What is an ERW steel pipe? What is the production process like? Technical specifications and where to buy ERW steel pipes to ensure quality and affordable prices? All of these questions will be answered by Bao Tin Steel in the article below.

What is an ERW steel pipe?

ERW steel pipe (Electric Resistance Welding Pipes.) is a type of welded steel pipe made by passing a high-frequency electric current through the edges of a steel strip or plate. Heat them to the point of melting, then weld them together. ERW stands for Electric Resistance Welding Pipes.

Based on the pipe welding technique, ERW steel pipes are divided into 2 types:

- ERW steel pipes welded by alternating current (AC)

- ERW steel pipes welded by direct current (DC)

Welded steel pipes are the most advanced and economical type of steel pipe in the field of storing and transporting oil and gas.

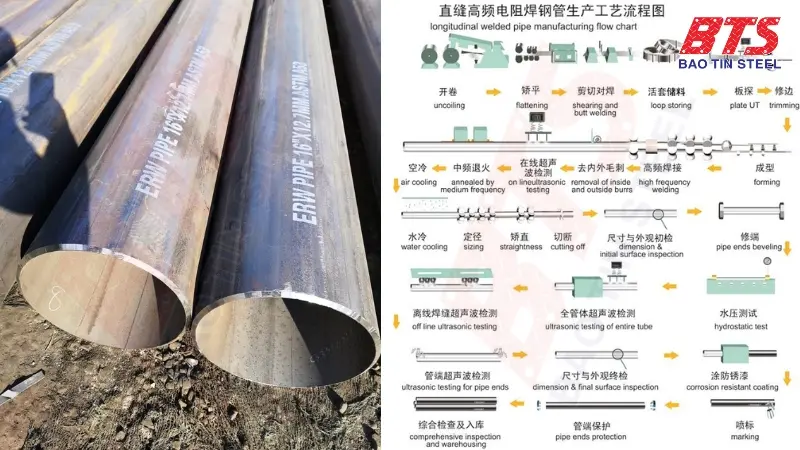

ERW steel pipe production process

Electric current flows through the contact surface of the welding area during the welding process of ERW pipes, generating heat. It heats the two edges of the steel to the point where one edge can form a bond.

Below is the basic production process of resistance-welded steel pipes:

- Prepare steel coil.

- Shaping. The prepared steel strip is then passed through a forming roller to shape it into a cylindrical tube. The edges of the strip are joined together to form a longitudinal seam.

- Resistance welding. The strip formed with a longitudinal seam is passed through a set of high-frequency induction coils. High-frequency electric current is applied to the edges of the strip, heating them and bringing them to the melting point.

- Weld. When the edges of the strip reach the melting point, pressure is applied to forge the edges together. Create a solid weld. High-frequency current ensures fast heating, allowing efficient welding.

- Sizing and straightening. The resistance-welded tube undergoes sizing and straightening operations to achieve the desired size and eliminate any distortion.

- Cut and finish. After sizing and straightening, the ERW-resistant welded steel pipe is cut to the desired length.

- Check. ERW steel pipes are subjected to many quality checks and tests.

Surface treatment and coating.

Specifications of ERW steel pipes

Technical specifications of Electric Resistance Welding Pipes

ERW steel pipes are manufactured in compliance with various national and international standards to ensure quality. Below are the basic technical parameters of resistance-welded steel pipes:

- Diameter: phi 10 – phi 610 (can import larger diameter steel pipes)

- Length: 6m, 12m

- Origin: China, Korea, Japan, Vietnam…..

- Manufacturing materials: Carbon steel, stainless steel, alloy steel, etc.

- Production standards: API 5L, ASTM A53, A106, EN10219, BS1387, DIN EN 10217,….

Bảng quy cách ống thép ERW

Để giúp các bạn dễ hình dung hơn, Thép Bảo Tín chia sẻ bảng quy cách ống thép ERW có mặt tại Thép Bảo Tín.

| Nominal pipe size | Outside Diameter |

Nominal wall thickness (mm)

|

|||||||||||

| A (DN) | B (INCH) | ASME | SCH10 | SCH20 | SCH30 | STD | SCH40 | SCH60 | XS | SCH80 | SCH120 | SCH160 | XXS |

| 15 | 1/2 | 21.3 | 2.11 | 2.41 | 2.77 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | |||

| 20 | 3/4 | 26.7 | 2.11 | 2.41 | 2.87 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | |||

| 25 | 1 | 33.4 | 2.77 | 2.9 | 3.38 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | |||

| 32 | 1 1/4 | 42.2 | 2.77 | 2.97 | 3.56 | 3.56 | 4.85 | 4.85 | 6.35 | 9.7 | |||

| 40 | 1 1/2 | 48.3 | 2.77 | 3.18 | 3.68 | 3.68 | 5.08 | 5.08 | 7.14 | 10.151 | |||

| 50 | 2 | 60.3 | 2.77 | 3.18 | 3.91 | 3.91 | 5.54 | 5.54 | 8.74 | 11.07 | |||

| 65 | 2 1/2 | 73 | 3.05 | 3.18 | 5.16 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 | |||

| 80 | 3 | 88.9 | 3.05 | 4.78 | 5.49 | 5.49 | 7.62 | 7.62 | 11.13 | 15.25 | |||

| 90 | 3 1/2 | 101.6 | 3.05 | 4.78 | 5.74 | 5.74 | 8.08 | 8.08 | |||||

| 100 | 4 | 114.3 | 3.05 | 4.78 | 6.02 | 6.02 | 8.56 | 8.56 | 11.13 | 13.49 | 17.12 | ||

| 125 | 5 | 141.3 | 3.4 | 4.78 | 6.55 | 6.55 | 9.53 | 9.53 | 12.7 | 15.88 | 19.05 | ||

| 150 | 6 | 168.3 | 3.4 | 7.11 | 7.11 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | |||

| 200 | 8 | 219.1 | 3.76 | 6.35 | 7.07 | 8.18 | 8.18 | 10.31 | 12.7 | 12.7 | 18.26 | 23.01 | 22.23 |

| 250 | 10 | 273 | 4.15 | 6.35 | 7.8 | 9.27 | 9.27 | 12.7 | 12.7 | 15.09 | 21.44 | 25.58 | 25.4 |

| 300 | 12 | 323.8 | 4.57 | 6.35 | 8.38 | 9.53 | 10.31 | 14.27 | 12.7 | 17.48 | 25.4 | 33.32 | 25.4 |

| 350 | 14 | 355.6 | 6.35 | 7.92 | 9.53 | 9.53 | 11.13 | 15.09 | 12.7 | 19.05 | 27.79 | 35.71 | |

| 400 | 16 | 406.4 | 6.35 | 7.92 | 9.53 | 9.53 | 12.7 | 16.66 | 12.7 | 21.44 | 30.96 | 40.19 | |

| 450 | 18 | 457.2 | 6.35 | 7.92 | 11.13 | 9.53 | 14.27 | 19.05 | 12.7 | 23.83 | 34.93 | 45.24 | |

| 500 | 20 | 508 | 6.35 | 9.53 | 12.7 | 9.53 | 15.09 | 20.62 | 12.7 | 26.19 | 38.1 | 50.01 | |

| 550 | 22 | 558.8 | 6.35 | 9.53 | 12.7 | 9.53 | 15.09 | 22.23 | 12.7 | 28.58 | 41.28 | 53.98 | |

| 600 | 24 | 609.6 | 6.35 | 9.53 | 14.27 | 9.53 | 17.48 | 24.61 | 12.7 | 30.96 | 46.02 | 59.54 | |

| 650 | 26 | 660.4 | 7.92 | 12.7 | 9.53 | 12.7 | |||||||

| 700 | 28 | 711.2 | 7.92 | 12.7 | 15.88 | 9.53 | 12.7 | ||||||

| 750 | 30 | 762 | 7.92 | 12.7 | 15.88 | 9.53 | 12.7 | ||||||

| 800 | 32 | 812.8 | 7.92 | 12.7 | 15.88 | 9.53 | 12.7 | ||||||

Frequently asked questions about resistance welded steel pipes

| Surface coating of ERW pipes | Depending on the conditions of exposure to the surrounding environment, the surface of the pipe can be left bare, plated, or painted to meet the requirements for mechanical and chemical durability. |

| Resistance welding | An electric current is passed between the two edges of the steel to heat the steel to a point at which the edges are pressed together to form a bond without welding material. This manufacturing process initially used low-frequency alternating current to heat the edges. This low-frequency process was used from the 1920s until the 1970s. In 1970, the low-frequency process was replaced by a high-frequency ERW process that produced higher-quality welds. |

| Difference between ERW, SSAW, LSAW | LSAW steel pipe is a longitudinal submerged arc welded pipe, also known as SAWL pipe. A spiral-submerged arc welding (SSAW) steel pipe is a submerged arc welded pipe with a spiral weld called an SSAW pipe. ERW steel pipes are submerged welded steel pipes in high-frequency resistance environments (ERW stands for Electric Resistance Welding Pipes). |

| Application of resistance welded pipes | ERW steel pipes are used in common applications: oil and gas industry, plumbing, structures, construction, automotive industry, etc. |

| ERW pipe weld contour shape | The weld of the steel pipe will be smoothed. |

| ERW pipe product line | Resistance-welded steel pipes vary in quality, wall thickness, diameter, standards, etc. |

If you need to buy quality-assured ERW steel pipes for your project. Please contact the Hotline of Bao Tin Steel today. Our sales staff is ready to advise you 24/7.

Tiger Steel is a branch of Bao Tin Steel.

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ