In a boiler system, without a safety valve, just one instance of overpressure could cause the entire boiler to explode, resulting in damage worth hundreds of millions of VND. In a compressed air pipeline, if pressure isn’t released in time, the excess pressure can destroy all downstream equipment. In hydraulic systems, a sudden pressure surge can easily crack pipes, cause oil leaks, and disrupt production. That’s why safety valves are often considered the “lifesaving valves” of any system.

In this article, Bao Tin Steel will walk you through an overview of safety valves—from what a safety valve is, how pressure relief works, and applications across different media (water, air, steam, hydraulic fluid, gas), to proper installation guidelines and a detailed pricing table. If you’re looking to optimise performance and ensure safety in your system, this is essential information you won’t want to miss.

What is a Safety Valve?

A safety valve is a device designed to release excess pressure from a system when it exceeds a predetermined limit, in order to protect equipment, pipelines, and personnel from explosions, leaks, or mechanical failures.

The valve is typically installed at the highest point of pressure-bearing equipment such as boilers, storage tanks, compressed air lines, or hydraulic systems. It serves as the last line of defence, automatically releasing pressure when all other pressure control devices fail to maintain safe levels.

Whether it’s a small-scale system like a household water heater or a large-scale industrial plant like a thermal power station, safety valves are mandatory components to ensure safe, stable, and uninterrupted operation.

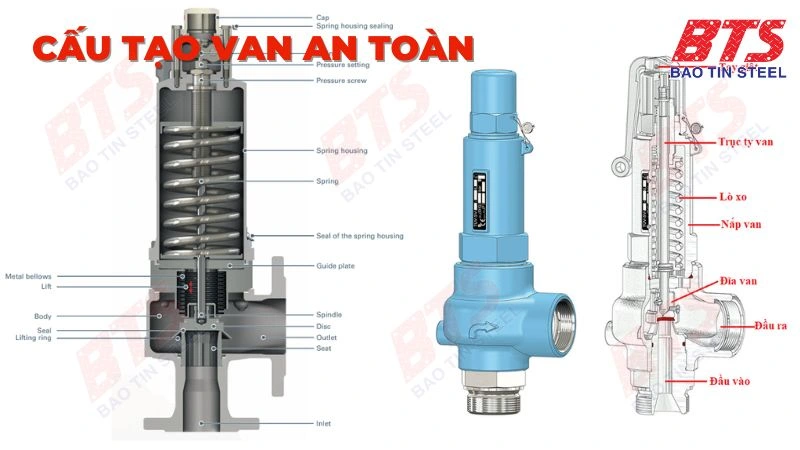

Structure of a Safety Valve

Basic Structure of a Safety Valve

Although safety valves come in various shapes, materials, and colours, they generally share the same basic components. The key parts of a safety valve include:

- Body

The main casing of the valve, typically made from corrosion- and pressure-resistant materials such as stainless steel, cast iron, carbon steel, or brass.

In indirect (pilot-operated) safety valves, the adjustment knob may be located on the bonnet rather than on the body, as seen in direct-acting types. - Seat (Seal/Gasket)

Forms the sealing surface to prevent leakage when the valve is closed. Usually made of PTFE, Teflon, or other high-performance sealing materials that can withstand elevated temperatures and pressures. - Disc

The movable part that lifts to release pressure when system pressure exceeds the set point.

In pilot-operated valves, the disc is often replaced with a piston to achieve more precise control. - Spring

Provides the closing force on the disc. It keeps the valve shut under normal operating conditions and controls the set pressure at which the valve opens.

In pilot-operated designs, there are often two springs: - A main spring

- A secondary (adjustment) spring, which helps fine-tune the response to slight overpressure situations.

- Spindle (Stem)

Positioned inside the spring, it helps guide the disc along the correct vertical axis during movement.

In designs using a piston instead of a spindle, the valve body itself directs the piston’s movement. - Pressure Adjustment Screw

Allows the user to adjust spring tension, thereby setting the valve’s opening pressure. - Manual Lever (Optional)

Some safety valves are equipped with a manual lever for testing or emergency relief, allowing pressure to be released even before the set limit is reached.

Note: Not all safety valves include this feature.

Operating Principle of a Safety Valve

A safety valve acts as an automatic “emergency release mechanism” for pressurized systems. It operates based on Bernoulli’s principle.

When the pressure inside a pipe or equipment exceeds the allowable limit, the valve automatically opens to release the excess pressure. This action helps protect the entire system from the risk of overload, equipment failure, or even explosion.

The Operating Mechanism Mainly Relies on Two Key Components:

- Spring:

Pre-set with a compression force corresponding to the allowable pressure. When the system pressure is below this force, the spring keeps the valve firmly closed. - Disc (or Piston):

This is the part that directly contacts the medium. When the pressure exceeds the set limit, the force exerted by the fluid overcomes the spring force, pushing the disc upwards and opening the valve to relieve the excess pressure.

Pressure Relief Mechanism

When the valve opens, the excess medium in the system (water, gas, steam, etc.) is released through the discharge outlet. This helps to rapidly reduce the internal pressure back to a safe level.

Once the pressure drops below the preset threshold, the spring automatically pushes the disc back to its original position, closing the valve and preventing any further release of the medium.

What’s special about this process is that it operates fully automatically, requiring no electricity and no remote control. This makes it both convenient and safe to use.

Practical Applications of Safety Valves

Today, safety valves are widely used across many industries—from manufacturing and processing to energy production and everyday household systems. Below are some typical systems that utilise safety valves:

- Industrial Boiler Systems:

Help promptly release pressure when steam pressure exceeds the limit, thereby protecting operators and equipment. - Compressed Air and Gas Pipelines:

Prevent gas leaks, explosions, or damage to shut-off valves by safely relieving excess pressure. - Hydraulic Systems and Compressors:

Release excess oil pressure when the system is overloaded, reducing stress on cylinders, pumps, and control valves to prevent leaks or pipe ruptures. - Hot Water Tanks, Steam Cookers, and Pressure Cookers:

Release pressure when water temperature rises too high, preventing burns, tank explosions, or hot water leaks.

Proper Installation Guide for Safety Valves

To ensure that a safety valve operates accurately, durably, and effectively relieves pressure, proper installation is critically important. Below is a detailed step-by-step guide to help you confidently integrate the valve into your system.

Pre-Installation Requirements:

- Identify the Correct Installation Location:

Safety valves are usually installed at the highest point of the equipment or pipeline. This is where pressure tends to accumulate most, such as on boilers, tank tops, or the discharge end of air compressors. - Clean the Pipeline Thoroughly:

Before installing the valve, clean the pipeline and contact surfaces to prevent dirt or foreign objects from entering the valve, which could cause jamming or leakage. - Check the Flow Direction:

The valve body always has an arrow indicating the flow direction. Make sure to install the valve in the correct orientation so it operates properly when pressure rises.

Steps to Install a Safety Valve

- Choose the Appropriate Connection Type:

Depending on the equipment and pipeline, you can select threaded connections (for small sizes), flanged connections (for large industrial systems), or clamp connections (commonly used in food and pharmaceutical industries). - Tighten Bolts or Couplings Evenly:

For flanged valves, tighten the bolts evenly in a cross pattern, applying the specified torque to ensure a tight seal and avoid flange distortion. - Check for Leaks:

After installation, inspect the joints using soapy water or leak detection equipment to ensure there are no air or water leaks. - Attach a Discharge Pipe (if necessary):

In many systems, it is advisable to install a discharge pipe to safely direct the released medium away from people and sensitive areas, preventing hazards or environmental contamination.

Post-Installation Notes

- Check Pressure Relief Function Manually:

For valves equipped with a manual lever, verify that the lever operates smoothly. The manual lever is used for periodic testing and emergency pressure release when necessary. - Record the Set Pressure:

Note the valve’s opening pressure as a reference for future maintenance checks. - Schedule Regular Inspections:

Safety valves must be inspected and calibrated periodically in accordance with regulatory requirements, especially in high-pressure, steam, or gas systems.

Classification of Safety Valves Based on Medium

Depending on the properties and technical requirements of each medium, safety valves are designed with different structures and materials to ensure accurate, safe, and durable operation. Below are the common types of safety valves classified according to the medium they are used for:

Water Safety Valve

This type of valve is typically made from brass, brass alloys, or stainless steel to resist corrosion. It is commonly used in hot water systems, water supply networks, and residential as well as industrial water heaters. The valve functions to release excess pressure when water pressure exceeds safe limits, such as due to temperature-induced expansion or system malfunctions.

Air Safety Valve

Designed to handle compressed air and gases, these valves are generally constructed from brass, stainless steel, or other corrosion-resistant materials capable of withstanding extreme temperatures. They are intended to release compressed gases, inert gases (argon, nitrogen, helium, CO₂), and flammable gases (propane, methane, natural gas) from systems. This prevents excessive pressure buildup in gas cylinders, compressed air pipelines, or gas-utilising systems.

Steam Safety Valve

Typically made from stainless steel or heat- and pressure-resistant alloys, steam safety valves are specialised for steam systems, boilers, and steam pipelines. They release steam when pressure exceeds the permissible limit, thereby preventing explosions or equipment damage.

Hydraulic Pressure Relief Valve

Hydraulic safety valves are fabricated from high-strength alloy steel designed to withstand high pressures. Used in hydraulic systems where liquids (usually hydraulic oil) transmit force, these valves primarily regulate and control system pressure to protect pumps, cylinders, and other components from damage due to overpressure. When pressure surpasses the set point, the valve opens to redirect fluid back to the reservoir or return line.

LPG/Natural Gas Safety Valve

Similar to air safety valves, these valves are specifically designed for flammable gases such as LPG (liquefied petroleum gas) and natural gas. They prevent hazardous pressure buildup in gas tanks, pipelines, or gas-operated equipment, thereby reducing risks of leaks, fires, or explosions.

Given the specific characteristics of gas media, LPG/natural gas safety valves are manufactured from materials that are non-reactive with the gas and possess flame-retardant properties, ensuring system stability and operational safety.

Additional Classification

Beyond medium-based classification, safety valves can also be categorised by construction materials (brass, cast iron, stainless steel, steel) or by operating mechanisms (with or without a manual lever). However, classification by medium remains one of the most common and practical methods for selecting the appropriate valve for specific applications.

👉👉 Please refer to some products at Bao Tin Steel:

Reference Price List for Safety Valves

Below is a reference price list for various types of safety valves. Please note that the prices listed are indicative and may vary depending on the time of purchase. Factors such as valve size, brand, origin, and order quantity can also affect the final price.

| Safety Valve Size | TungLung with Lever (Taiwan) | China (Threaded, with Lever) |

|---|---|---|

| DN15 | 650,000 VND | 350,000 VND |

| DN20 | 650,000 VND | 450,000 VND |

| DN25 | 830,000 VND | 550,000 VND |

| DN32 | 1,300,000 VND | 600,000 VND |

| DN40 | 1,500,000 VND | 820,000 VND |

| DN50 | 2,400,000 VND | 900,000 VND |

Conclusion

The safety valve is a small but extremely important device in technical systems. Thanks to its ability to automatically release pressure when it exceeds the set limit, the valve helps protect equipment, ensure user safety, and maintain stable system operation.

To ensure effective valve performance, it is essential to select the correct type based on the medium (water, air, steam, hydraulic fluid, or gas). At the same time, proper installation and regular maintenance checks are necessary. Only then can your system be durable and operate long-term.

Bao Tin Steel hopes you now understand what a safety valve is. We are currently a trusted importer and distributor of various materials, including steel pipes, steel tubes, structural steel, piping accessories, industrial valves, and fire protection equipment. If you need further information or product quotations, don’t hesitate to contact us immediately! Hotline: 0932 059 176.

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ