During the construction of piping systems, you’ve probably encountered situations where you need to change the direction of flow, split a branch, or merge two flows into one. Instead of installing multiple complex valves, the 3-way ball valve is a much more compact and efficient solution. This type of valve is commonly chosen by engineers and investors who want to save space, reduce material costs, and ensure ease of operation. Not only is it flexible, but it also helps the system run smoothly, with fewer leaks and easy maintenance.

In this article, we’ll dive deeper into the 3-way ball valve. From its structure, common types of balls, to its working principle, advantages, and practical applications. Let’s check it out!

What is a 3-way ball valve?

A 3-way ball valve (also known as a 3-port valve or 3-way valve) is a type of ball valve with three connecting ports (one inlet and two outlets, or vice versa—two inlets and one outlet). It allows for changing the direction of flow, mixing, or splitting the fluid with just a single device.

A 3-way ball valve can direct the flow to different branches, mix two streams of liquid/gas into a single flow, or split one flow into two separate branches.

Structure of a 3-way ball valve

Understanding the structure will help you choose the right type of valve for your system. Below are the important components that make up a 3-way ball valve:

-

Valve Body: This is the outer shell of the valve, specially designed with three connecting ports. Depending on the working environment and type of fluid, the valve body can be made from stainless steel, cast iron, steel, or plastics like PVC, UPVC, PPH, or HDPE. Each material is suited for different applications (clean water, chemicals, wastewater, etc.).

-

Ball (Ball Disc): This is the most important component inside the valve. The ball is spherical and has an L-shaped or T-shaped hole, which helps to direct the flow as desired: splitting branches, mixing flows, or changing the flow direction.

-

Valve Stem: The stem connects the ball to the handle or actuator. When the stem rotates, the ball rotates with it, thus changing the direction of the flow inside the valve.

-

Seals (Stem Seal & Ball Seal): These seals are usually made from PTFE (Teflon), EPDM, or Viton and serve to ensure the valve does not leak during operation, even when working with high pressure or corrosive fluids.

-

Control Mechanism: This can be a manual handle for operation or an automatic control system, like electric or pneumatic actuators. Depending on the system requirements, the valve can operate in a simple ON/OFF mode or regulate flow according to the opening angle.

Operating Principle of a 3-Way Ball Valve

The 3-way ball valve operates based on the principle of rotating the ball to change the flow direction. Inside the valve is a hollow ball with a hole cut in either an L or T shape. When the user turns the handle or activates an automatic actuator (electric or pneumatic), the valve stem transmits rotational force to the ball. This causes the ball to rotate around its axis.

Depending on the rotation angle and the type of ball (L or T), the flow of fluid will be directed in different ways:

-

Change the flow direction from one port to another.

-

Mix two streams of fluid into one.

-

Split one flow into two directions simultaneously.

-

Block any of the three ports.

The valve can operate in 2 modes:

-

ON/OFF: The valve has only two states: fully open or fully closed, depending on the flow direction (commonly used in pneumatic or simple electric control valves).

-

Flow regulation by opening angle: For systems that require precise flow control, the valve can be partially opened or the rotation angle can be adjusted to achieve the desired flow rate (commonly used in linear control valves).

Common Types of 3-Way Ball Valves Nowadays

If you are just starting to learn about 3-way ball valves, it can be a bit confusing as there are many different types available on the market: L-type, T-type, handle-operated, pneumatic, electric, etc. So, what’s the difference between each type? Below are a few ways to classify these ball valves:

Classification by Ball Shape: L-Type and T-Type

This is the most important classification. The shape of the ball’s hole determines how the flow passes through the valve.

-

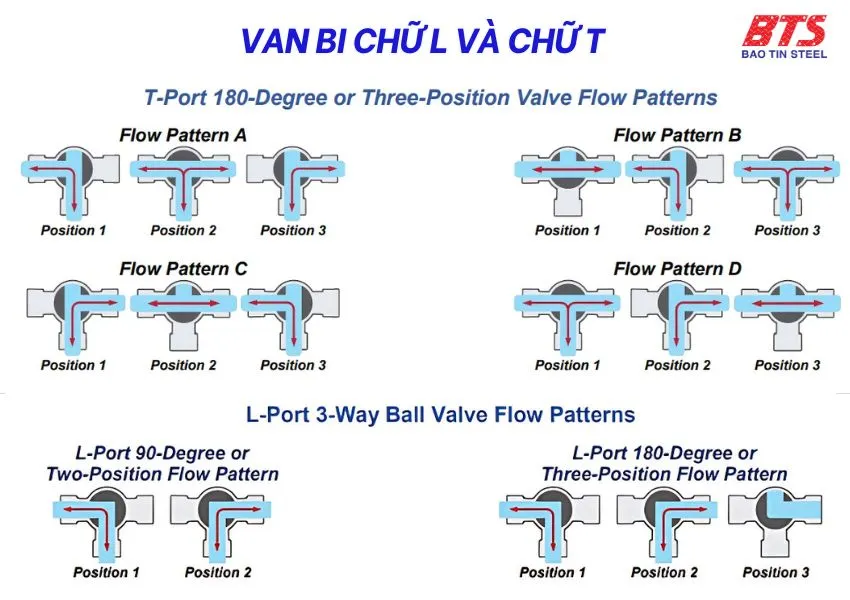

L-Port 3-Way Ball Valve: The ball has an L-shaped hole. It allows the flow to be redirected from one port to another (e.g., from port A to B, or A to C). This type does not allow simultaneous connection of all three ports. It is suitable when you want to control the flow between two separate branches.

-

T-Port 3-Way Ball Valve: The ball has a T-shaped hole, allowing the flow to mix from two sources or split into two directions at the same time. The T-port is more flexible, as it can connect all three ports simultaneously or close one port depending on the valve’s rotation. It works well when you need to both split and mix the fluid flow.

Classification by Control Method

Depending on whether the system is simple or highly automated, you can choose from the following:

-

Manual Lever Operated 3-Way Ball Valve: Manually operated by rotating the lever. Easy to use, cost-effective, and suitable for small systems or when remote control is not necessary.

-

Pneumatically Controlled 3-Way Ball Valve: Uses a pneumatic actuator to automatically open/close the valve. Provides fast response and is ideal for factories or industrial production lines.

-

Electrically Controlled 3-Way Ball Valve: Uses an electric motor to control the valve. It can be integrated with a central control system (PLC). Suitable for systems that require high levels of automation.

Classification by Material

Depending on the working environment (temperature, pressure, type of fluid), you should choose the appropriate valve material:

-

Stainless Steel (SUS304, SUS316): Durable, highly corrosion-resistant, used for clean water, food, and chemical applications.

-

Cast Iron: Cost-effective, good load-bearing capacity, suitable for potable water systems or wastewater treatment.

-

Brass: Lightweight, good thermal conductivity, reasonably priced. Particularly resistant to rust in clean water environments, but not suitable for highly corrosive fluids such as acids or alkalis.

-

Plastic (PVC, UPVC, PPH, HDPE): Lightweight, highly corrosion-resistant, used for diluted chemicals, irrigation systems, or low-pressure environments.

Classification by Connection Type

The connection type affects the installation and the ability to disassemble the valve when maintenance is required:

-

Threaded Connection: Common in smaller pipes, easy to install, and convenient for replacement.

-

Flanged Connection: Secure, used in large industrial systems, and easy to maintain.

-

Welded Connection: Absolutely leak-tight, but fixed and non-removable, used in high-pressure systems.

Applications of 3-Way Ball Valves

Outstanding Advantages

A single valve replaces multiple 2-way valves, helping to reduce the number of devices and accessories required.

-

Compact design with fewer connection points, saving both space and installation costs.

-

Can redirect, split, or mix flows flexibly with just one device.

-

Prevents leaks effectively, just like conventional ball valves.

-

Especially effective when combined with automatic control systems (pneumatic/electric).

Common Applications

In Industry

-

Water Supply/Drainage Systems: The valve is used to control the flow of water in factories and industrial areas, making it easier to manage the flow to different zones.

-

Gas, Steam, and Chemical Processing: The 3-way ball valve is very effective in directing compressed air, steam, liquid chemicals, or solvents in production lines.

-

Production Lines: It is used when there is a need to split the product flow into multiple directions or mix different components into a mainstream. For example, in the food, cosmetics, or raw material processing industries.

In Household Applications

-

Automatic Irrigation Systems: Allows for splitting the water flow to different garden areas or switching the flow to secondary water sources.

-

Hot/Cold Water Systems: The valve helps mix or redirect water flow in heating systems, especially in buildings with central heating systems.

-

Fish Tanks, Water Filtration, Swimming Pools: Assists in directing water into/out of storage tanks, for filtration or wastewater discharge, making it very convenient and easy to operate.

👉👉Check out a few other types of valves at Bao Tin Steel:

Conclusion

The 3-way ball valve is a smart choice for systems that require flow splitting, mixing, or controlling multiple directions of fluid within a single device. With its flexible design, simple operation, and space-saving features, the 3-way ball valve is increasingly popular in both industrial and household applications.

If you need advice or are looking to purchase high-quality 3-way ball valves, Bao Tin Steel is a trusted choice. We offer a wide range of stainless steel, cast iron, and plastic ball valves with full CO-CQ documentation and dedicated technical support. Contact us now for expert advice and fast delivery! 👉👉 Call now – Hotline: 0932 059 176.

Tiger Steel is a subsidiary of Bao Tin Steel.

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ