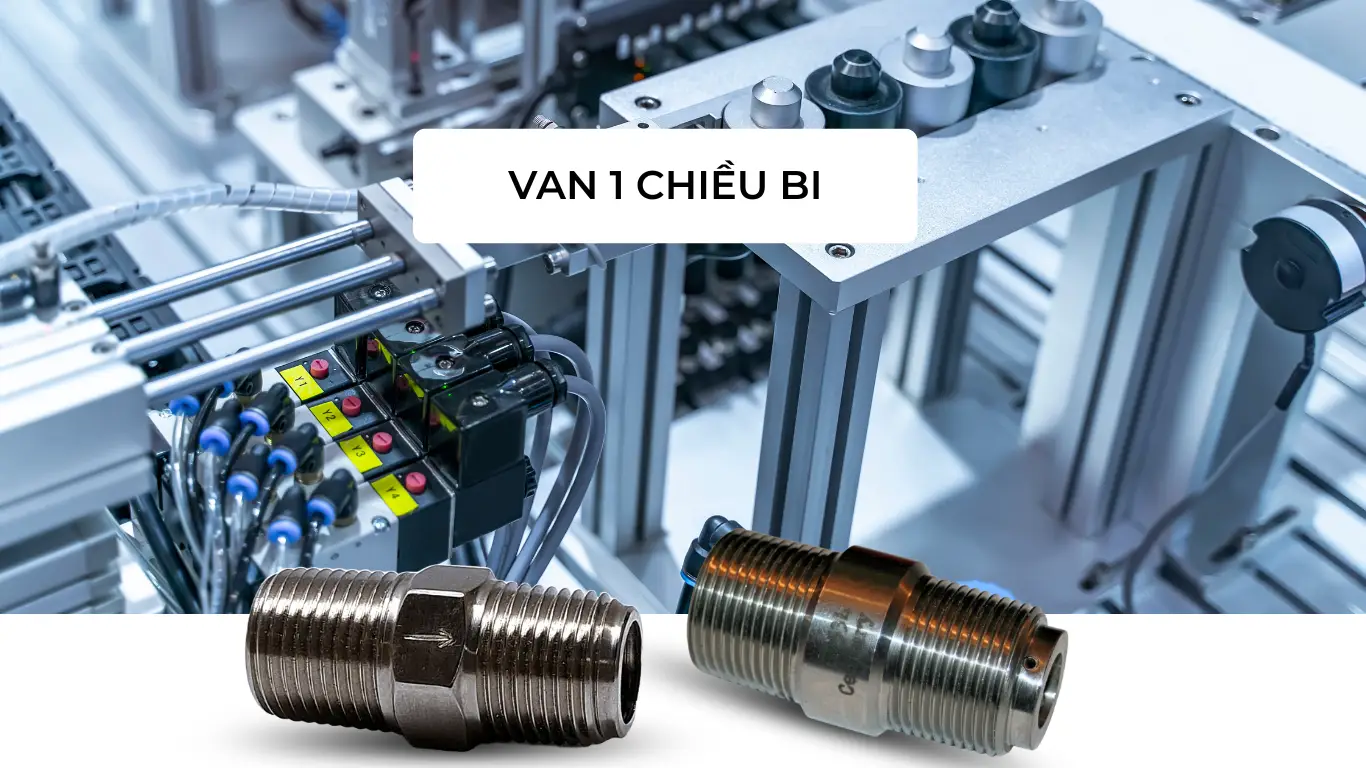

Ball Check Valve

This type of valve features a round ball housed inside the valve body. When the inlet pressure is high enough, the ball is pushed away from its seat, allowing compressed air to flow through. Once the airflow stops or reverses direction, the ball automatically returns to its original position, sealing off the passage and preventing backflow.

Advantages:

- Excellent air sealing performance

- Simple construction

- Low risk of mechanical failure

Typical Applications:

- Pneumatic systems with stable flow rates

- Systems with minimal vibration or pulsation

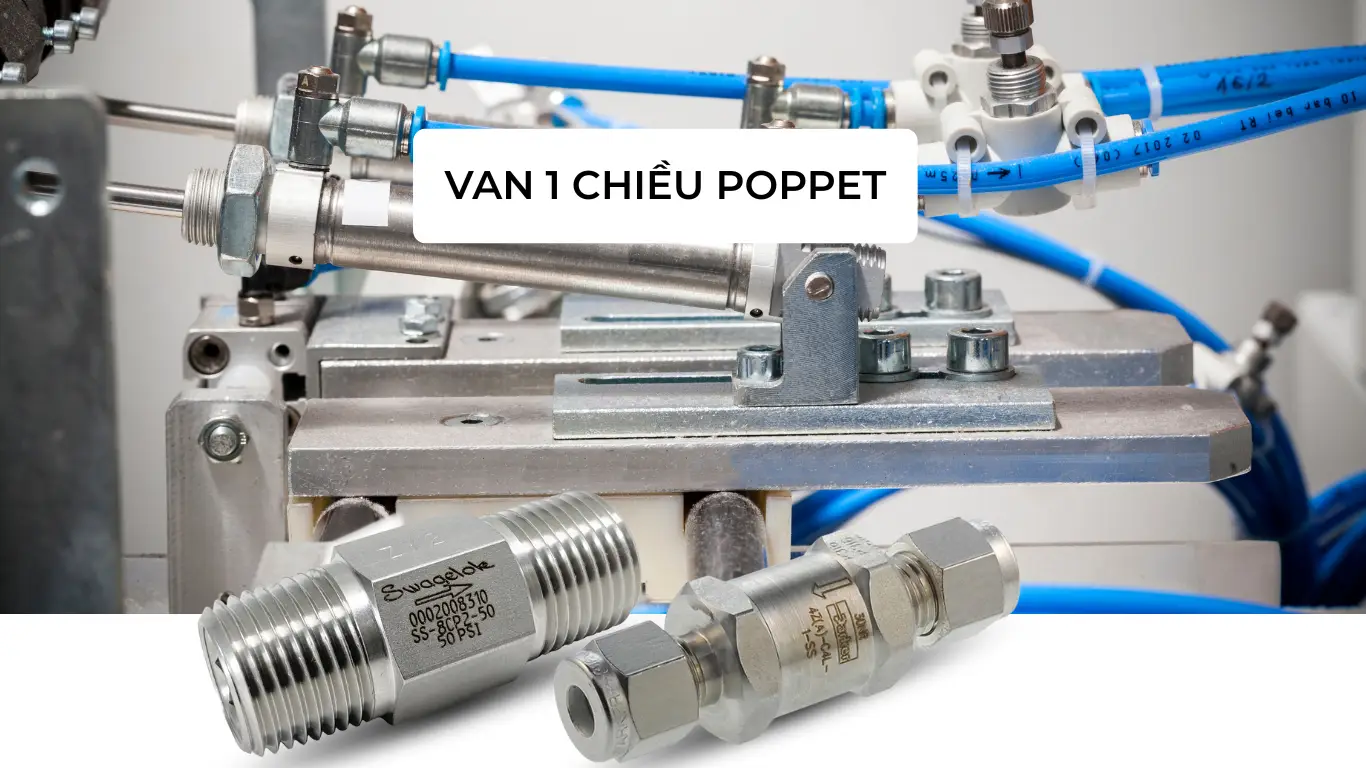

Poppet Check Valve

This type of valve uses a small disc or plunger (poppet) attached to a spring. When air flows in the correct direction, the poppet is pushed open. If there is reverse flow or a drop in pressure, the spring pushes the poppet closed, sealing the valve.

Advantages:

- Quick response

- Excellent airtight sealing

- Capable of operating under high pressure

Applications:

- Industrial pneumatic systems

- Pneumatic cylinders

- Actuators and other pneumatic drive mechanisms

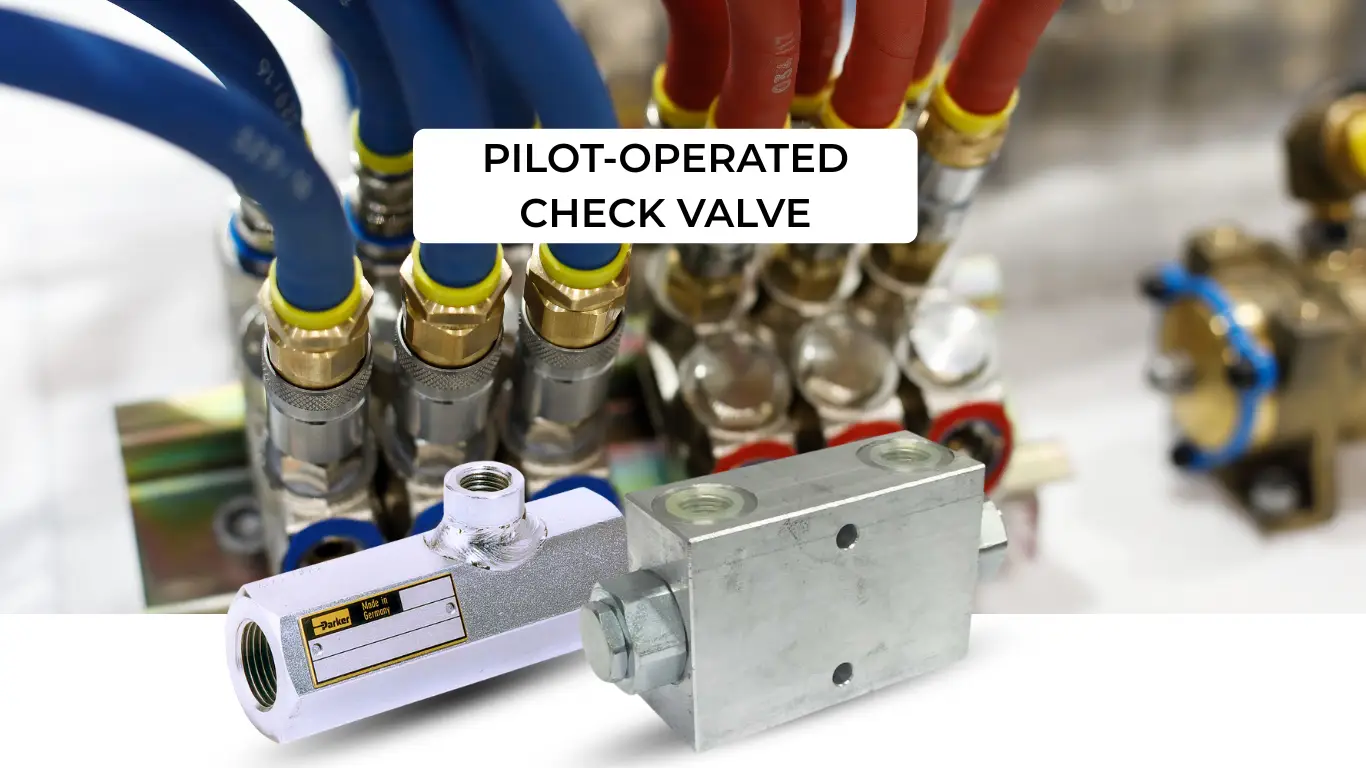

Pilot-Operated Check Valve

Unlike the previous two types, this valve features an additional pilot port to receive a control air signal. The valve only opens when both the inlet pressure and a signal from the control port are present.

Advantages:

-

Allows more flexible control of airflow.

Applications:

- Holding cylinders in position when air supply is lost

- Emergency stops

- Logic-based pneumatic control systems

Swing, Lift, and Diaphragm Check Valves (Less Common in Pneumatics)

Some specialized systems may use the following types of check valves:

- Swing Check Valve:Features a hinged flap that swings open and closed with the flow.

- Lift Check Valve:Uses a piston or disc that lifts up and down following the airflow.

- Diaphragm Check Valve:Employs a rubber diaphragm that opens and closes in response to pressure changes.

These types are more commonly used in water or steam systems and are rarely found in modern pneumatic systems.

Applications of Pneumatic Check Valves in Industrial Systems

Pneumatic check valves are not just auxiliary components; they play a crucial role in many real-world operational scenarios. Below are some of the most common industrial applications:

Maintaining Pressure and Protecting Equipment

In systems with an air compressor and an air receiver tank, a check valve is installed between the compressor and the tank. When the compressor stops operating, the valve prevents air from flowing back from the tank to the compressor, which helps to:

- Maintain stable pressure inside the tank.

- Prevent the compressor from restarting unnecessarily, saving electricity and reducing equipment wear.

Airflow Control – Bypass Applications

Devices such as solenoid valves, sensors, and air filters can be easily affected by reverse airflow. Installing a check valve right before these sensitive components helps to:

- Protect equipment from pressure shocks or leaks.

- Ensure that the airflow direction is always correct within the control circuit.

Controlling Pneumatic Cylinder Speed

In pneumatic cylinder control circuits, check valves are often combined with flow control valves (throttle valves) to regulate the opening and closing speed in each direction:

- Fast direction: Air flows freely through the check valve without restriction.

- Slow direction: Air passes through an adjustable flow control valve, reducing speed.

This is a simple and effective solution for precise motion control.

Integration in Quick Couplers – Preserving Pressure

Some types of pneumatic quick couplers have built-in check valves, which allow:

- Disconnecting equipment without air leakage.

- Safe and convenient tool changes for pneumatic devices such as air guns, grinders, and more.

Applications of Pneumatic Check Valves in Logic Functions and Safety

- OR Logic: Allows selecting the higher pressure signal from two sources.

- Emergency Stop – Cylinder Holding: Uses pilot-operated check valves to hold cylinders in position when the air supply is lost.

- Preventing Hose Whip: Stops sudden hose movements if a pipe disconnects, reducing the risk of accidents.

Clearly, pneumatic check valves are found in nearly all critical sections of industrial pneumatic systems — from air supply and actuation to logic control. Though small in size, their impact on system performance and safety is significant.

Advantages and Disadvantages of Pneumatic Check Valves

Like any industrial device, pneumatic check valves have their strengths and limitations.

Key Advantages:

| Advantages | Description |

|---|---|

| Effective prevention of backflow | Protects equipment, maintains stable pressure, and prevents leakage. |

| Automatic operation | No electricity or programming needed — the valve opens/closes based on system pressure. |

| Simple construction, low failure rate | Easy to install, replace, and maintain with low costs. |

| Extends compressor and cylinder lifespan | Reduces repeated charging/discharging and pressure shocks. |

| Versatile applications | Suitable for small pneumatic systems to automated industrial production lines. |

| Energy saving | Prevents air loss and reduces compressor duty cycles. |

Some Limitations:

| Disadvantages | Description |

|---|---|

| Not suitable for highly fluctuating airflow | May cause “valve chatter,” which affects durability. |

| It can produce noise when closing quickly | Especially in systems with high pressure or high airflow speed. |

| Susceptible to dust and moisture | If the compressed air is not properly filtered, the valve can stick or leak. |

| Cannot control the opening/closing speed | Unlike control valves, check valves do not regulate flow rate. |

| Performance depends on compressed air quality | Dirty air, lack of lubrication, or moisture can reduce valve lifespan. |

Tips for Choosing the Right Pneumatic Check Valve

When selecting a pneumatic check valve, you should not only consider size or cost but also take into account technical factors and the operating environment. Below are important tips to keep in mind before purchasing or installing:

Determine Operating Pressure and Cracking Pressure

- Every valve has a specified operating pressure limit. You need to check whether the pneumatic system’s pressure matches the valve’s technical specifications.

- It is advisable to choose valves with a low cracking pressure (0.1 – 0.5 bar) to allow airflow to pass easily when opening, preventing unnecessary pressure drops at the inlet.

- However, in environments with vibration or unstable pressure, valves with a higher cracking pressure can help prevent unintended valve opening.

Choose the Right Design and Operating Mechanism

- Ball Check Valve: Suitable for medium flow rates and simple systems.

- Poppet Valve: Ideal for systems requiring quick response and tight sealing.

- Pilot-Operated Check Valve: Perfect for holding cylinders when air supply is lost, emergency stops, and pneumatic logic applications.

If more intelligent control is needed, choose a pilot-operated check valve that can be opened by a pilot signal.

Select Valve Materials Suitable for the Environment

| Material | Characteristics | Suitable Applications |

|---|---|---|

| Brass | Low cost, easy to machine | Standard pneumatic systems |

| Stainless Steel | Corrosion-resistant, durable | Humid environments, corrosive conditions, and food hygiene |

| Engineering Plastic | Lightweight, inexpensive | Low flow rates, not suitable for high temperatures |

Don’t forget to check the sealing material (O-ring): Viton or PTFE should be used if the air contains oil or if operating at high temperatures.

Pay Attention to Connection Size and Installation Type

- Valves can have threaded connections, quick-connect (push-in) fittings, or small flanges.

Make sure the thread size or tubing matches the existing pneumatic piping.

For systems requiring quick replacement, choose valves integrated with quick-connect accessories to save time.

Check Flow Rate and Installation Direction

- Ensure the valve’s airflow capacity matches your usage requirements. Choosing a valve that is too small can cause flow restriction, while a valve that is too large may reduce sealing effectiveness.

Always install the valve according to the arrow marked on the body. Incorrect installation direction will prevent airflow or damage downstream equipment.

Prioritise reputable brands with a clear warranty.

- Choose valves from brands with technical inspection, clear specifications, and transparent origin.

- Genuine valves are a bit more expensive, but operate stably, last a long time, and save on repair costs later.

Maintenance Guide for Pneumatic Check Valves

Although pneumatic check valves have a simple design and stable operation, regular maintenance is necessary to maintain long-term performance and durability. Proper servicing helps prevent air leaks, avoid valve sticking, and minimise system damage.

Here are some basic and easy maintenance steps:

Cleaning the Area Around the Pneumatic Check Valve

- Use a soft cloth to wipe away dust, oil, and grease around the valve.

- If the valve is in a dusty or humid environment, use a small brush to clean crevices.

- Avoid letting dirt accumulate for long periods — contaminants can enter the valve through the airflow and cause sticking.

Check for Air Leaks

- Use soapy water to lightly brush around connection points and the valve body. If bubbles appear, the valve may be leaking or the seals may be worn.

- Tighten connections or replace seals if necessary.

- For specialised systems, use a flow meter to detect small leaks.

Remove and Inspect the Valve Internals (if possible)

Remove the valve from the pneumatic system (after fully releasing the pressure).

Open the valve cover and check the ball, disc, or poppet:

- Are they clean?

- Are there signs of wear, cracks, sticking, or dirt?

Clean them with a specialised cleaning solution or clean pneumatic oil.

Do not use corrosive chemicals or sharp tools to scrape, as this can damage the sealing surfaces.

Light Lubrication (if necessary)

- Use pneumatic-specific lubricant grease (free of clay or metal particles).

- Apply lightly to the poppet shaft or spring to help the valve open and close smoothly and prevent sticking.

Reassemble and Test After Maintenance

- After cleaning and reassembling the valve, supply compressed air and test its operation:

- Does the valve open and close smoothly?

- Are there any air leaks or unusual noises?

- If the valve still sticks or leaks after maintenance, it’s best to replace it to ensure system safety.

Recommended Maintenance Frequency for Pneumatic Check Valves

| Usage Level | Working Environment | Recommended Maintenance Frequency |

|---|---|---|

| Normal | Clean, dry, stable | Every 3 – 6 months |

| Heavy (continuous) | Dusty, humid, high vibration | Every 1 – 2 months |

Important Notes:

- Do not perform maintenance while the system is still pressurised.

- Absolutely avoid using silicone-based lubricants if the pneumatic system requires high cleanliness standards (e.g., food processing, medical industries).

- For valves integrated into quick couplings or special accessories, refer to the manufacturer’s technical instructions before disassembling.

Conclusion

The pneumatic check valve may be a small component within the entire system, but it plays a crucial role in protecting equipment, maintaining stable pressure, and ensuring long-term operational efficiency. Thanks to its simple design, fully automatic operation, and easy integration, this type of valve is widely used in manufacturing, assembly, packaging, food processing, medical, and many other industries.

However, to ensure stable system performance and save on maintenance costs, you need to select the right valve suitable for your specific pressure, flow, material, and application requirements. Don’t compromise by choosing low-quality valves just to save initial costs — the consequences could be system failures, air leaks, pressure loss, and production interruptions.

Are you looking for high-quality, reasonably priced pneumatic check valves readily available in stock?

At Bao TIn Steel, we offer a full range of pneumatic check valves from standard to premium, including:

- Ball valves, disc valves, poppet valves, pilot-operated check valves

- Materials: brass, stainless steel, technical plastics – various connection types

- Genuine imported products with full CO-CQ and detailed technical specifications

Our commitments:

- Genuine products with dedicated technical consultation

- Nationwide delivery with price quotes within 30 minutes

- Attractive discounts for bulk orders

Contact Bao Tin Steel now for advice on the most suitable valves for your system!

Hotline: 0932 059 176

Email: bts@thepbaotin.com

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ