A boiler safety valve is a mandatory device in high-pressure systems such as boilers, industrial water pumps, and water heaters. Its main function is to automatically release pressure when it exceeds the safe threshold. This helps protect the equipment and ensures the safety of operators.

Incorrect installation can prevent the valve from functioning properly, which may lead to continuous steam release, hot water leakage, or, more seriously, pressure explosions. These incidents can cause significant damage to both people and property.

In this article, Bao Tín Steel will guide you on how to correctly install safety valves for boilers, pumps, and water heaters. The instructions are designed to be technically accurate, easy to follow, and ensure long-term stable operation.

How to Install Safety Valves for Boilers, Pumps, and Water Heaters

To ensure the safety valve works effectively and performs its pressure relief function correctly, it must be installed properly from the start. Below is a detailed installation guide for each specific type of equipment

General Requirements Before Installation

Before installing a safety valve, it’s important to make thorough preparations and follow some basic principles:

- Choose the correct type of valve: Each system requires a specific type of safety valve based on material, size, and set pressure. Make sure the valve you select is suitable for the equipment (boiler, pump, or water heater) and matches the system’s technical specifications.

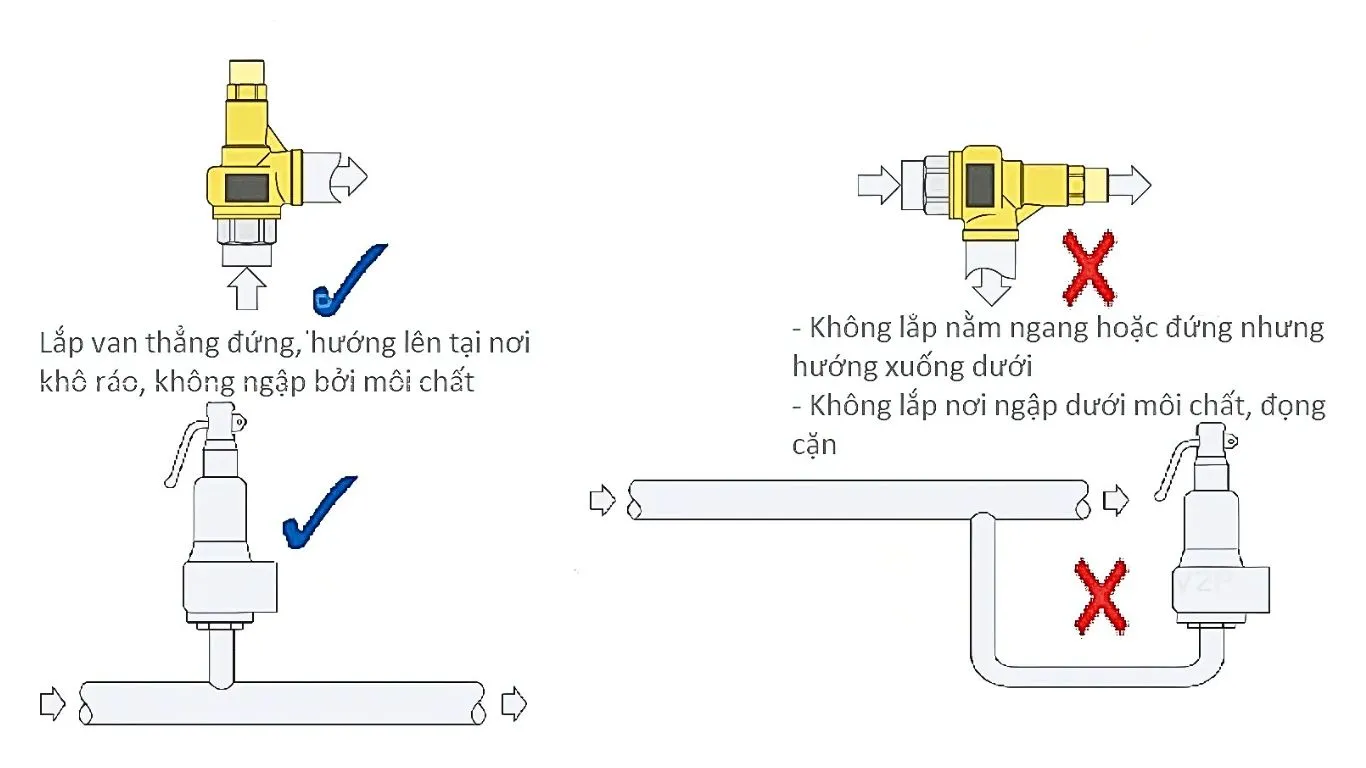

- Install at the highest point: The safety valve should be installed at the highest point of the equipment or piping system. This ensures it can promptly detect and release excess pressure when needed.

- Install a pressure gauge near the valve: A pressure gauge will help you monitor the system’s pressure. This allows you to verify whether the valve is functioning properly and quickly respond if any irregularities occur.

How to install a safety valve for a boiler

- Installation position: The ideal position for the safety valve is at the top of the boiler, near the steam generation area. This is where pressure tends to rise the fastest, so the valve must be located here to release excess pressure promptly.

- Installation direction: Pay attention to the arrow indicating the flow direction marked on the valve body. Install the valve according to these directions to ensure proper and reliable operation.

- Connect a discharge pipe to the outside: Hot steam released from the valve can cause serious burns if it escapes directly toward people. Therefore, it is essential to attach a discharge pipe to safely vent the steam to a well-ventilated and secure area.

Never install a shut-off valve between the boiler and the safety valve.

This is extremely dangerous. If the shut-off valve is closed, the safety valve will not be able to release pressure, leading to a high risk of explosion.

🔥🔥 See now some types of safety valves sold at Bao Tin Steel

ROBO Safety Valve, available in a wide range of sizes from DN50 to DN300, helps ensure your system operates reliably. It provides enhanced safety and long service life.

How to install a safety valve for a pump

- Installation position: The valve should be installed on the pump’s discharge pipe or at the outlet of the pressure accumulator. This is typically the area with the highest pressure when the pump is operating.

- Protective function: In the event of an abnormal pressure increase (due to blockage, valve closure, or malfunction), the safety valve will automatically release pressure to prevent pipe rupture, leakage, or damage to the pump seal.

- Use with a pressure-reducing valve: If the system frequently experiences large pressure fluctuations, consider installing a pressure-reducing valve alongside the safety valve to help regulate pressure more steadily. This improves the safety valve’s accuracy and extends its service life.

How to Install a Safety Valve for Water Heaters

- Installation position: The safety valve should be installed at the cold water inlet, where water enters the tank. When the water is heated, its expanding volume increases the pressure inside the tank, and the valve will automatically release pressure to balance it.

- Automatic pressure release function: This mechanism is crucial to prevent water heater explosions, especially when the thermostat or temperature control device malfunctions.

- Discharge outlet caution: Do not block the valve’s discharge outlet. Instead, connect a discharge pipe to safely direct the water to a floor drain or a safe drainage area to avoid flooding, dampness, or water spraying into the surrounding area.

Common Mistakes When Installing Safety Valves

Although safety valves are crucial devices for protecting systems from overpressure, incorrect installation is still quite common in practice. This can cause the valve to malfunction or create hidden safety hazards. Below are the most frequent mistakes and their potential consequences:

Installing the valve in the wrong flow direction

This is a simple but very serious mistake. There is always an arrow on the valve body indicating the flow direction. If installed backwards:

- The valve will not open at the right time, losing its pressure relief function.

- High-pressure steam or water will be trapped in the system, which can cause pipe bulging, bursting, or equipment damage.

👉 How to fix it: Always carefully check the markings on the valve body and ensure it is installed according to the correct flow direction.

Installing a shut-off valve between the equipment and the safety valve

Many people think that adding a shut-off valve helps with maintenance or discharge control. However, this is extremely dangerous:

- If the shut-off valve is accidentally closed, the safety valve will be disabled and unable to release pressure even when it rises dangerously high.

- In cases where the boiler or water heater experiences overpressure without a pressure relief path, the system can explode, causing severe damage.

👉 Safety principle: Never install a shut-off valve between the equipment and the safety valve. If isolation is necessary, use other safe methods, such as physically removing the valve.

Lack of Regular Inspection

Safety valves operate fully automatically, so they are often neglected during maintenance. Failure to perform regular inspections can lead to:

- The valve becomes stuck, corroded, or fails to open when needed.

- Minor leaks that persist, causing pressure loss and energy waste.

- Undetected valve malfunctions before scheduled inspections or major incidents occur.

👉 Solutions:

- Conduct regular inspections every 3–6 months, depending on the operating environment.

- Perform manual discharge tests if the valve has a lever mechanism.

- Schedule periodic certification according to local standards (e.g., TCVN) to ensure the valve is always ready to operate.

✅ See also: How to adjust the safety valve

Conclusion

Proper installation of safety valves for boilers, pumps, or water heaters not only ensures efficient equipment operation but also guarantees the safety of users and the entire system. Even a small installation mistake—such as installing the valve backwards or neglecting regular inspections—can lead to serious consequences.

We hope the guidelines in this article have helped you understand the correct way to install safety valves, avoid common errors, and take a proactive approach to operating pressure equipment. If you need further technical advice on installation or assistance in selecting the right safety valve for your system, Bao Tin Steel is always ready to support you.

Bao Tin Steel specialises in supplying steel pipes, various fittings, valves, and fire protection equipment. For quotes or support, call now: 0932 059 176!

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ