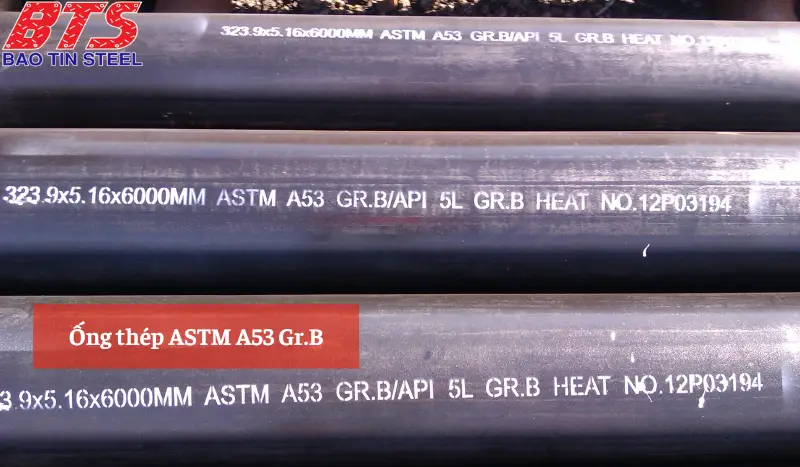

ASTM A53 – Technical standard for welded, seamless black and hot-dip, galvanized steel pipes.

As you can see by the name of the standard, ASTM A53 is both a seamless steel pipe standard and a welded steel pipe standard.

ASTM, whose English trading name is ASTM International, is an international standards organization whose mission is to:

- Carry out the development of technical standards for materials, products, systems, and services.

- Publishes technical standards for a wide range of materials, products, systems, and services.

ASTM A53 is a standard used by many countries around the world. To serve as a basis for evaluating the quality of black, hot-dip steel pipe products.

Let’s learn more about this standard with Bao Tin Steel!

What is ASTM A53?

In short, “ASTM A53 is a carbon steel alloy used as structural steel or for low-pressure plumbing systems. The alloy’s specifications are specified by ASTM International in specification ASTM A53/A53M.”

The ASTM A53 standard is one of the most important standards of the American Society for Materials and Technology (ASTM) for steel pipes subjected to high pressure and temperature. This standard specifies the requirements for the following criteria:

- Material quality

- Size

- Mechanical properties

- Testing of steel pipes.

This specification applies to hot-dip galvanized steel pipes, seamless black steel pipes, and welded at NPS 1/8 to NPS 26.

Steel classified under this standard shall be:

- Open steel

- Basic oxygen or treated by an electric furnace

- Must contain the following: carbon, manganese, phosphorus, sulfur, copper, nickel, chromium, molybdenum, and vanadium.

The pipe must undergo a seamless welding process. Tension, bending, and flattening tests will be performed. To ensure that they comply with the mechanical characteristics of the standard.

The hydrostatic test applied must show no leakage through the weld or pipe body.

Non-destructive electrical testing must be performed. To ensure that the entire volume of the pipeline must comply with the standard.

The buyer shall have the right to make any inspections and tests. To ensure that pipelines comply with regulatory requirements.

Scope of the ASTM A53 standard

Applicable conditions and notes of the ASTM A53 standard

This specification applies to seamless black and hot-dip galvanized steel pipes, welded in NPS 1/8 to NPS 26 [DN 6 to DN 650] (Note 1), inclusive of nominal wall thicknesses (Note 2), as stated in Tables X2.2 and X2.3 of this standard.

It is allowed to equip pipes of other sizes, provided that the pipeline complies with all other requirements of this standard.

Optional additional requirements are given and only apply when specified by the purchaser.

Note 1: NPS (nominal pipe size) dimensionless symbols [DN (nominal diameter)]. have been substituted in this standard for traditional terms such as “nominal diameter,” “dimensions,” and “nominal dimensions.”.

Note 2: The term nominal wall thickness has been assigned for convenience of designation. It exists only in name and is used to distinguish it from the actual pipe wall thickness. It may vary over or under nominal wall thickness.

This technical standard covers the following types and grades:

- Type F — Butt weld, continuous welding Grade A. Has a minimum yield strength of 30000 PSI, and a maximum tensile strength of 48000 PSI.

- Type E — Resistance welding, Grades A and B.

- Type S — Seamless (seamless steel pipe), Class A and B.

For E and S Grade A steel pipes, the minimum yield strength must be 30,000 PSI, and the maximum tensile strength must be 48,000 PSI.

For E and S Grade B steel pipes. The minimum yield strength is 35000 PSI, maximum tensile strength is 40000 PSI.

Note 3: See Appendix X1 for definitions of pipe types.

ASTM A53 Grade A standard

ASTM A53 Grade A is a grade of this standard, with lower thickness and pressure resistance than Grade B.

However, the durability of Grade A steel pipes can be improved by adding alloys such as manganese, copper, nickel, vanadium, or titanium. In addition, the manufacturing process and heat treatment can also affect the durability of Grade A steel pipes.

Therefore, to ensure the quality and durability of Grade A steel pipes, specific technical requirements regarding alloy, thickness, bendability, elongation, hardness, and durability of the material must be followed. maintained, and inspected periodically.

It is used for applications that do not require high durability, such as water, gas, and oil conveying.

ASTM A53 Grade B standard

ASTM A53 Grade B has higher thickness and pressure resistance than Grade A. Therefore, it is often used for applications that require higher durability, such as in the oil and gas industry.

Grade B steel pipes must meet specific quality requirements regarding the alloy, thickness, bend, elongation, hardness, and durability of the material. It must also meet non-destructive testing requirements, such as tensile testing, flexural testing, and elongation testing.

However, the thickness and durability of Grade B steel pipes also depend on the production process and heat treatment. Therefore, to ensure the quality and durability of Grade B steel pipes, specific technical requirements must be complied with and inspected periodically.

Production process and heat treatment of steel pipes in the ASTM A53 standard

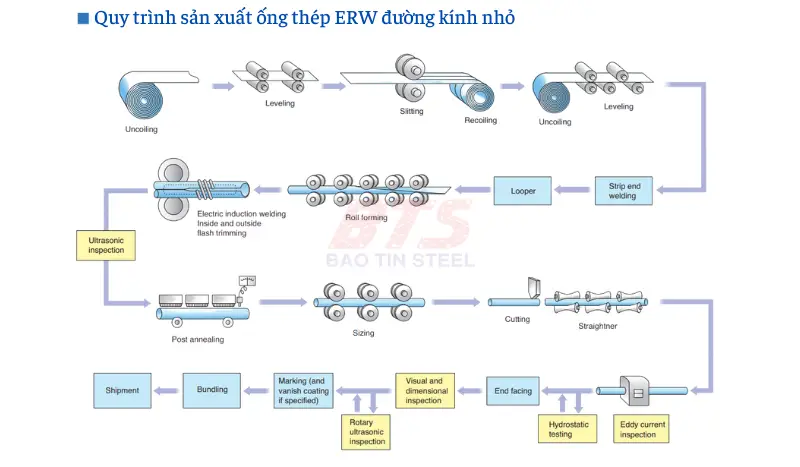

Steel pipe production process

The steel pipe production process in the ASTM A53 standard includes the following steps:

- Material selection. Steel pipes in the ASTM A53 standard are manufactured from carbon steel, containing alloys such as manganese, copper, nickel, vanadium, or titanium to improve the durability of the material. The selected raw material must meet the quality and purity requirements of steel.

- Cut and prepare the ingredients. Raw materials are cut and prepared according to the required size and thickness of the steel pipe.

- Adjust shape. The material is fed into the winding machine and compressed to adjust the shape of the tube. This can be done using a double-, triple-, or quadruple winder to create a rounded shape.

- Weld. The welding process is used to join pieces of steel together and create a weld seam on the surface of the pipe.

- Oil removal and surface treatment. Steel pipes are degreased and surface-treated to remove any grease, rust, or dirt on the surface of the pipe. This helps increase the durability and abrasion resistance of the tube.

- Check quality. Steel pipes will be tested for tensile strength, bending, and elongation. If pipes do not meet specific quality requirements, they are either scrapped or repaired to meet the requirements.

- Packaging and shipping. Steel pipes are packaged and transported to different locations for use in different applications.

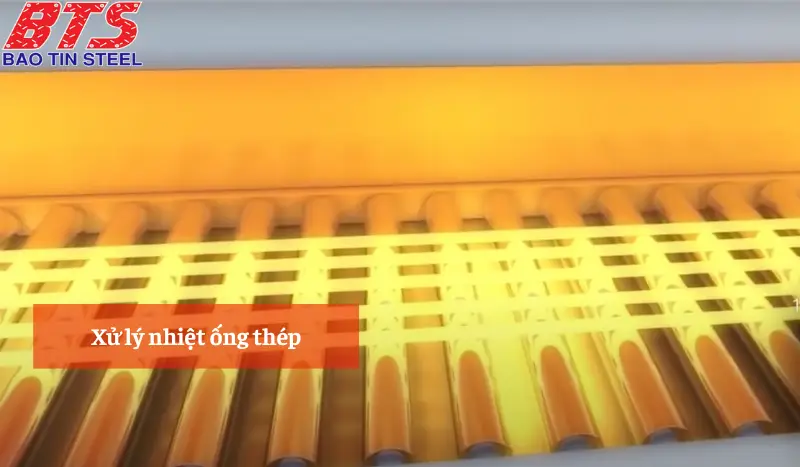

Heat treatment process for steel pipes

Heat treatment is the process of adjusting the crystal structure of steel pipes by increasing or decreasing the temperature of the material. This process creates different mechanical and physical properties in steel pipes.

The heat treatment process in ASTM A53 is performed to increase the mechanical properties of the material. At the same time, ensure that the quality requirements of different applications are met. Proper heat treatment will help increase the durability and abrasion resistance of steel pipes.

The heat treatment process includes the following steps:

- Heat treatment. The steel pipe is inserted into the heater and preheated to a high temperature. To remove impurities and reduce material hardness.

- Uniform heat treatment. The steel pipe is inserted into the heater and kept at a high temperature for a certain time to homogenize the crystal structure of the material throughout the pipe.

- Sublimates and softens. After homogenization, the steel pipe is put into the sublimation furnace to reach the sublimation temperature and is kept there for a certain period to soften the material.

- Cool. After completing the heat treatment process, the steel pipe is taken out of the furnace and cooled naturally or by rapid cooling to avoid deformation or reduction of material properties.

- Check quality. After heat treatment, the steel pipe is quality tested to ensure it meets the requirements of ASTM A53 standards.

Check and evaluate the quality of steel pipes according to ASTM A53 standards.

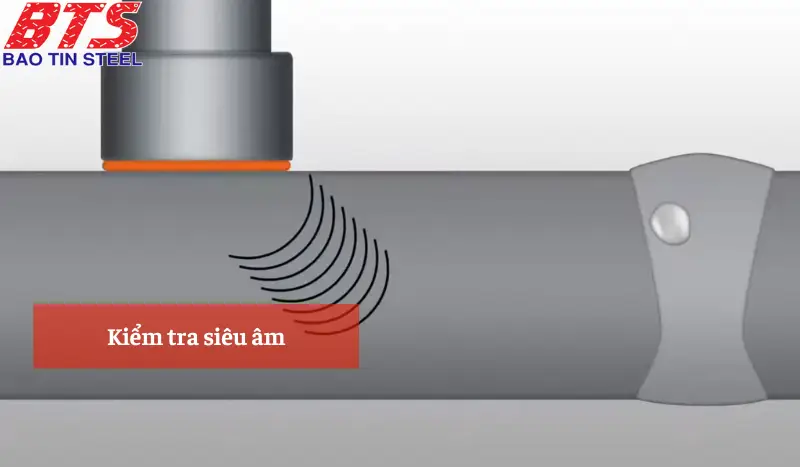

Non-destructive testing of steel pipes in ASTM A53 standard

Non-destructive testing (NDT) is the process of checking the quality of steel pipes according to ASTM A53 standards without causing damage to the material. Non-destructive testing methods include

- Ultrasonic Testing (UT) The UT method uses ultrasonic waves to detect internal defects in steel pipes.

- Magnetic Particle Testing (MPT) The MPT method uses magnetism to detect defects on the surface of steel pipes. People will coat a liquid containing magnetic particles on the surface of the steel pipe and use a magnet to create a magnetic field. If there are defects on the surface, magnetic particles will be concentrated there.

- Eddy Current Testing (ECT). The ECT method uses alternating current to create a magnetic field and detect internal defects in steel pipes. People will insert a coil of wire that generates alternating current into the inside of the steel pipe. Then measure changes in the magnetic field to detect internal defects.

- Radiographic testing (RT). The RT method uses X-rays or gamma rays to detect internal defects in steel pipes. People will insert an X-ray or gamma-ray source inside the steel tube. And use a film to record images of X-rays or gamma rays after they pass through the material.

Non-destructive testing methods are used to ensure that steel pipes are free from voids, cracks, thin cracks, and other impurities.

Chemical testing of steel pipes

Chemical testing of steel pipes in the ASTM A53 standard is the process of determining the chemical composition of the material. The chemical composition of steel pipes specified in the ASTM A53 standard includes:

- Carbon (C): From 0.25% to 0.30%

- Manganese (Mn): From 0.95% to 1.20%

- Phosphorus (P): Maximum 0.05%

- Sulfur (S): Maximum: 0.045%

- Copper (Cu): Maximum 0.40% (if any)

- Nickel (Ni): Maximum 0.40% (if any)

- Chromium (Cr): Maximum 0.40% (if any)

- Molybdenum (Mo): Maximum 0.15% (if any)

The chemical testing process of steel pipes in the ASTM A53 standard includes sampling steel pipes and analyzing the chemical composition of the material in the laboratory. Common chemical analysis methods include:

- Spectroscopic analysis. This method uses optical spectroscopy to determine the chemical composition of steel pipes. This testing process involves exposing a steel pipe sample to a flame to create atoms and ions, and then using spectroscopy to analyze the chemical composition of the material.

- Wet chemical analysis. This method uses chemicals to analyze the chemical composition of steel pipes. This testing process includes putting steel pipe samples into chemical solutions to react and analyze the chemical composition of the material.

Through chemical testing, we can evaluate the quality of steel pipes according to ASTM A53 standards.

Mechanical testing of steel pipes in the ASTM A53 standard

Mechanical testing of steel pipes in the ASTM A53 standard is the process of determining the mechanical properties of materials. Including tensile strength, elongation, hardness, flexural strength, and impact strength. Commonly used mechanical testing methods include the following:

- Tensile Testing. By using a tensile machine to measure the tensile strength of steel pipes and the elongation at break. This testing process involves pulling a steel pipe sample until it breaks to measure the material’s mechanical parameters.

- Hardness Testing. By using a hardness testing machine to measure the hardness of steel pipes. This testing process involves inserting a probe into the surface of the steel pipe and measuring the force there to determine the hardness of the material.

- Bend Testing. By using a bending machine to measure the bending of steel pipes. This testing process involves bending a sample of steel pipe until it breaks to measure the material’s bending strength.

- Impact Testing. By using an impact testing machine to measure the impact strength of steel pipes. This testing process involves applying a beater to a steel pipe sample to measure the impact resistance of the material.

Through mechanical testing, it is possible to evaluate the mechanical properties of materials and ensure that they meet the necessary standards and technical requirements.

Application of steel pipes in the ASTM A53 standard

Steel pipes in ASTM A53 standards are widely used in a variety of applications, including:

- Water and gas pipelines. ASTM A53 steel pipes are used to carry water and gas in water supply and drainage systems, compressed air systems, and other applications.

- Oil and gas pipelines. ASTM A53 pipe is used to carry oil and gas in oil and gas pipeline systems. Including applications in the oil and gas industry.

- Fuel pipelines. ASTM A53 steel pipes are used to carry different types of fuel. Including oil, gasoline, diesel, and biofuels.

- Steam pipeline. ASTM A53 steel pipes are used to conduct steam in steam production and supply systems. Including applications in the food and pharmaceutical industries.

- Fluid and gas pipelines in various industrial applications. Includes applications in the chemical industry, food processing, and metal processing.

With its versatility and durability, steel pipe in ASTM A53 standard is one of the most commonly used materials in various pipeline applications. Especially in industrial and construction applications.

>> Download standard ASTM A53 PDF

It cost Bao Tin Steel an amount of $78 to download this original document file from ASTM.ORG. So if you download it, please give Bao Tin a source note! Thank you :).

Tiger Steel is a branch of Bao Tin Steel

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ