In high-pressure steam systems such as boilers, heating, and steam distribution networks, the steam check valve plays a crucial role in preventing reverse steam flow — a major cause of serious issues like water hammer, condensate accumulation in pipelines, equipment damage, and overall system pressure loss.

The steam check valve operates fully automatically, without requiring electricity or any external control mechanism. When the inlet pressure is sufficient, the valve opens automatically. Conversely, when the steam flow weakens or reverses, the valve closes instantly, effectively protecting pumps, pipelines, and the entire steam circuit.

Although its design is relatively simple, choosing the wrong valve type, material, or installation direction can lead to inefficient operation or even system failure. Therefore, a proper understanding of the structure, working principle, and selection criteria of steam check valves is essential for engineers, contractors, and industrial plant operators.

What is a Steam Check Valve?

A steam check valve is a type of flow control valve specifically designed for steam systems. It allows steam to flow in only one direction and automatically closes when the flow stops or reverses. The primary purpose of this valve is to prevent backflow, which can cause severe damage to equipment, protect boilers, steam traps, and piping systems, and ensure the overall safety and efficiency of the operation.

Unlike check valves used for water or compressed air, steam check valves are built to withstand high pressure and temperature, providing tight sealing and reliable performance in harsh industrial environments. They can operate based on gravity, spring force, or a combination of both, and typically do not require electricity or external control, which makes them ideal for continuous operation systems.

Depending on specific technical requirements—such as installation orientation, operating pressure, or steam purity—users can choose among different designs, including lift check valves, ball check valves, or spring-loaded piston check valves. Despite their variations, all types follow the same fundamental principle: they open when steam flows in the correct direction and close immediately when reverse flow is detected.

Structure and Working Principle of a Steam Check Valve

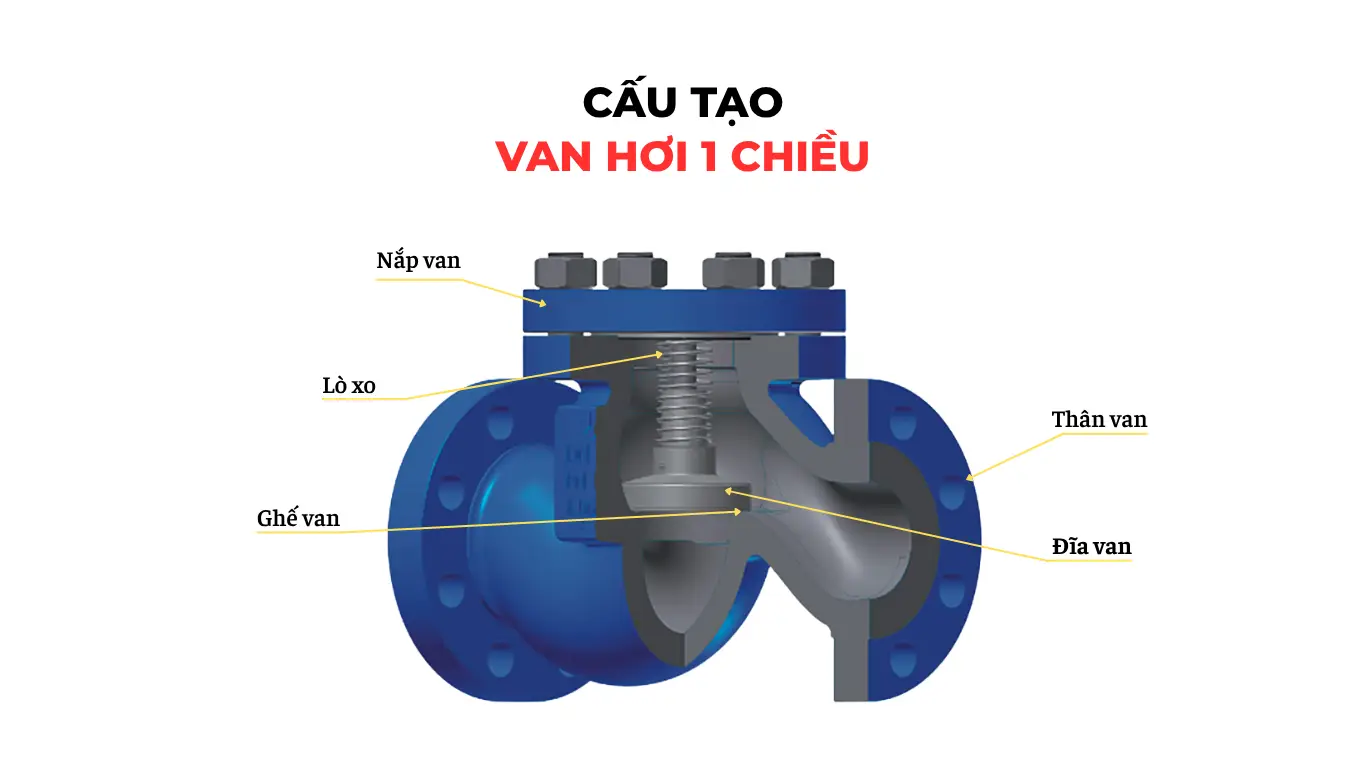

Basic Structure

Although there are several design variations, most steam check valves share the same main components:

- Valve body: The pressure-retaining outer shell, usually cast from cast iron, stainless steel, or heat-resistant steel.

- Disc or ball: The movable part that opens or closes the steam flow depending on the pressure direction.

- Seat: The contact surface where the disc or ball seals against when the valve is closed, ensuring a tight shutoff.

- Spring (optional): Provides additional closing force, allowing the valve to respond quickly when pressure drops or flow reverses.

- Bonnet (cover): Holds internal components in place and can be removed for inspection or maintenance.

Working Principle

A steam check valve operates based on the principle of pressure differential:

- When the inlet pressure is higher than the outlet pressure, the steam pushes the disc or ball off the seat, opening the valve and allowing steam to flow through.

- When the steam flow decreases or the outlet pressure becomes higher, the disc or ball automatically falls back or is pushed by a spring onto the seat, closing the valve and preventing reverse flow.

A special consideration in steam systems is the high-pressure fluctuation, which can cause water hammer if the valve closes too slowly. Therefore, many steam check valves are equipped with a spring to ensure faster, more reliable closure and allow installation in various orientations, including vertical piping.

Additionally, ball-type valves can offer a self-cleaning effect: the ball rotates slightly during opening and closing, helping to reduce dirt accumulation and uneven wear — making them ideal for steam containing light impurities.

Common Types of Steam Check Valves

Depending on mechanical design and system requirements, steam check valves are classified into several types. The following are the most common types, widely used in steam systems, boilers, and industrial heating networks:

Lift Check Valve

The lift check valve is specifically designed for high-pressure steam systems. Its disc moves vertically, lifting off the seat when steam flows in the correct direction and returning to the seat to close the valve when reverse flow occurs.

Advantages:

- Provides tight sealing, especially effective for high-pressure steam.

- Quick response when the flow stops.

- Robust and durable construction, suitable for industrial environments.

Disadvantages:

- Some types can only be installed horizontally (gravity-operated design).

- Higher pressure drop because the steam must lift the valve disc to flow.

Ứng dụng: Nồi hơi công nghiệp, hệ thống thu hồi condensate, trạm cấp hơi trung tâm.

Spring-Loaded Check Valve

The spring-loaded check valve uses a spring to assist in closing the disc or ball, increasing the closing speed and allowing flexible installation in any orientation: horizontal, vertical, or inclined.

Advantages:

- Fast closing reduces the risk of water hammer.

- Flexible installation in various orientations.

- Stable operation even under fluctuating steam flow.

Disadvantages:

- Higher opening pressure is required to overcome the spring force.

- May cause slight vibration if the opening pressure is not correctly selected.

Applications:

- Vertical steam pipelines.

- Locations with limited installation space.

- Steam systems with pressure fluctuations.

=> See more: What is a Spring Check Valve? Classification, Applications and How to Choose

Ball Check Valve

The ball check valve uses a ball as the closing element. When the steam flow is strong enough, the ball is lifted off the seat, allowing steam to pass through. When the flow weakens or reverses, the ball returns to the seat to seal the valve.

Advantages:

- The ball can rotate, providing a self-cleaning effect and even wear.

- Suitable for steam containing light impurities.

- Compact size, saving space in piping systems.

Disadvantages:

- May cause water hammer if additional damping is not used.

- Not suitable for very low-pressure steam systems.

Applications:

- Auxiliary steam lines.

- Condensate discharge lines.

- Steam environments with fine dust or light particulate matter.

Swing Check Valve (Less Common in Steam Systems)

The swing check valve features a hinged disc that opens in the direction of flow and closes when flow reverses.

-

Usage in steam systems: This type is generally less common for steam, as it reacts more slowly and is prone to water hammer. It is more commonly used in water pipelines.

=> See more: What is a check valve? Structure, principle and installation

You can refer to some one-way steam valve models at Bao Tin Steel:

Practical Applications of Steam Check Valves

Steam check valves are widely used in steam-operated systems to ensure safety, efficiency, and equipment longevity. Typical applications include:

- Industrial boilers – Used in food processing, textile dyeing, chemical plants, and steam power plants.

- Condensate recovery systems – Prevents backflow and protects pumps and piping.

- Vertical steam lines or high-level steam distribution – Ensures one-way steam flow and avoids water hammer.

- Heat treatment and heat exchange systems – Maintain proper steam flow and protect equipment.

- Steam distribution stations in factories – Controls and secures the steam supply to various sections.

Key Advantages of Steam Check Valves

- Effective Prevention of Reverse Steam Flow

Protects boilers, steam traps, pumps, and all upstream equipment from backflow and pressure surges (water hammer). - Automatic Operation Without External Power

Ensures stable and safe system operation even during power outages, as no electricity or external control is needed. - Fast Opening and Closing Response

Especially in spring-loaded valves, the valve reacts instantly to flow changes, minimising condensate buildup and sudden pressure spikes. - Good Sealing and High Pressure/Temperature Resistance

Typically made from ductile iron, stainless steel, or alloy steel, enabling reliable operation in heavy-duty industrial environments. - Versatile Designs – Flexible Installation

Lift, spring, or ball types suit various spaces and installation orientations (horizontal, vertical, inclined). - Cost-Effective and Long Service Life

Simple design with few moving parts makes maintenance and replacement easy, reducing long-term operational costs.

Disadvantages and Usage Considerations of Steam Check Valves

- Higher Pressure Drop

Steam must lift the disc or ball to pass through, causing a pressure loss—especially in spring-loaded valves. - Sensitive to Steam Impurities

Water containing scale, rust, or fine particles can jam the disc/ball, preventing proper sealing. Regular filtering and maintenance are required. - Orientation Limitations for Some Types

Gravity-assisted lift check valves (without spring) may only be installed horizontally and are unsuitable for vertical or inclined pipes. - Vibration if Incorrect Opening Pressure Selected

If the system pressure is below the valve’s minimum operating pressure, the disc may repeatedly open and close, causing vibration, seat wear, and early leakage. - No Visual Status Indicator

Valve position (open/closed) cannot be observed externally. For monitoring, additional pressure sensors or flow measurement devices may be needed.

Recommendations to Maximise Advantages and Minimize Disadvantages

To ensure optimal performance of steam check valves:

- Select the Correct Valve Type

Choose based on system pressure, temperature, and installation orientation. - Regularly Inspect Steam Filters and Operating Pressure

Prevents impurities from jamming the valve and ensures proper opening/closing. - Install According to Manufacturer Guidelines

Follow recommended installation procedures to avoid improper flow, vibration, or premature wear.

Experience in choosing the right one-way steam valve

Determine Correct Operating Parameters

- Operating Pressure

The valve must withstand the system’s maximum steam pressure. For high-pressure steam systems (above 10 bar), prioritise lift check valves or spring-loaded valves with thick, robust designs. - Steam Temperature

Select valves made of heat-resistant materials such as ductile iron, stainless steel 304/316, or forged steel for temperatures exceeding 150–200°C. - Steam Flow Rate

For large flow rates, choose larger-sized valves with wide openings to avoid flow restriction and excessive pressure drop.

Select Materials Suitable for the Operating Environment

- Ductile Iron (Cast Iron)

- Common and cost-effective.

- Suitable for clean steam at moderate temperatures.

- Stainless Steel

- Durable, corrosion-resistant, and heat-resistant.

- Ideal for steam containing minor impurities or CIP (Clean-in-Place) systems.

- Forged Steel

- Designed for very high temperature and pressure environments, e.g., thermal power plants or fluidised-bed boilers.

Select Valve Type Based on Installation Position and Orientation

-

Horizontal Installation with Stable Flow

-

Use gravity-assisted lift check valves.

-

-

Vertical Installation or Fluctuating Pressure

-

Prefer spring-loaded valves to ensure tight closure and minimise vibration.

-

-

Limited Space

-

Use ball check valves or short-body spring-loaded valves – compact design, easy to install.

-

-

Steam Containing Sediment or Fine Particles

-

Choose self-cleaning ball check valves to reduce disc/ball jamming.

-

Pay Attention to “Cracking Pressure”

- Each valve has a minimum pressure required to open (cracking pressure).

- For low-pressure systems (1–2 bar), select valves with low cracking pressure to avoid vibration or incomplete opening.

- For systems with strong pressure fluctuations, use valves with medium-strength springs or built-in dampers to enhance stability.

Prioritise Certified Products and Reputable Brands

-

Valves with clear origin and standard certifications (ISO, JIS, DIN, etc.) ensure material quality, tight sealing, and durability.

Some commonly used steam check valve brands in Vietnam include:

- Yoshitake (Japan)

- Shin Yi

- ARV

- FIVALCO

- High-quality Chinese valves

Installation and Maintenance Guidelines for Steam Check Valves

In addition to selecting the correct valve type, proper installation and regular maintenance are key factors that determine the valve’s lifespan and operational stability.

Below are the essential steps and considerations:

Steam Check Valve Installation Guidelines

Step 1: Inspect the Valve Before Installation

- Ensure the valve is free from cracks or damage; the disc/ball closes properly, and the spring operates smoothly.

- Clean flanges, threads, and pipe ends before installation.

- Verify the correct model, working pressure, and connection size.

Step 2: Determine the Correct Installation Direction

- An arrow on the valve body indicates the flow direction – installation must follow this arrow.

- Lift check valves without springs → install horizontally only.

- Spring-loaded valves → can be installed vertically, inclined, or horizontally, depending on pipe layout.

Step 3: Align and Tighten Connections

- Flanged valves: Place the gasket correctly and tighten bolts evenly in a star pattern to avoid deforming the valve body.

- Threaded valves: Use heat-resistant sealing tape; do not overtighten to prevent cracking.

Step 4: Post-Installation Check

- Perform a steam test to verify the valve opens and closes correctly.

- Ensure no leakage, no strong water hammer, and no unusual noise.

Periodic Maintenance and Cleaning

Recommended Maintenance Schedule

- Every 3–6 months for continuously operating steam systems.

- Or check whenever there are signs of valve vibration, backflow, or condensate accumulation in the pipe.

Maintenance Tasks

-

Disassemble and Clean the Valve:

-

Remove internal deposits such as steam scale, rust, or buildup around the disc/ball.

-

-

Inspect Valve Seat and Disc/Ball:

-

If there is deep wear or damage, replace or re-machine as necessary.

-

-

Check Spring Tension (if applicable):

-

If the spring is weak or broken, replace it to avoid slow valve closure.

-

-

Lubricate Sliding Stem (if vertical motion valve):

-

Apply high-temperature resistant grease lightly to ensure smooth operation.

-

Safety Notes

- Always vent pressure, isolate the steam line, and wait until fully cooled before disassembling the valve.

- Wear full personal protective equipment (PPE) when inspecting or cleaning valves in high-pressure systems.

Recommendations

- Install a steam filter or trap at the inlet to prevent debris from entering the valve.

- For systems with multiple branches or large pressure fluctuations, install pressure gauges at the valve inlet/outlet to monitor valve status.

- Keep a detailed operation log to anticipate the timing for component replacement.

Conclusion

Although compact, the steam check valve plays a crucial role in industrial steam systems. From preventing backflow, reducing water hammer risk, to protecting equipment such as boilers, pumps, and steam traps, this valve helps maintain system efficiency, extend equipment lifespan, and ensure operational safety.

However, each system has specific technical requirements regarding pressure, temperature, installation orientation, and medium quality. Therefore, users must choose the correct valve type, material, and specifications to optimise performance and minimise long-term maintenance costs.

Need consultation or a quote for steam check valves?

Bao Tin Steel – a reliable supplier of industrial valves with full CO-CQ certification, technical support, and nationwide delivery.

Contact us to:

- Get expert advice for selecting valves based on your actual system

- Receive competitive quotes for sizes DN15–DN200

Technical & Sales Hotline: 0932 059 176

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ