Two-Piece Stainless Steel Ball Valve vs. Three-Piece Stainless Steel Ball Valve

The two-piece stainless steel ball valve is one of the most popular valve types today. It is favoured in many industrial systems with its fast opening and closing ability, high sealing performance, and superior durability. On the other hand, the three-piece stainless steel ball valve is also a valuable option when flexible maintenance and operation in harsher environments are required.

On the market, these two valve types are often compared, especially when users need to choose the appropriate equipment for fluid, gas, or steam transportation systems. So, which type should you choose to optimise both cost and efficiency?

In this article, we will help you compare the two-piece and three-piece stainless steel ball valves. From their structure and technical specifications to their advantages, disadvantages, and practical applications, this guide will make it easier for you to make the best decision based on your specific needs and operating conditions.

What is a Two-Piece Stainless Steel Ball Valve?

A two-piece stainless steel ball valve is a type of ball valve that consists of two main body parts. These parts are connected by bolts or threads, and typically feature a sealing gasket in between to ensure a tight seal. The entire valve is made of stainless steel (usually stainless steel 304 or 316), which helps resist corrosion and makes it suitable for use in various environments such as water, chemicals, gases, and oils.

The distinctive feature of a two-piece stainless steel ball valve is that it has fewer joints compared to the three-piece type. This results in a more compact design, lower production costs, and easier installation. However, maintenance or replacement of internal components, such as the ball or seat, can be more difficult. This is because the entire valve needs to be removed from the piping system.

Detailed Comparison Between Two-Piece and Three-Piece Stainless Steel Ball Valves

When choosing a stainless steel ball valve for a piping system, many people are torn between the two-piece and three-piece stainless steel ball valves. Both have their advantages, but to make the right choice, it’s important to understand the differences in design, maintenance capability, durability, applications, and cost.

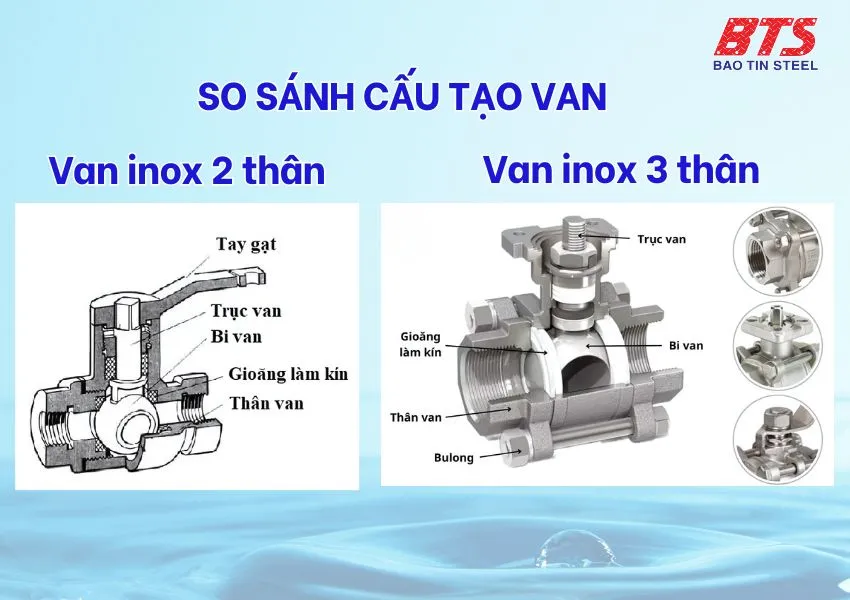

Structure and Design

The Two-Piece Stainless Steel Ball Valve consists of two main parts: the valve body and the valve cover, which are connected by threaded rings or bolts. This design makes the valve compact, with fewer joints, giving it a more solid structure, especially in stable working environments.

The Three-Piece Stainless Steel Ball Valve consists of three separate parts: the central body and two end caps, connected by a bolt system. This design allows the valve to be disassembled into individual parts without affecting the entire system, making it very convenient for maintenance.

Maintenance and Repair Capability

For a two-piece valve, if you need to replace internal components such as the ball or sealing gasket, you typically have to remove the entire valve from the piping system. This process can be time-consuming and labour-intensive, especially in systems that are actively running.

On the other hand, the three-piece valve allows you to detach the middle part of the valve body while keeping the two end connections intact on the piping. This is extremely convenient if you need to clean or replace internal components without shutting down the entire system.

Durability and Sealing Ability

Both types of valves offer good sealing ability if they are manufactured according to the right standards. However:

- The three-piece stainless steel ball valve is often rated higher for its stability when working in harsh environments such as high pressure, high temperatures, or corrosive chemicals.

- The two-piece valve, on the other hand, is suitable for systems that operate under stable conditions and do not require extreme working conditions.

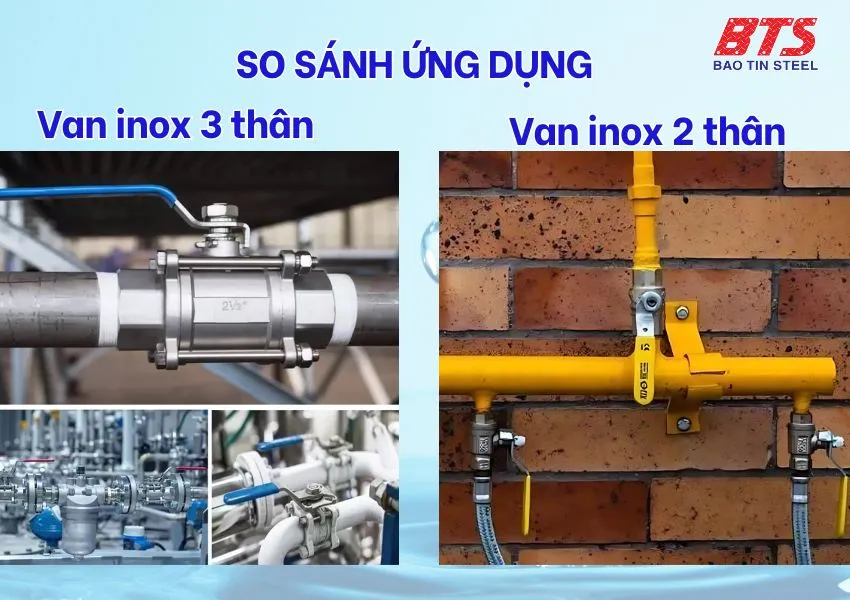

Practical Applications

The two-piece stainless steel ball valve is commonly used in clean water systems, compressed air systems, and low-pressure steam systems. These are environments that do not require frequent maintenance. This type of valve is also a reasonable choice for residential projects or factories with limited budgets.

The three-piece stainless steel ball valve, on the other hand, is more suitable for heavy industrial environments. It is ideal for continuous operations, such as chemical transport systems, hot oil pipelines, or high-pressure compressed air systems. In addition to its good load-bearing capacity, the ease of maintenance is a significant advantage in systems that require flexibility.

Price

The two-piece stainless steel ball valve has a simpler structure, making it more affordable. This helps save on initial investment costs.

In contrast, the three-piece valve, due to its more complex structure and better maintenance capabilities, comes at a higher price. However, it offers long-term cost optimisation, especially if the system requires frequent maintenance.

👉 See more two-piece ball valves available at Bao Tin Steel

Should You Choose a Two-Piece or Three-Piece Stainless Steel Ball Valve?

After understanding the differences between the two types of valves, the question arises: should you choose a two-piece or three-piece stainless steel ball valve for your system? Below are some criteria to help you make a more accurate decision.

Selection Criteria

To choose the right type of valve, you should consider the following factors:

-

Working Environment: If the system operates under high pressure, high temperatures, or contains chemicals, it’s advisable to prioritise a valve with better load-bearing capacity and corrosion resistance, such as the three-piece valve.

-

Frequency of Use: If the system operates continuously and requires regular maintenance, the three-piece valve will be more convenient due to its flexible disassembly capability. On the other hand, if the system runs infrequently or requires minimal maintenance, the two-piece valve is perfectly adequate.

-

Investment and Maintenance Costs: The two-piece stainless steel ball valve is more affordable, saving on initial investment. While the three-piece valve has a higher upfront cost, it optimises long-term maintenance costs if the system requires frequent servicing.

Each type of valve has its characteristics and advantages. Therefore, it’s important to understand your project and compare it with the criteria above to select the most suitable valve!

Suggested Applications by Type

When to Use a Two-Piece Stainless Steel Ball Valve?

-

Clean water systems, compressed air systems, and low-pressure steam systems.

-

Residential projects, small workshops, or places that do not require frequent maintenance.

-

Projects with limited investment budgets but still requiring basic operational efficiency.

When to Use a Three-Piece Stainless Steel Ball Valve?

-

Chemical transport systems, hot oil pipelines, steam systems, or environments with high corrosion levels.

-

Industrial factories operate continuously, requiring regular maintenance without the need to remove the entire valve.

-

When high sealing performance, pressure resistance, durability, and operational flexibility are required.

Whether it’s a two-piece or three-piece stainless steel ball valve, each type has its advantages suited to specific operating conditions. Choosing the right valve not only helps the system operate efficiently and stably but also optimises both investment and long-term maintenance costs.

We hope the information in this article has provided you with a clearer understanding to choose the most suitable stainless steel ball valve for your needs. If you need further advice or are looking for a reliable industrial valve supplier, don’t hesitate to contact Thép Bảo Tín. We are always ready to accompany your project!

Tiger Steel is a subsidiary of Bao Tin Steel.

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ