You know, the size of a steel pipe (whether a cast steel pipe or a welded steel pipe) depends a lot on the SCH index and the material from which it is made.

With the same SCH index, each pipe diameter has a different nominal size. And we have already learned what SCH is from the previous article.

So what is the nominal size? What are the steel pipe standards? Please read down to the next part!

What are steel pipe standards?

Steel pipe standards are documents that stipulate the technical requirements, quality, dimensions, structure, production standards, inspection, and quality assurance of steel pipes. Steel pipe standards are specified to ensure uniformity in the production, supply, and use of steel pipes in different applications and to make the comparison and selection of steel pipes easier.

International, national, or industry organizations develop steel pipe standards, for example, ASTM, API, JIS, DIN, BS, GOST, etc.

➡️See more: Seamless steel pipe standards.

Introduction to the SCH 40 seamless steel pipe standard

SCH40 stands for Schedule 40, which is one of the types of pipe schedules used to determine the thickness and diameter of seamless steel pipes.

According to this standard, SCH40 seamless steel pipes have a wall thickness of about 3.68mm and are produced in different diameter sizes. In addition, the SCH40 seamless steel pipe standard also specifies the requirements for chemical composition, durability, and elongation of SCH40 seamless steel pipes.

The SCH40 seamless steel pipe standard is widely used in the following applications:

- Building

- Road and bridge projects

- Installation of water and gas pipes, etc.

The advantages of SCH40 seamless steel pipes are the ability to withstand high pressure, good durability and elongation, and the price is also quite reasonable.

However, users need to pay attention to other factors such as usage environment, temperature, and pressure to choose the most suitable type of seamless steel pipe for their application.

In addition to the SCH40 standard, there are many other standards such as Sch10, Sch20, Sch30, Sch60, Sch80, Sch120, Sch160, and SchXXS, depending on the size and thickness requirements of the steel pipe.

Nominal sizes of steel pipes: definitions and symbols

Certainly when you look at any steel pipe manufacturer’s catalog. You will also see the presence of two components, which are:

- Nominal size (NPS), the unit system is an inch.

- Nominal diameter (DN): the unit system is mm.

See also: Seamless steel pipe symbols

Have you ever wondered why you have to have both of these sizes?

This comes from the actual needs of users. Because construction businesses are not just Asian businesses. But there are also Western businesses. So we have to put both together so that any customer can use them and look them up easily.

- Nominal Size (NPS) is a dimensionless pipe size designator according to North American standards. For pipes used for high or low pressure and temperature. It indicates the standard size of steel pipes in inches. The NPS designation is based on the previous “Iron Pipe Dimensions” (IPS) system.

- To internationalize pipe sizes, the International Standards Organization (ISO) also uses a system with a dimensionless designation called nominal diameter (DN). The DN symbol indicates a standard pipe size when followed by a number designating the specific size without the mm symbol. This definition is stated very clearly in the ISO 6708 standard.

Nominal diameter (DN) applies to all plumbing, natural gas, oil, and other piping used in buildings.

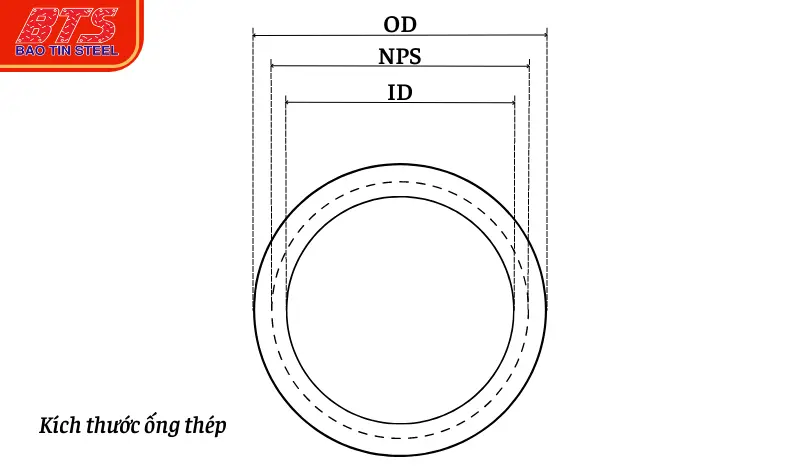

For a given NPS, the outside diameter (OD) of the steel pipe is constant. While the tube wall thickness increases with a larger SCH number, The inside diameter (ID) will depend on the pipe wall thickness indicated by the SCH number..

SCH40 seamless steel pipe standard and SCH index

As you can see, just the nominal size index is enough to determine the steel pipe diameter. However, calculating and choosing suitable steel pipes for the project’s needs requires more information than that.

That is the reason for the appearance of the SCH index.

The SCH index of steel pipes is the standard for the thickness of the steel pipe wall. This index directly affects the inner diameter and weight of each pipe. At the same time, the SCH index is also very important in determining the working pressure level of steel pipes.

You can see the formulas for calculating steel pipe pressure to better understand this relationship.

The SCH index is the result of the following approximation:

Sch = 1000 P/S

In there:

- P is the internal usage pressure of the pipeline (psig).

- S is the ultimate tensile strength of the pipe material (psi).

The higher the SCH number, the thicker the steel pipe.

Among the SCH indices, the two most common indices found in most buildings are SCH40 and SCH80. However, it depends on the flow rate in the pipeline and the working pressure requirements. Buildings, utilities, etc. may require different SCH indexes.

Technical parameters of standard seamless steel pipe (SCH40)

Dimensions of cast steel pipe SCH 40

Facts you should know:

- The numbers SCH40 and 80 are nearly as valuable as STD and XS, and in many cases, they are equal in value.

- From NPS 12 and above, the wall thickness between SCH 40 and STD is different. From NPS 10 and above, the wall thickness between SCH 80 and XS is different.

Chemical composition of SCH 40 seamless steel pipes

The chemical composition of SCH40 seamless steel pipes is specified in various standards and norms. Depending on the regulations of the manufacturing organization and country, However, usually, the chemical composition of SCH40 seamless steel pipes includes the following main components:

- Carbon (C): This is the main ingredient that makes up SCH40 seamless steel pipes. Can account for 0.3% to 0.5% of the weight of seamless steel pipes.

- Manganese (Mn): This ingredient helps increase the toughness and hardness of cast steel pipes. Usually, rates range from 0.6% to 1.65%.

- Silicon (Si): This ingredient helps increase the corrosion resistance of cast steel pipes. It usually ranges from 0.25% to 0.6%.

- Phosphorus (P) and sulfur (S): This ingredient helps form the crystal structure of cast steel pipes. There are usually low ratios, around 0.05% for each ingredient.

- Iron (Fe): Is the main component of seamless steel pipes, with a ratio of 98.5% to 99.2%.

Controlling and preserving the chemical composition of SCH40 seamless steel pipes is very important to ensure product quality. Manufacturers often use quality testing and control methods. To ensure chemical ingredients comply with regulations and ensure product uniformity.

Mechanical properties of SCH 40 seamless steel pipes

The mechanical properties of SCH40 seamless steel pipes ensure good bearing capacity, high durability, and good elongation. At the same time, it also demonstrates the stable and uniform mechanical properties of the product. However, to ensure safe and effective use, Users need to choose SCH40 seamless steel pipes that suit their technical requirements and applications.

Below is some information about the mechanical properties of SCH 40 seamless steel pipes:

- Tensile. The tensile strength of SCH 40 seamless steel pipe is about 414 MPa (megapascal). This is the index that evaluates the top tensile force resistance of SCH 40 seamless steel pipes.

- Elongation. The elongation of SCH 40 seamless steel pipe is about 25%. This is an index to evaluate the ability of SCH40 seamless steel pipes to withstand deformation when stretched.

- Stiffness. The hardness of SCH40 seamless steel pipes is measured by measuring Brinell hardness (HB) or Rockwell hardness (HR). The hardness of SCH40 seamless steel pipes is usually in the range of 80 to 90 HB or 70 to 80 HR.

- Impact resistance. The impact resistance of SCH40 seamless steel pipes depends on many factors. Including tube thickness, impact speed, and impact direction. The impact strength of SCH40 seamless steel pipes is usually in the range of 50 to 60 Joules.

Application of SCH 40 seamless steel pipe

SCH40 seamless steel pipe is an important material in many different applications, ensuring safety and stability during use. At the same time, it also meets the technical requirements and quality standards of the manufacturing industry.

Below are some typical applications of SCH 40 seamless steel pipes:

- Construct. SCH40 seamless steel pipes are used in the construction of bridges and roads, factories, warehouses, buildings, etc. SCH40 seamless steel pipes ensure stable mechanical properties, high durability, and good bearing capacity, helping to increase safety. safety and stability of the project.

- Install water and gas pipes. SCH 40 seamless steel pipes are used to install water, gas, and drainage systems in construction projects.

- Manufacture of equipment and machinery. SCH40 seamless steel pipes are also used to produce equipment and machinery in many different industries, such as automobile manufacturing, industrial machinery, agricultural machinery, etc.

- Production of oil and gas pipelines. SCH 40 seamless steel pipes are also used to produce oil and gas pipelines. Ensuring safety and stability during oil and gas transportation and storage.

- Manufacturer of refrigeration system equipment. SCH 40 seamless steel pipes are also used to produce refrigeration system equipment in construction projects.

Compare the SCH 40 seamless steel pipe standard with the SCH 80 seamless steel pipe standard

SCH40 and SCH80 seamless steel pipe standards are both important standards in the seamless steel pipe manufacturing industry. However, there are differences between these two standards, as follows:

- Pipe thickness. The thickness of SCH80 seamless steel pipe is higher than that of SCH40 seamless steel pipe. Therefore, SCH80 seamless steel pipes have a higher bearing capacity and are used in applications that require higher safety.

- Pressure withstand. SCH 80 seamless steel pipes can withstand higher pressure than SCH 40 seamless steel pipes.

- Price. The price of SCH 80 seamless steel pipes is often higher than SCH 40 seamless steel pipes due to their thickness and higher bearing capacity.

- Use. SCH40 seamless steel pipes are often used in the construction and installation of water and gas pipeline systems, etc. Meanwhile, SCH80 seamless steel pipes are often used in applications that require higher safety, especially in oil and gas pipeline systems.

However, SCH40 and SCH80 seamless steel pipes both have their advantages and limitations and are used in different applications. When choosing the appropriate type of seamless steel pipe, users should consider technical requirements, bearing capacity, safety, and cost to ensure the correct and effective choice.

Address for selling reputable and quality SCH 40 welded pipes in Ho Chi Minh City

Bao Tin Steel Company Limited is one of the reputable, quality, and good-priced SCH40 seamless steel pipe suppliers. Here, Bao Tin provides SCH40 seamless pipes according to ASTM A53/A106/API 5L standards, etc., in diverse sizes.

Besides distributing SCH40 seamless pipes, Bao Tin Steel also supplies SCH10, SCH20, SCH30, SCH80, etc.

To meet customer needs to the maximum, we also offer many other products:

- Flange Large diameter steel pipe

- Steel Steel plate

- Elbow 90 / Elbow 45

- Coupling

- Concentric reducer – eccentric reducer,…

In short, if you are interested and want to buy the product but are still wondering where to buy it, Bao Tin Steel is a suggestion for you. Please contact us so our sales staff can advise and send the most accurate quote.

Video introducing Bao Tin Steel products

So we have learned about the SCH40 molded pipe standard. Bao Tin Steel hopes that through this article, you will have an overview of SCH40 seamless pipes as well as find a reputable and quality supplier.

Tiger Steel is a branch of Bao Tin Steel.

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ