Steel truss drawings are very important for steel truss projects. Making these drawings requires a professional, experienced, and knowledgeable person about the project. If you are still confused, this article will help you understand more about steel trusses. At the same time, refer to the highly appreciated drawings.

Before going into details, do you know what a truss is? What is a steel truss?

What is a truss?

Currently, the trusses used include two main types: shaped steel trusses and galvanized steel boxes (square steel, rectangular steel). And in today’s article, we will focus on steel square trusses for roof systems. Specifically, corrugated iron roof trusses and tile roof trusses. Let’s see what’s special about them!

How important is the steel truss drawing?

Steel truss drawings are very important because they are documents that provide detailed information about the steel truss system in the project. Including size, structure, location of components, etc. This drawing is the basis for manufacturing, installing, and ensuring the quality of the roof.

A square steel drawing will have information such a

- General information: Project name, design unit, designer, design date.

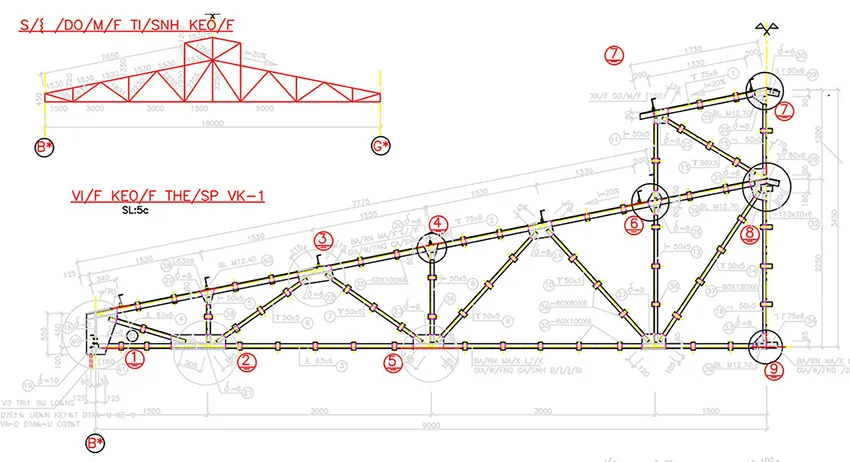

- Overall drawing: truss system, size system, location of trusses, columns, beams, steel bars.

- Detailed drawings: truss components, dimensions, materials, accessories, assembly diagram of components.

- Bill of Materials

- Drawing Notes (if any)

A complete steel truss drawing will ensure the quality and durability of the project. The more detailed the drawing, the more convenient, simple, and fast the construction will be. At the same time, it also helps contractors to buy all the necessary materials accurately and completely and save costs for the project.

Calculation of steel trusses

Before drawing the steel truss, the designer needs to calculate the truss. From here, the designer will have specific data to complete the steel truss drawing. Specifically, it is the process of determining the size, thickness, and cross-section of the truss components.

This step helps us ensure that the roof can withstand the load and meet the technical requirements of the project. The span of the steel trusses will be different, such as 6 m, 7 m, 8m, 10 m, 12 m, 16 m, 20 m,…. It depends on the size of the corresponding steel purlin used.

Different trusses make the cross-section of the components different. At this time, the designer also needs to flexibly handle the changes to ensure the connections. Along with that, we should choose the shortest span when arranging the truss and ensure an even distribution of force on the truss system.

Top 5 highly rated steel truss drawings

Answer questions

What is the difference between trusses and purlins?

-> Below is a comparison table of trusses and square steel to help customers grasp information more easily and fully:

| Features | the truss | Purlin |

| Main function | Main bearing | Support for trusses |

| Location | Along the roof ridge | Perpendicular to the truss |

| Role | Create a load-bearing frame | Create a roof support plane |

Why are square steel trusses chosen so much?

Because the current steel truss is usually 10 m, 12 m, 15 m, and 18 m long,… the 12 m steel truss is sought after and used more commonly. This is because the 12 m length is suitable for many types of construction. At the same time, it minimizes the joints. Thereby, improving the aesthetic factors of the roof.

Above is the information about the steel truss drawing. Hopefully, the information that Bao Tin Steel provides will be useful to everyone. If you need support in quoting the price of steel products, please contact us. Hotline: 0932 059 176!

Tiger Steel is a subsidiary of Bao Tin Steel

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ