The swing check valve is an essential component in modern piping systems — from water supply and drainage, fire protection, and HVAC to chemical and energy industries. With its fully automatic backflow prevention capability, this valve protects pumps, minimises the risk of water hammer, and effectively maintains system pressure stability.

Requiring no electricity or external control, the valve operates solely based on flow pressure and gravity, offering high reliability even under continuous operation. At Thép Bảo Tín, we offer a wide range of swing check valves made of cast iron, stainless steel, and brass — suitable for both residential projects and heavy-duty industrial plants.

This article will help you better understand the structure, working principle, applications, advantages and disadvantages of swing check valves, and will also provide recommendations for selecting the right product based on specific system conditions.

Stay tuned!

What is a Swing Check Valve?

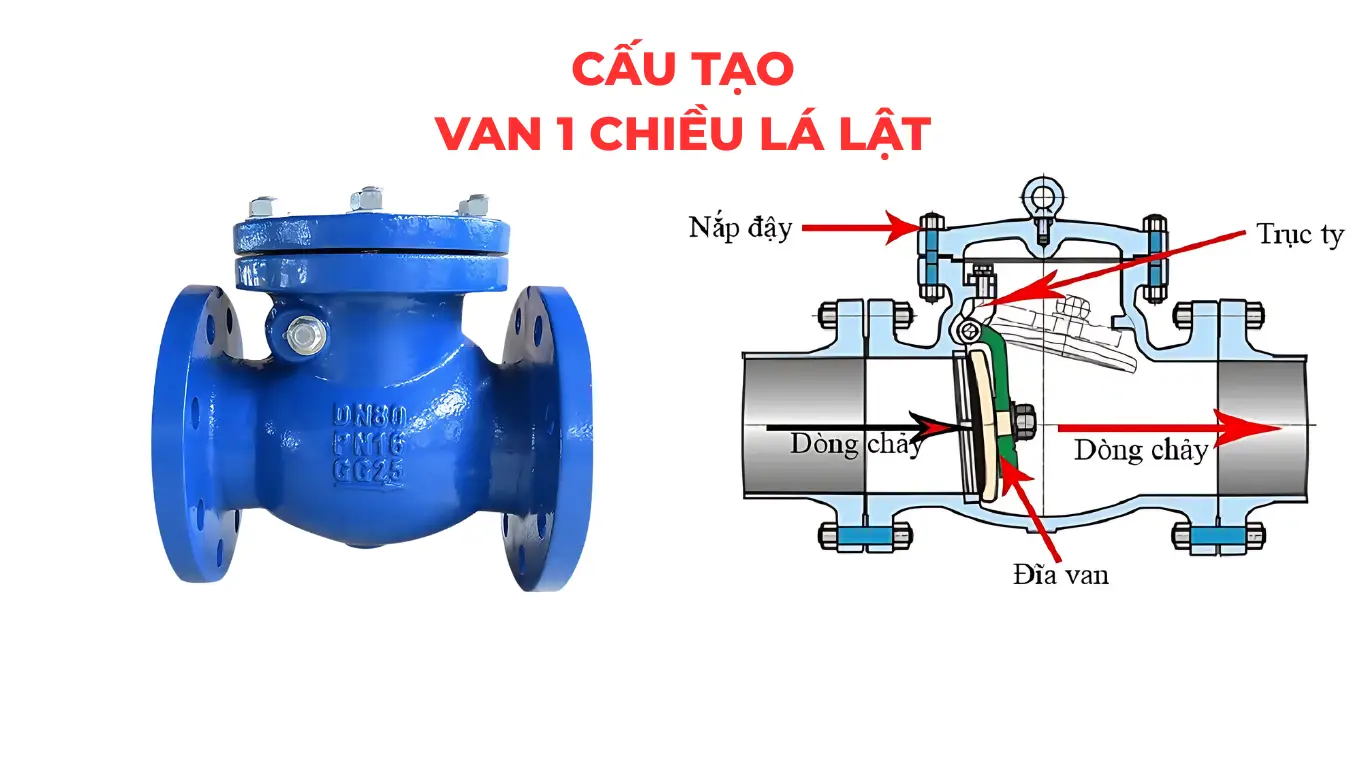

A swing check valve is a specialised type of valve designed to allow the flow of liquids or gases in only one direction, and to automatically close when the flow reverses. Its basic structure includes a round disc (also called a flap or disc) connected to a hinge, operating on a “swing” mechanism — it opens when the flow moves in the forward direction and closes due to gravity or back pressure when the flow reverses.

This simple mechanism allows the valve to operate without any external power source, resulting in a low risk of malfunction and making it particularly suitable for systems that require high continuity and stability.

Some swing check valve models currently distributed by Bao Tin Steel include:

Structure and operating principle

| Component | Technical Function |

|---|---|

| Valve Body | Outer casing that protects the internal mechanism, usually made of cast iron, stainless steel, or brass. |

| Bonnet | Easily removable cover for inspecting or replacing the disc and hinge. |

| Disc | Opens/closes according to flow direction; circular shape; attached to the hinge. |

| Hinge | Allows the disc to swing flexibly when flow occurs. |

| Seat (Seal Ring) | Creates a tight sealing surface when the disc closes; can be metal or a soft material. |

| Hinge Pin | Connects the hinge to the valve body, enabling a stable pivoting/swinging motion. |

This simple yet precise structure enables the swing check valve to operate reliably and be easily maintained even under harsh working conditions.

If you need a valve that is easy to maintain with a replaceable disc accessible through the bonnet, you may consider the ARV Cast Iron Swing Check Valve — designed according to the BS5153 standard, featuring easy disassembly and seat replacement.

Working Principle

The swing check valve operates based on the pressure difference between the two ends of the valve and the weight of the valve disc:

- When the flow moves in the correct (forward) direction, the pressure from the upstream side pushes the disc open, allowing the fluid to pass through.

- When the flow stops or reverses, the pressure decreases, combined with back pressure from downstream and the weight of the disc, causing the disc to close tightly, completely preventing reverse flow.

This “swing-close” mechanism requires no external power and is suitable for continuously operating systems where frequent supervision is not possible. Some improved designs may include a spring for faster closing or a lever and counterweight to reduce water hammer effects.

Advantages and Disadvantages of Swing Check Valves

Key Technical Advantages

Swing check valves are widely favoured in industrial systems due to the following operational benefits:

- Low pressure loss: Thanks to the flow-driven opening mechanism and a large flow area, these valves generate minimal resistance, making them ideal for high-flow systems such as water supply, fire protection (FIRE FIGHTING), and wastewater treatment.

- Fully automatic operation: No need for electrical power or remote control. The valve functions solely by pressure difference and gravity, minimising risks related to control device failures.

- Easy maintenance and low cost: With a simple design consisting of only a few moving parts, these valves experience fewer breakdowns and are easy to disassemble for disc or seat replacement when necessary.

- Tolerance to mildly contaminated media: They maintain stable operation even with slightly dirty flow containing slurry, fibres, or suspended particles, due to the flexible swinging disc mechanism, which reduces the risk of jamming.

- Compatibility with various materials and connections: Manufactured from cast iron, stainless steel, brass, PVC, etc., and available with flanged, threaded, or wafer connections to meet diverse system requirements.

Bao Tin Steel currently distributes a variety of swing check valves with cast iron flanged bodies, 304 stainless steel, and 316 stainless steel, suitable for environments involving clean water, seawater, chemicals, and high temperatures.

Technical Disadvantages to Note

Despite many advantages, swing check valves still have certain limitations that engineers should consider when designing systems:

- Prone to water hammer: When the flow suddenly stops, the disc can slam shut against the seat, causing a large pressure shock. This is especially common when pumps stop abruptly or in long pipelines with high flow velocity.

- Slower closing time compared to spring check valves: Because closing relies on gravity or back pressure, the response time is slower than spring check valves, which can lead to pressure surges if the flow changes suddenly.

- Requires larger installation space: The disc needs enough room to fully swing open, making these valves unsuitable for narrow pipes or confined spaces.

- Not suitable for installation against the flow direction (horizontal upside down): The valve only works properly when installed horizontally (with horizontal flow) or vertically (flow going upwards). Incorrect installation can prevent the disc from closing.

Solution to Reduce Water Hammer:

When installing in locations prone to water hammer, it is advisable to use valves equipped with a lever, counterweight, or spring assist.

Types of Swing Check Valves

Although all operate on the same principle of the valve disc swinging open and closed based on flow pressure, in practice, swing check valves come in various variants to meet diverse technical requirements and working environments such as water supply and drainage systems, fire protection, chemical processing, wastewater treatment, HVAC, and more.

Below are the typical valve types that Thép Bảo Tín currently supplies, complete with CO-CQ and technical certifications:

Cast Iron Swing Check Valve

- Material: Ductile iron or grey cast iron, coated with anti-corrosion epoxy

- Working Pressure: PN10 / PN16

- Applications: Water supply systems, fire protection (FIRE FIGHTING), HVAC, construction projects

- Advantages: Cost-effective, widely used in technical infrastructure systems

Stainless Steel Swing Check Valve

- Material: Stainless steel 304, stainless steel 316 – excellent corrosion resistance

- Working Temperature: Up to 180°C

- Applications: Food processing plants, clean water, mild chemicals, RO water treatment systems

- Advantages: Durable, rust-resistant, suitable for corrosive environments

Brass Swing Check Valve

- Material: Solid brass with good corrosion resistance in clean water

- Common Sizes: DN15 – DN50

- Applications: Residential systems, water heaters, household pumps, HVAC systems (heating, ventilation, air conditioning)

- Advantages: Compact size, easy threaded installation, competitive price

Steel Swing Check Valve

- Material: Carbon steel (WCB), alloy steel

- Applications: Steam pipelines, oil, gas, and high-pressure systems

- Standards: ANSI 150 – 300 – 600

- Advantages: High-pressure resistance, suitable for high-temperature and high-pressure environments

Plastic Swing Check Valve

- Material: uPVC, CPVC, PVDF

- Applications: Low-concentration chemical systems, water treatment, agriculture, or applications with low temperature and pressure.

- Advantages: Lightweight, highly corrosion-resistant, easy to install.

Threaded Swing Check Valve

- Valve Sizes: DN15 – DN50

- Thread Standards: BSP, NPT

- Advantages: Quick installation, suitable for tight spaces and residential systems.

- Suitable for: Household water pumps, air conditioners, auxiliary systems.

Flanged Swing Check Valve

- Valve Sizes: DN50 – DN300+

- Flange Standards: JIS, BS, ANSI

- Advantages: High sealing capability, safe for high-pressure systems.

- Suitable for: Industrial water supply, fire protection systems, water treatment plants.

Technical Notes:

When selecting a valve based on material and connection type, consider:

- The type of media (water, gas, chemicals)

- Operating pressure and temperature

- Pipe diameter and connection standards

- Practical application in various industries

Swing check valves not only control reverse flow but also play a critical role in protecting equipment, maintaining pressure, stabilising flow, and enhancing overall system safety. Typical application areas include:

- Water supply and wastewater treatment systems: Usually installed after clean water pumps, wastewater pumps, pressure control valves, tanks, and sumps.

- Fire Protection Systems (FIRE FIGHTING): Installed after main fire pumps or booster pumps, connected to alarm valves and sprinkler piping.

- Chemical and Food Industry

- HVAC – Industrial air conditioning systems: Installed on chilled water return lines and coil supply lines.

- Energy – Thermal power – Oil & Gas industry: Recommended to use WCB (carbon steel) swing check valves with Stellite-coated seats for steam, heat transfer oil, and high-pressure gas applications.

- Well water pumps and residential systems.

Tips for Choosing the Right Swing Check Valve

Selecting the right type of swing check valve not only ensures smooth system operation but also reduces technical risks such as water hammer, pump damage, and pressure leakage, while extending equipment lifespan.

Choose According to the Type of Working Medium

- Clean water, domestic water: Use cast iron, brass, or stainless steel valves

- Seawater, mild chemicals: Prefer stainless steel 316 or corrosion-resistant uPVC plastic valves

- Oil, gas, steam: Select WCB steel or alloy steel valves with Stellite-coated seats

- Food industry, RO water: Use stainless steel 304/316 valves with clean, rust-free surfaces

Choose According to Working Pressure & Temperature

| Environment | Recommended Materials & Valve Standards |

|---|---|

| Low pressure < 10 bar | Cast iron, plastic, brass (PN10–PN16) |

| Medium pressure 10–20 bar | Stainless steel, thick cast iron, metal or PTFE seats |

| High pressure > 20 bar | WCB forged steel, wear-resistant alloy seats |

| Temperature > 150°C | Stainless steel, alloy steel, metal seats |

Choose According to Pipe Size

- DN15–DN50: Use threaded valves (usually small brass or stainless steel valves)

- DN65 and above: Use flanged valves (cast iron, stainless steel, steel)

Choose According to Space and Installation Location

- Tight spaces: Prefer wafer or threaded swing check valves

- Wide spaces, easy maintenance: Choose flanged valves

- Locations prone to impact: Use valves with an internal hinge cover (better disc protection)

Note: The valve disc requires space to swing, so avoid installing the valve too close to elbows, tees, or shut-off valves.

Choose According to Brand and Technical Certifications

- Prioritise reputable brands with CO-CQ and certifications meeting BS, JIS, ANSI, API 594 standards

- For fire protection systems, select valves with fire safety certification (FIRE FIGHTING approved), compatible with alarm valves and gate valves

Proper Installation Guide for Swing Check Valves

Besides selecting the right type of swing check valve, the installation process must be carried out correctly by qualified personnel. This ensures stable valve operation, prevents leaks, avoids water hammer, and eliminates incomplete opening or closing.

Below is the recommended installation guide according to technical recommendations and industry standards:

Pre-Installation Checks

- Carefully read the flow direction indicated by the raised or printed arrow on the valve body.

- Open and check that the valve disc swings freely without sticking or warping.

- Clean both flanges or threaded ends, removing dust, debris, and foreign objects inside the pipe.

- Inspect the sealing seat to ensure it is not deformed during transport.

Notes:

- For threaded valves: Use Teflon tape in the correct direction and avoid wrapping too thickly to prevent thread cracking.

- For flanged valves: Check that flange faces are concentric and flat; use proper rubber or PTFE gaskets.

Choosing the Proper Installation Location

- Ideal position: Install the valve horizontally or vertically with the flow direction going upward.

- Do not install: Vertically with the flow direction downward, as this causes the disc to stay open and not seal properly.

In horizontal pipes, the valve disc hinge must be positioned on the upper side of the pipe axis to ensure gravity assists in closing the valve effectively.

Standard Installation Steps

a. For Flanged Valves:

- Place the valve between the two fixed flanges on the pipeline.

- Align the valve and pipe concentrically to avoid misalignment.

- Position the gasket correctly (usually EPDM or PTFE).

- Insert bolts and tighten them evenly in a star pattern (5–6 points) to prevent warping.

- Check manually: the valve disc should swing lightly without obstruction.

b. For Threaded Valves:

- Apply thread sealant or Teflon tape in the correct thread direction.

- Tighten by hand first, then use a wrench—do not overtighten to avoid cracking the valve body.

- Avoid applying force directly to the valve disc.

Post-Installation Checks

- Pressure tightness test: Use a pressure testing machine to check for leaks and proper opening/closing response.

- Operational observation: When the pump runs, the disc should open fully; when stopped, the disc should close tightly.

- No loud banging noise should occur when the valve closes—if it does, inspect for water hammer.

Important Notes

- Do not use the valve as a support point when lifting or lowering pipes to prevent body cracking.

- Ensure a straight pipe length of at least 5D upstream and 10D downstream of the valve to stabilise flow.

- Periodically open the valve bonnet to inspect and clean the disc and seat to maintain performance.

Maintenance and Troubleshooting

Although swing check valves have simple construction and few failures, regular inspection and maintenance are necessary to ensure stable long-term operation—especially in environments with sediment, corrosive fluids, or fluctuating flow. Below are maintenance tips and common troubleshooting guidelines:

Periodic Maintenance

Recommended frequency:

- External inspection: once per month

- Internal inspection (disc, seat): every 6–12 months, depending on operating conditions

Inspection contents:

- Condition of the valve disc: check for wear, misalignment, or jamming due to debris

- Seal seat: check for uneven wear, deformation, cracks, or sediment buildup

- Hinge and pin: check for rust, sticking, or rough rotation

- Sealing gasket, bolts, and bonnet: check for leaks

Recommendation: For cast iron or stainless steel valves used in wastewater, clean periodically with mild chemicals or high-pressure water to remove sediment buildup on the disc.

Common Problems and Solutions

-

Valve does not close tightly / leaks

-

Cause: Worn seat, sediment buildup, warped or deformed disc

-

Solution: Remove the bonnet, clean or replace the seat and disc

-

-

Valve stuck – disc does not open/close

-

Cause: Hard objects (stones, debris) stuck inside; rusty or misaligned hinge

-

Solution: Disassemble valve, inspect internally, replace pin or disc if bent/broken

-

-

Loud banging noise when closing – water hammer

-

Cause: Valve closes too slowly → reverse flow hits disc forcefully

-

Solution:

-

Reduce closing speed by installing a valve with a spring, counterweight, or lever

-

Consider installing pressure relief valves or air release valves at pipe ends

-

-

-

Valve continuously rattles (chattering)

-

Cause: Flow too low, causing unstable disc oscillation

-

Solution: Check design flow rate or replace valve with lighter disc or spring-assisted type

-

When to Replace?

- Disc severely corroded, broken pin, or deformed, causing loss of sealing

- Seat no longer provides proper sealing pressure → continuous leakage

- The valve body cracked due to abnormal pressure or an installation error

For valves installed for over 5 years, especially in chemical or high-temperature environments, plan periodic replacement to avoid sudden failures.

Technical Support Services from Thép Bảo Tín

- Advice on the correct valve type according to actual conditions

- Stock of genuine replacement valves with full CO-CQ certificates

- Technical consultation on-site, provide drawings and project documentation

Conclusion

Swing check valves are fundamental one-way valves playing a crucial role in protecting the safety of industrial piping systems. From potable water, wastewater treatment, to fire protection, HVAC, food, chemical, and energy industries, swing check valves are trusted for their simple design, easy maintenance, effective backflow prevention, and long service life.

However, for optimal performance, businesses must select the right valve type based on medium, pressure, temperature, installation space, and connection standards. Proper installation and regular maintenance are essential to extend service life and minimise operational failures.

Need help choosing the right swing check valve for your system?

Let Bao Tin Steel assist you:

- Wide range of swing check valves: cast iron, stainless steel, brass, steel, plastic

- Full connection types: flanged, threaded, stock available from DN15 to DN300

- On-site technical support, provide CO-CQ, drawings, and full project documents

- Competitive prices – fast nationwide delivery

Contact Bao Tin Steel now for quotes and technical advice:

Hotline: 0932 059 176

Email: bts@thepbaotin.com

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ