If you are looking into pneumatic ball valves to choose the right equipment for your automation system, from production lines, wastewater treatment plants, to fluid control systems, then this article is for you.

This type of valve is attracting significant attention from engineers and technicians due to its outstanding advantages, such as fast opening/closing, stable operation, and especially its independence from an electric power source. However, to make the right choice and maximise its usage efficiency, you need to understand its structure and operating principle fully. Check out the information below for more details!

What is a pneumatic ball valve?

A pneumatic ball valve is a type of ball valve combined with a pneumatic actuator to perform the automatic opening/closing function using compressed air, instead of manual operation with a lever

The valve structure consists of 2 main parts:

- Ball valve body: Typically made of stainless steel, plastic, or brass. It is commonly used to control the flow of liquids or gases.

- Pneumatic actuator: Uses air pressure to rotate the valve stem by 90 degrees. It helps the ball valve change its state from open to closed (or vice versa).

Pneumatic ball valves are highly valued for their quick opening/closing capability, stable operation, and independence from electricity. Therefore, they are ideal for automation systems in industrial applications, especially in environments that are prone to explosions or high humidity.

Structure of pneumatic ball valve

A pneumatic ball valve consists of two main parts: the ball valve and the pneumatic actuator. Depending on operational requirements, the system can also integrate additional accessories such as solenoid valves, pressure regulators, limit switches, etc.

Structure of the Ball Valve

The ball valve is the part that directly contacts the flow of liquids or gases, responsible for opening/closing the flow. Some key components include:

- Valve body: Made from materials such as stainless steel, cast iron, carbon steel, or PVC/UPVC, depending on the operating environment. The design can be two-piece or three-piece, with connection types like threaded, flanged, or welded.

- Ball (disc): A hollow spherical component with a through-hole for fluid flow. The ball can have either a full bore or a reduced bore. The surface is machined to ensure a high sealing performance.

- Valve stem: The connection between the ball and the actuator. The stem is usually made of stainless steel and is designed with a blowout-proof feature to enhance safety.

- Sealing gasket: Made from materials such as PTFE (Teflon), EPDM, Viton, etc., depending on pressure and type of fluid. The gasket prevents leakage and ensures a tight seal during valve operation.

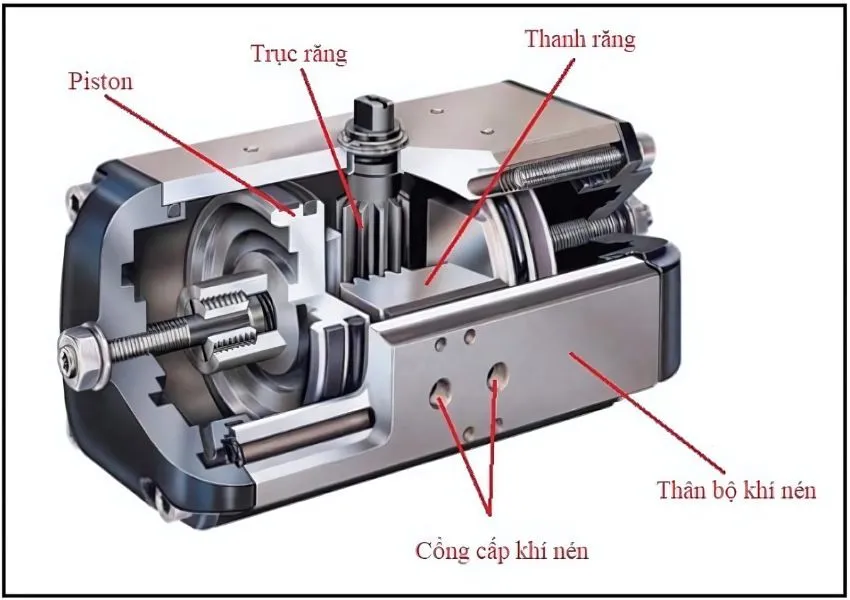

Structure of the Pneumatic Actuator

The pneumatic actuator is the part that allows the valve to operate automatically using compressed air as the input source. The main components include:

- Pneumatic actuator body: Usually made from aluminium alloy, it is corrosion-resistant, lightweight, yet sturdy.

- Piston and cylinder: The part that receives the compressed air to create pushing or pulling force, depending on whether the actuator is single-acting or double-acting.

- Gear and rack: These components convert the linear motion of the piston into rotational motion of the valve stem, ensuring precise opening/closing.

- Spring (only in single-acting actuators): Ensures that the valve automatically returns to a safe position (typically closed) when there is a loss of air supply.

- Drive shaft: Directly connects the pneumatic actuator to the ball valve stem, ensuring efficient motion transmission.

- Airports: Include air inlet and exhaust connections, typically labelled as A and B, or 1 and 2. These correspond to the control direction for opening/closing.

Accessories (if any)

To ensure the valve operates smoothly and can be integrated into an automated control system, it is often accompanied by auxiliary devices such as:

- Solenoid valve: Converts electrical signals into pneumatic signals, allowing remote control. Available in types like 3/2 and 5/2, suitable for both single-acting and double-acting valves.

- Air filter and pressure regulator: Ensures clean compressed air and stable pressure, preventing damage to the actuator.

- Limit switch: Provides feedback on the open/close status of the valve. It is essential when connected to a PLC system.

- Linear positioner: Used when the valve operates in modulation mode (not fully open/closed). It helps adjust the exact opening angle based on the input control signal.

Operating principle of pneumatic ball valve

The pneumatic control ball valve operates based on the smooth coordination between the ball valve and the pneumatic actuator (or controller). The key point is that it uses compressed air pressure to generate an automatic opening/closing force, instead of manual operation with a lever.

Operating principle of the pneumatic actuator

The pneumatic actuator is the “heart” of this automated system, converting compressed air energy into rotational motion to control the ball valve. There are two common types of pneumatic actuators:

Single-acting

This type uses compressed air for only one direction of motion (e.g., opening the valve), while the other direction is driven by the elastic force of a spring inside the actuator. When compressed air is supplied, the piston moves and compresses the spring, opening the valve. When the air supply is cut off, the spring automatically pushes the piston back to its original position, closing the valve.

Double-acting

This type uses compressed air for both directions of motion (opening and closing the valve). When compressed air is supplied to one port, it pushes the piston in one direction to open the valve. To close the valve, compressed air is supplied to the other port, pushing the piston in the opposite direction.

Ball valve mechanism

After the actuator generates rotational motion, this mechanism will act on the ball valve:

With an ON/OFF controller (Single-acting/Double-acting):

- When a control signal is received (usually from a solenoid valve), compressed air is supplied to the actuator.

- The compressed air pressure pushes the pistons inside the actuator.

- The linear motion of the pistons is converted into rotational motion through gears and a rack.

- The drive shaft of the pneumatic actuator will rotate by 90 degrees, simultaneously transferring this motion to the ball valve stem.

- As a result, the ball inside the valve will rotate by 90 degrees, changing its state from fully closed to fully open, or vice versa. This process happens very quickly, typically within a few seconds.

With a linear controller:

- In applications that require precise flow control (not just on/off), the ball valve will be equipped with a linear controller (positioner).

- The positioner receives input signals from the control system (most commonly 4-20mA current signals or 0-10V, 1-5V voltage signals).

- At this point, the positioner will adjust the compressed air pressure supplied to the actuator flexibly, not just for full opening/closing.

- The compressed air pressure is adjusted, which moves the piston and rotates the ball valve to a specific opening angle (e.g., 30 degrees, 45 degrees, 70 degrees…). This allows the flow rate to be modulated according to the precise requirements of the system.

🔥🔥For further reference:

Conclusion

The pneumatic control ball valve is an efficient and smart solution in automation systems, especially in environments that require fast, precise, and safe operation. With a sturdy design, quick opening/closing capability, and high sealing performance, this type of valve is increasingly being applied in various fields, including water treatment, chemicals, food, steam, and compressed air.

However, to ensure the system operates stably and durably, selecting high-quality products and reliable suppliers is a crucial factor.

Currently, Bao Tin Steel is a reputable distributor of genuine pneumatic control ball valves. In addition, we offer a wide range of specifications, types, and materials. We are committed to providing products with full certification documents, offering detailed consulting and pricing, and nationwide delivery. If you are looking for this type of valve, don’t hesitate to contact TBao Tin Steel for fast and accurate advice.

Tiger Steel is a subsidiary of Bao Tin Steel.

Tiếng Việt

Tiếng Việt ភាសាខ្មែរ

ភាសាខ្មែរ